11

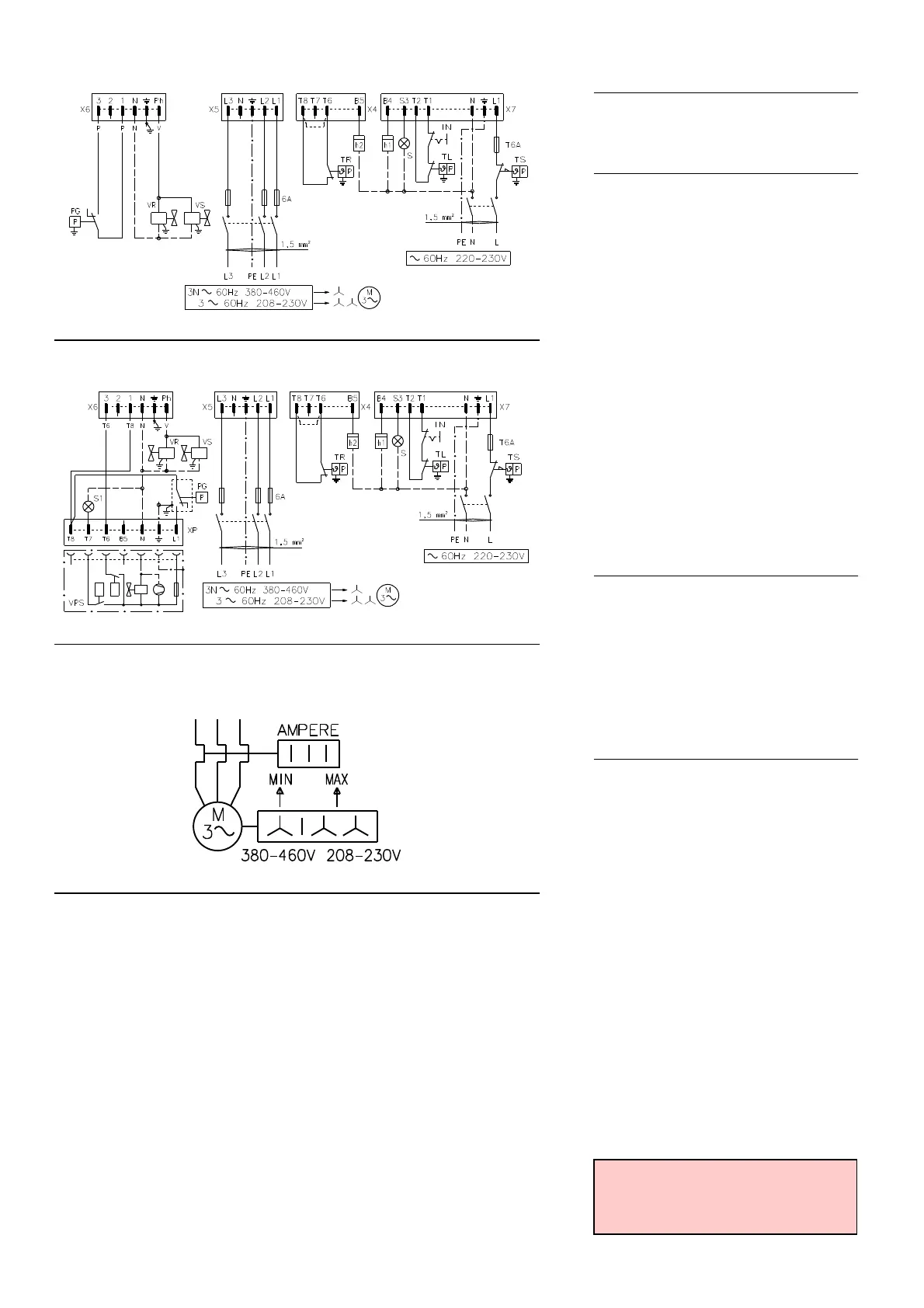

LAYOUT (A) - The RS 38 - 50 Models electri-

cal connection three-phase power supply

without leak detection control device

LAYOUT (B) - The RS 38 - 50 Models electri-

cal connection three-phase power supply

with VPS leak detection control device.

Gas valve leak detection control takes place

immediately before every burner starting.

Key to layouts (A) - (B)

h1 - 1st stage hourcounter

h2 - 2nd stage hourcounter

IN - Burner manual stop switch

XP- Plug for leak detection control device

X4 - 4 pole plug

X5 - 5 pole plug

X6 - 6 pole plug

X7 - 7 pole plug

PC- Gas pressure switch for leak detection con-

trol device

PG- Min. gas pressure switch

S - Remote lock-out signal

S1 - Remote lock-out signal of leak detection

control device

TR- High-low mode load remote control system:

controls operating stages 1 and 2.

If the burner is to be set up for single stage

operation, replace of remote control device

TR with a jumper.

TL - Load limit remote control system:

shuts down the burner when the boiler tem-

perature or pressure reaches the preset

value.

TS- Safety load control system:

operates when TL is faulty

VR- Adjustment valve

VS- Safety valve

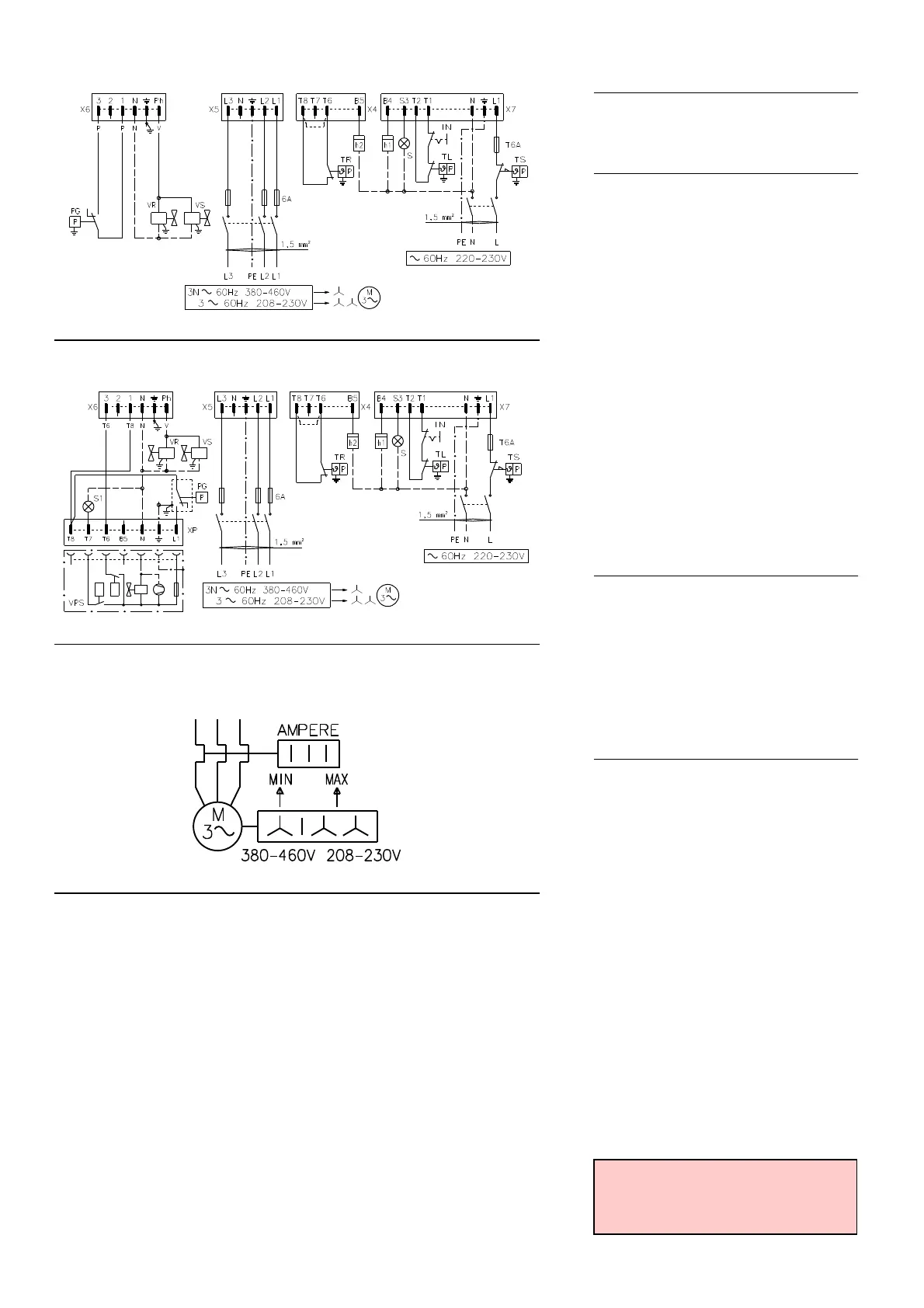

LAYOUT (C)

Calibration of thermal cut-out 20)(A)p.3

This is required to avoid motor burn-out in the

event of a significant increase in power absorp-

tion caused by a missing phase.

• If the motor is double star-powered, 380-460

V, the cursor should be positioned to "MIN".

• If the motor is star-powered, 208-230 V, the

cursor should be positioned to "MAX".

Even if the scale of the thermal cut-out does not

include rated motor absorption at 380-460 V,

protection is still ensured in any case.

N.B.

• The RS 38 and RS 50 three-phase leave the

factory preset for 380-460 V power supply. If

208-230 V power supply is used, change the

motor connection from star to double star

and change the setting of the thermal

cut-out as well.

• The supply to the auxiliary circuits must be

220-230 V.

• The RS 28-38-50 burners have been type-

approved for intermittent operation. This

means they should compulsorily be stopped

at least once every 24 hours to enable the

control box to check its own efficiency at start-

up. Burner halts are normally provided for

automatically by the boiler load control sys-

tem. If this is not the case, a time switch

should be fitted in series to IN to provide for

burner shut-down at least once every 24

hours.

• The RS 28-38-50 burners are factory set for

two-stage operation and must therefore be

connected to control device TR. Alternatively,

if single stage operation is required, instead of

control device TR install a jumper lead

between terminals T6 and T8 of connector X4.

WARNING: Do not invert the neutral with

the phase wire in the electricity supply

line. Inverting the wires will make the

burner go into lock-out because of firing

failure.

(A)

(B)

RS 38 - RS 50 three-phase without leak detection control device

RS 38 - RS 50 three-phase without leak detection control device VPS

(C)

CALIBRATION OF THERMAL RELAY

RS 38 three-phase - RS 50

D3163

D3164

D3165

Loading...

Loading...