Linear installation guide 13563-B 02-19 | 39

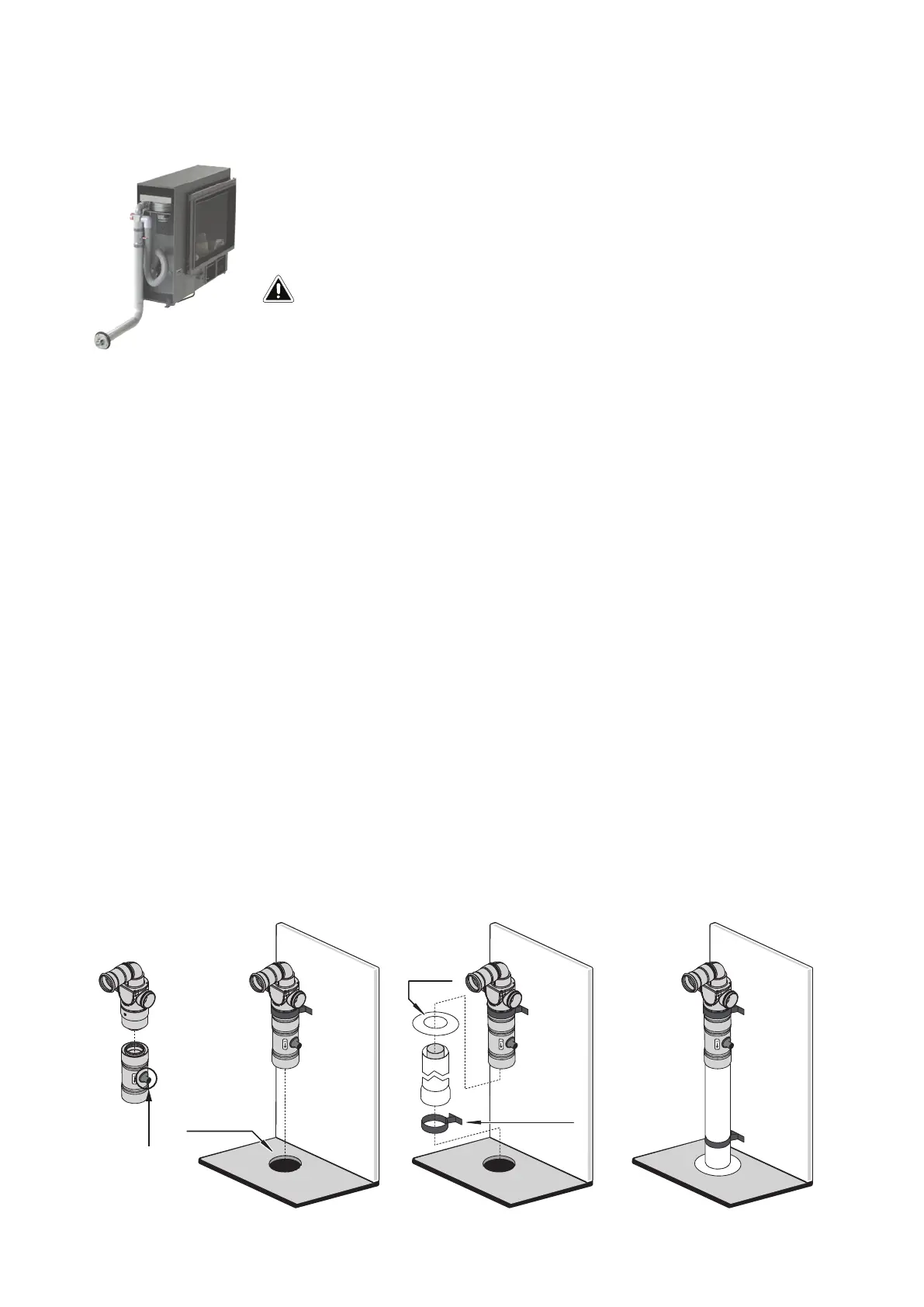

down-and-out ueing

Flueing options

The down and out ue allows for the adaption ue component to face

downwards, and for the ue to run vertically through a hole in the oor, and

then terminate horizontally outside—ue must terminate 300 mm above the

ground.

I

n

t

e

r

i

o

r

wa

l

l

I

n

te

ri

o

r

wa

l

l

Wall plate

Stand off clip

I

n

t

e

r

i

o

r

w

a

l

l

Floor penetration

Ø 80 mm

Cap off the drain

tube with a small

cable tie

Overview of installation steps

1. Lubricate all inner pipe o-rings with the silicone grease provided.

2. Join the ue transition and condensate together ensuring the condensate arrow points

downwards. Even though the condensate is not actually connected in this ue arrangement,

the condensate component serves as a transition piece between the transition casting and the

ue pipe. The transition component must not be connected directly to the ue pipe due to the

heat of the ue gases. Cap off the condensate drain tube with the cable tie supplied.

3. Fit lengths of ue pipe as required.

4. The ue penetration should have made at the same time as the cutout for the gas connection.

Floor penetration should be a 80 mm diameter hole—ensure edges are smooth.

5. Pass the ue pipe through the wall plate and through the oor penetration, and secure the wall

plate in place to seal the oor.

6. Prepare the horizontal section of the ue system under the oor by connecting the ue pipe

and bends as required. Allow for a 2° continuous fall from the rst section of the horizontal ue

pipe to the wall penetration.

7. Create the wall terminal, refer p. 41, ensuring a 300 mm clearance between the ue terminal

and ground level.

8. Secure joints between the ue components through the outer pipes with screws and secure the

entire ue system using the wall straps supplied.

300 mm minimum of straight ue is required before any bends. This is

required due to heat produced from the initial section of the ue.

IMPORTANT

Loading...

Loading...