10

ELECTRICAL CONNECTIONS

Use flexible cables according to EN 60 335-1

Regulations:

• if in PVC sheath, use at least H05 VV-F

• if in rubber sheath, use at least H05 RR-F.

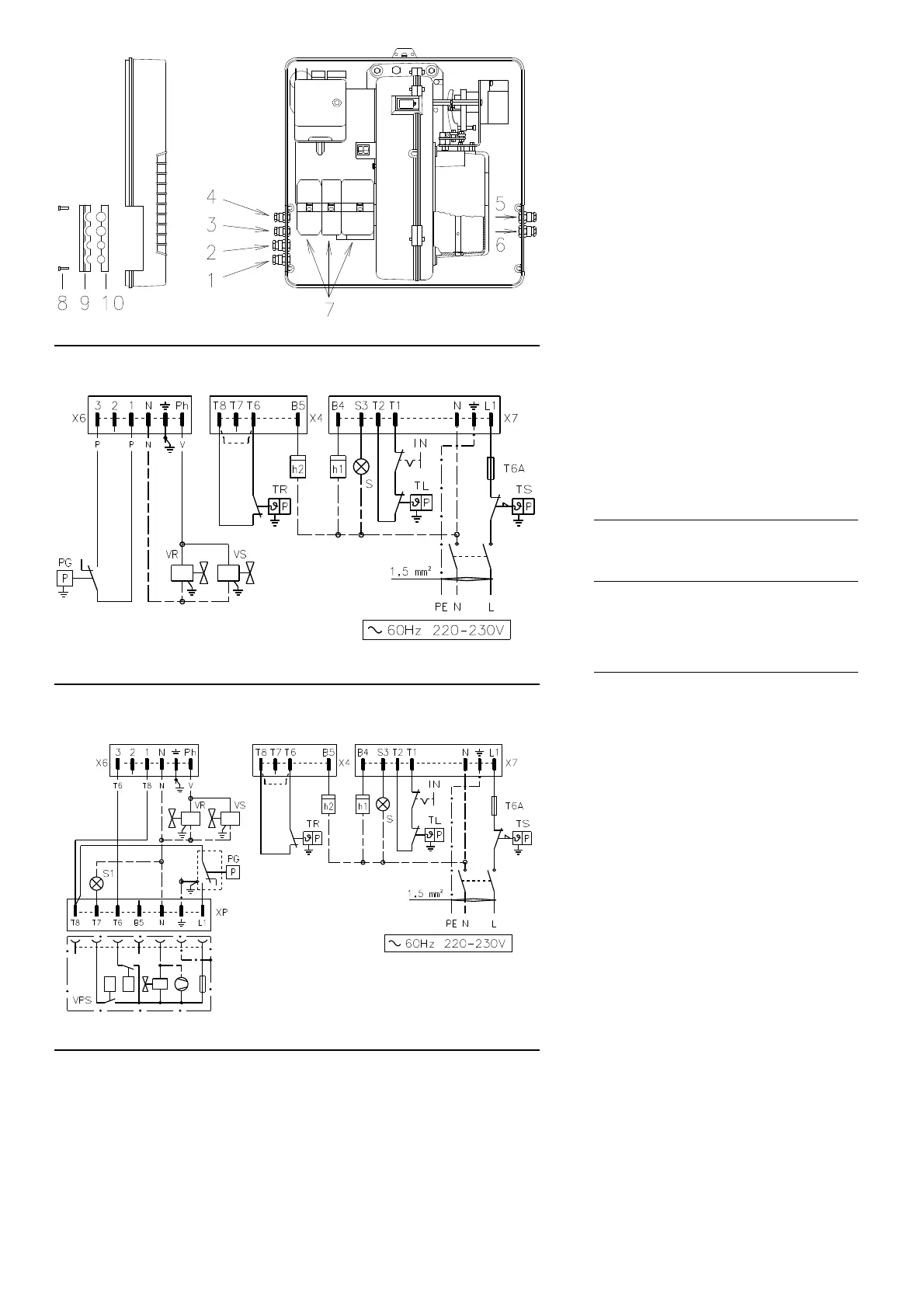

All the wires to connect to the burner plugs 7)(A)

must enter through the supplied fairleads, which

must be fitted into the relevant holes in the left

hand or right hand plate. To do this, first

unscrew screws 8), then split the plate into its

parts 9) and 10) and remove the menbrane

press-outs from the holes.

The fairleads and hole press-outs can be in var-

ious ways; the following lists show one possible

solution:

RS 28 und RS 38 single-phase

1 -Pg 11 Single-phase power supply

2 -Pg 11 Gas valves

3 -Pg 9 Remote control device TL

4 -Pg 9 Remote control device TR

5 -Pg 11 Gas pressure switch or gas valve

leak detection control device

RS 38 three-phase and RS 50

1 -Pg 11 Three-phase power supply

2 -Pg 11 Single-phase power supply

3 -Pg 9 Remote control device TL

4 -Pg 9 Remote control device TR

5 -Pg 11 Gas valves

6 -Pg 11 Gas pressure switch or gas valve

leak detection control device

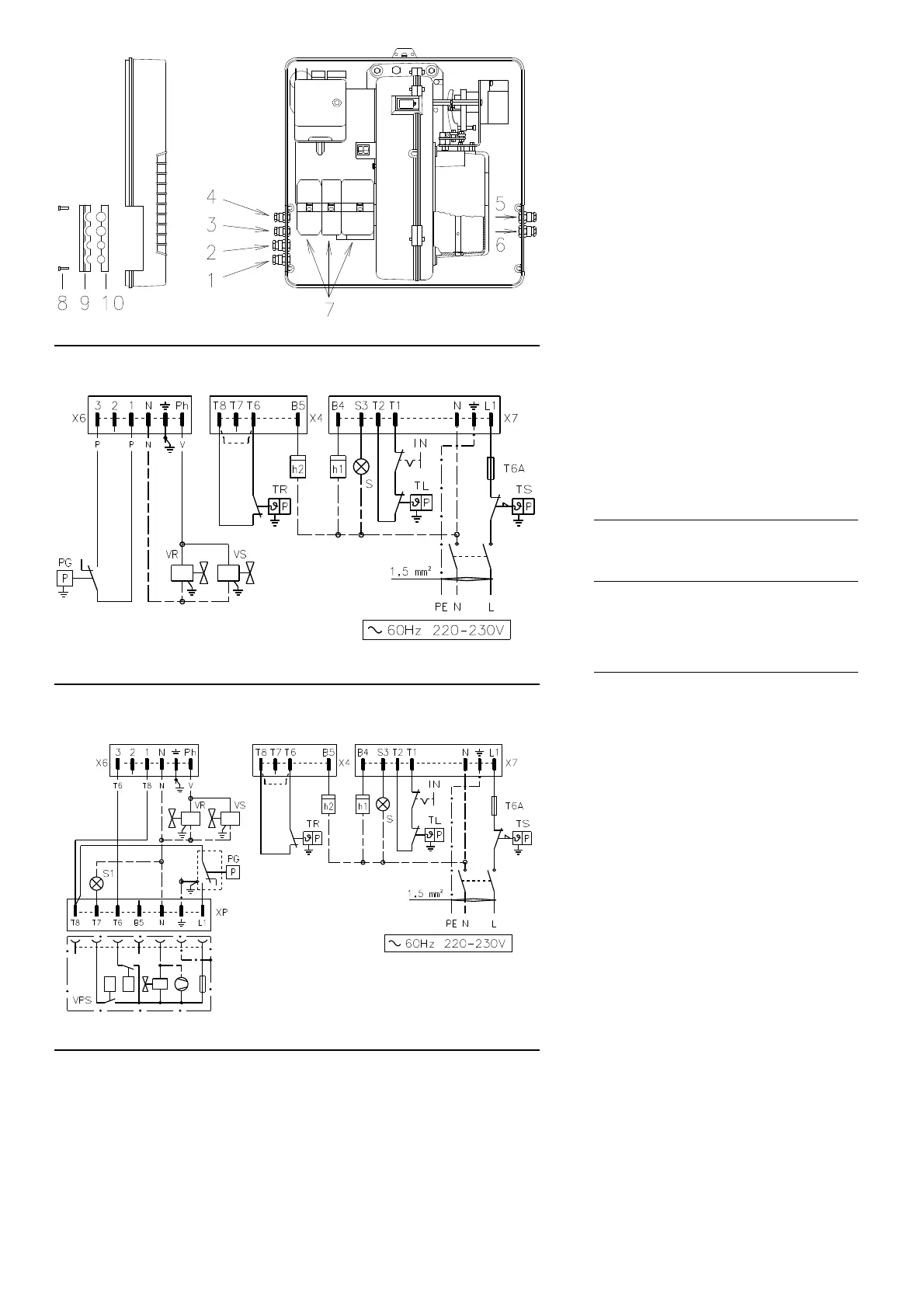

LAYOUT (B) - The RS 28 - 38 Models electrical

connection single-phase power supply

without leak detection control device.

LAYOUT (C) The RS 28 - 38 Models electrical

connection single-phase power supply

with VPS leak detection control device.

Gas valve leak detection control takes place

immediately before every burner start-up.

Key to layouts (B) - (C)

h1 - 1st stage hourcounter

h2 - 2nd stage hourcounter

IN - Burner manual stop switch

XP- Plug for leak detection control device

X4 - 4 pole plug

X6 - 6 pole plug

X7 - 7 pole plug

PC- Gas pressure switch for leak detection con-

trol device

PG- Min. gas pressure switch

S - Remote lock-out signal

S1 - Remote lock-out signal of leak detection

control device

TR- High-low mode load remote control system:

controls operating stages 1 and 2.

If the burner is to be set up for single stage

operation, replace of remote control device

TR with a jumper.

TL - Load limit remote control system:

shuts down the burner when the boiler tem-

perature or pressure reaches the preset

value.

TS- Safety load control system:

operates when TL is faulty

VR- Adjustment valve

VS- Safety valve

(A)

(B)

RS 28 - RS 38 single-phase without leak detection control device

RS 28 - RS 38 single-phase with leak detection control device VPS

(C)

D3027

D3161

D3162

Loading...

Loading...