Rockwell Automation Publication 7000L-UM301F-EN-P - March 2020 419

Catalog Number Explanation Appendix A

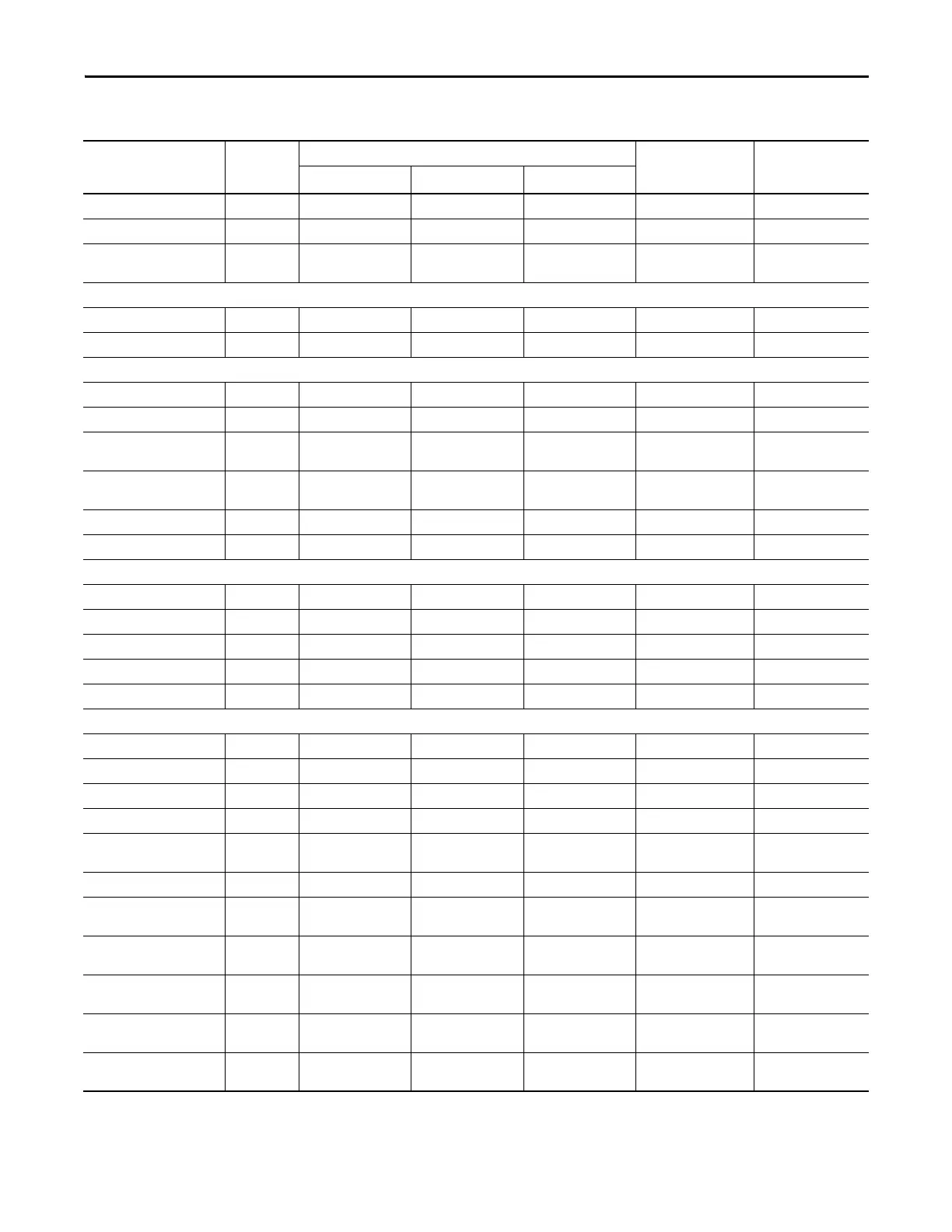

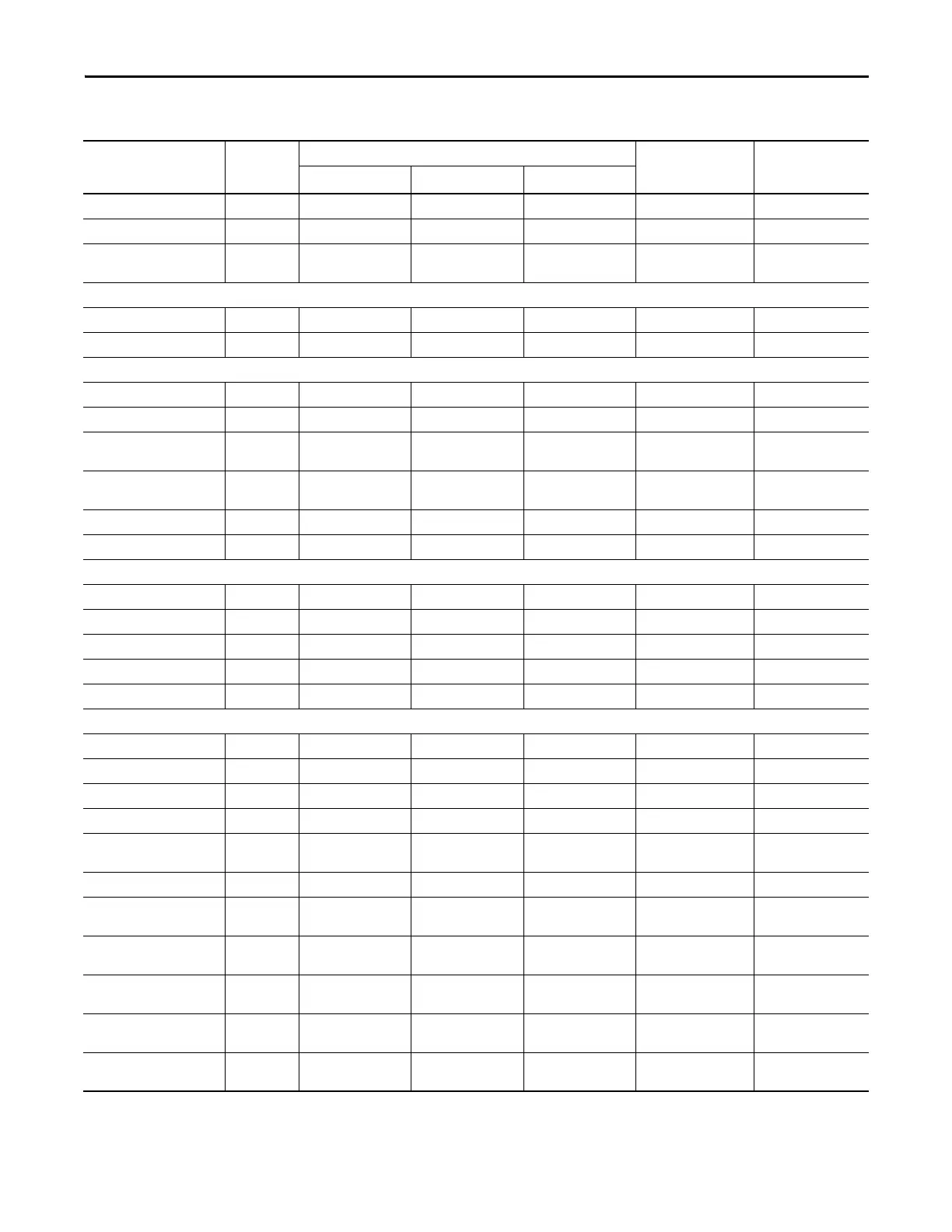

Screw type, loaded CT 200 100 100 Contact factory Yes

DRAG LINE CT 100 200 200 Contact factory Yes

EXTRUDERS

(rubber or plastic)

CT 150 150 100 Contact factory Yes

FANS (centrifugal, ambient)

Damper closed VT 25 60 50 Normal No

Damper open VT 25 110 100 Normal No

FANS (centrifugal, hot gases)

Damper closed VT 25 60 100 Normal No

Damper open VT 25 200 175 Contact factory No

FANS

(propeller, axial flow)

VT 40 110 100 Normal No

GRINDING MILL

(Ball/Sag Mill)

CT 175 180 100 Contact factory Yes

HOISTS CT 100 200 200 Contact factory Yes

KILNS (rotary, loaded) CT 250 125 125 Contact factory Yes

MIXERS

Chemical CT 175 75 100 Contact factory Yes

Liquid CT 100 100 100 Heavy Yes

Slurry CT 150 125 100 Heavy Yes

Solids CT 175 125 175 Contact factory Yes

PULPER VT 40 100 150 Contact factory No

PUMPS

Centrifugal, discharge open VT 40 100 100 Normal No

Oil field Flywheel CT 150 200 200 Contact Factory Yes

Propeller VT 40 100 100 Normal No

Fan Pump VT 40 100 100 Norma No

Reciprocating / Positive

Displacement

CT 175 30 175 Contact factory Yes

Screw type, started dry VT 75 30 100 Normal No

Screw type, primed, discharge

open

CT 150 100 1000 Heavy Yes

Slurry handling, discharge

open

CT 150 100 100 Heavy Yes

Turbine, Centrifugal, deep-

well

VT 50 100 100 Normal No

Vane-type, positive

displacement

CT 150 150 175 Contact factory Yes

SEPARATORS, AIR

(fan type)

VT 40 100 100 Normal No

(1) PowerFlex 7000 “A” Frame suitable only for normal service duty rating.

Table 33 - Typical Application Load Torque Profiles (Continued)

(1)

Application Load Torque

Profile

Load Torque as Percent of Full-Load Drive Torque Required Drive

Service Duty Rating

Encoder Required for

Extra Starting

Torque?

Break-away Accelerating Peak Running

Loading...

Loading...