GD-70D - 86 -

10

Maintenance

This is a critical instrument for incident prevention and safety.

To maintain the performance of the detector and improve its reliability, perform regular maintenance.

NOTE

To use the pyrolyzer unit (PLU-70), also refer to the individual operating manual.

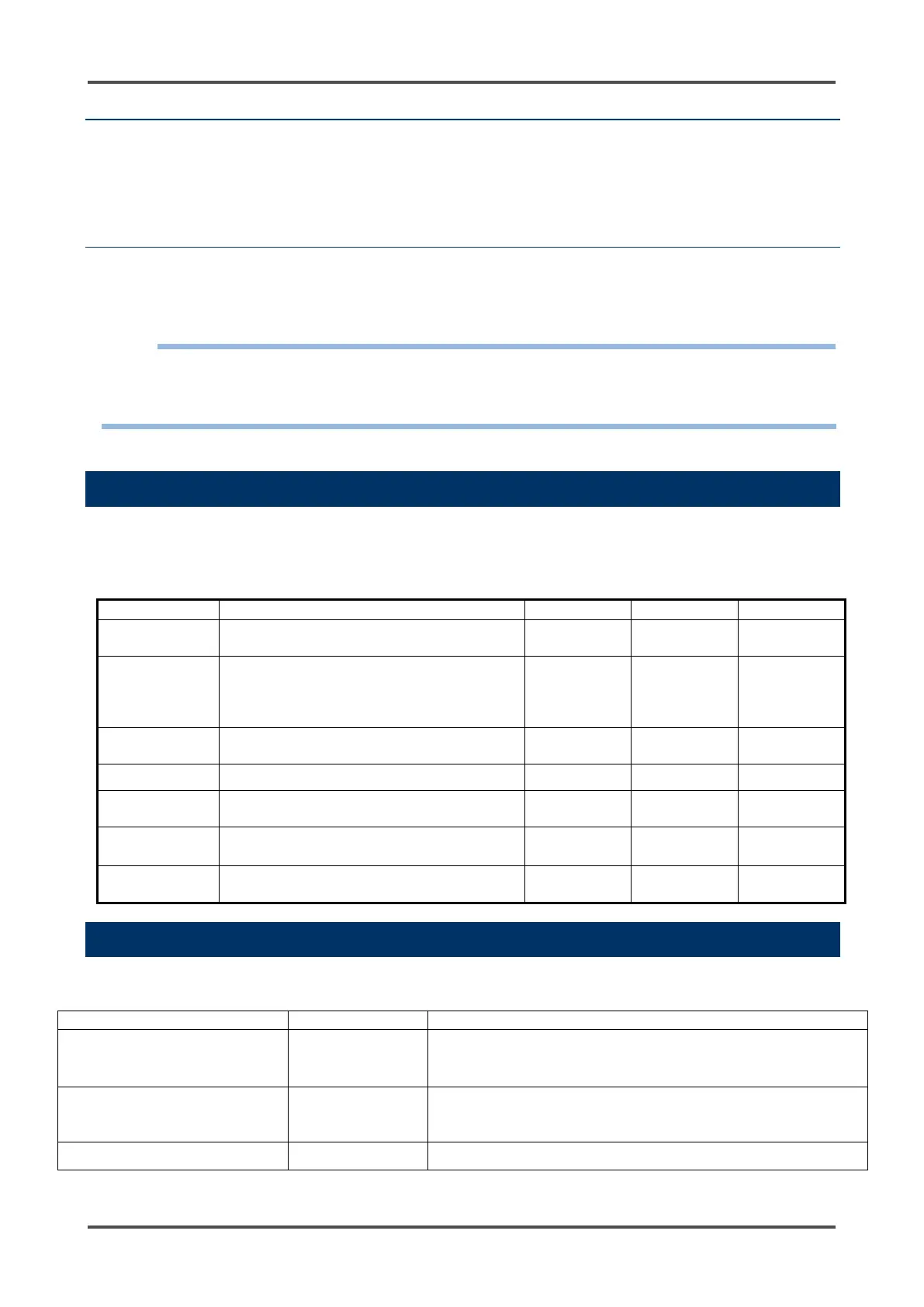

10-1 Maintenance intervals and items

• Daily maintenance: perform maintenance before beginning to work.

• Monthly maintenance: perform maintenance on the alarm circuit (alarm test) once a month.

• Regular maintenance: perform maintenance once every six months.

Verify that the power lamp lights up.

display check

Verify that the gas reading is zero (or

20.9 vol% for oxygen). If the reading is

not zero (or 20.9 vol%), perform a zero

See the flow rate indicator to check for

abnormalities.

Check the dust filter for dust or clogging.

Inspect the alarm circuit by using the

alarm test function.

adjustment

Perform a span adjustment using

calibration gas.

Check alarm operation using calibration

gas.

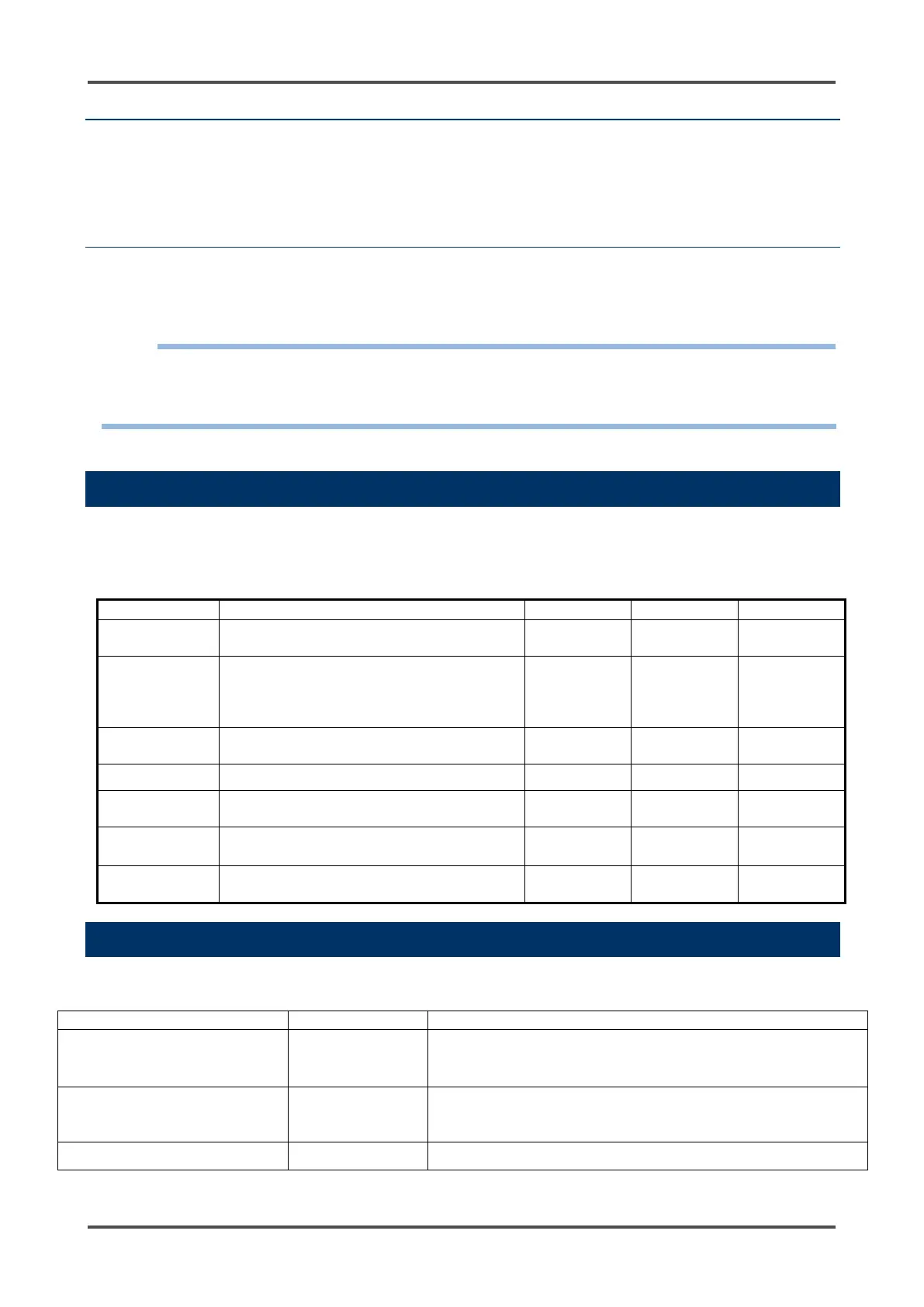

10-2 Calibration Overview

Calibration instructions depend on the GD-70D you are calibrating. The table below will tell you what

calibration instructions to use based on your GD-70D’s detection gas and range.

AsH3 (Arsine) 0 - 0.20 ppm Calibrating with a Surrogate Gas (Sensors with Factors) on

page 93

B2H6 (Diborane) 0 - 0.30 ppm Calibrating with a Surrogate Gas (Sensors with Factors) on

page 93

BCl3 (Boron trichloride) 0 - 15.0 ppm Calibrating with a Gas Bag (Calibrating with HCl) on page 99

Loading...

Loading...