334 Rockwell Automation Publication 7000L-UM301F-EN-P - March 2020

Chapter 5 Component Definition and Maintenance

Piping, Tubing and Connectors

The piping is schedule 80 made from chlorinated polyvinyl chloride (CPVC)

which has good high and low temperature properties and is unaffected by de-

ionized water or ethylene glycol. The main piping is either 1.5 inch (38 mm) or

2.0 inch (50 mm) diameter.

The coolant hose connecting chill blocks to manifolds and Common Mode

Chokes or DC Links to piping is made of 10 mm (3/8") EPDM. The hose is

pushed onto hose barbs of stainless steel or CPVC. Hose clamps are used at the

hose barbs.

Non-Return Valves

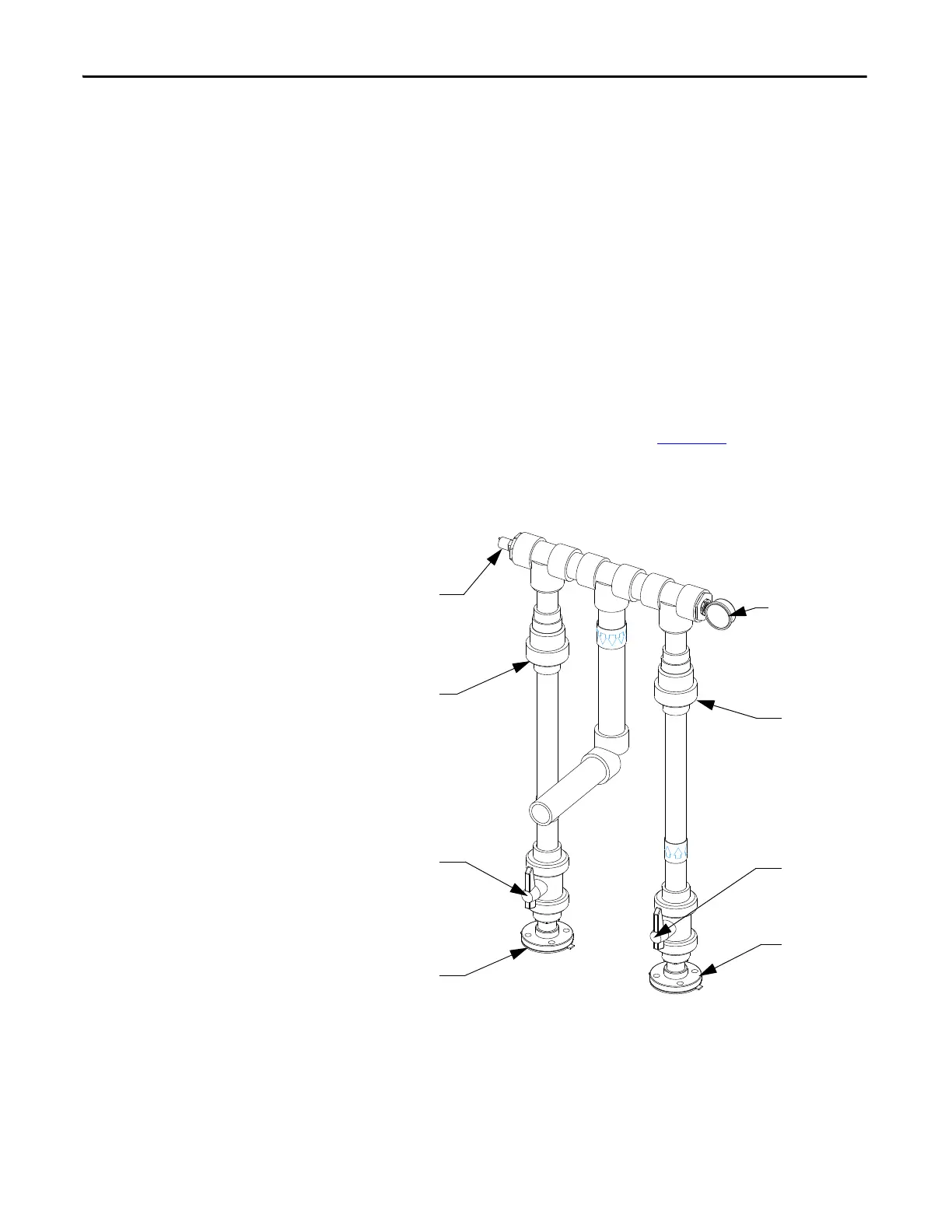

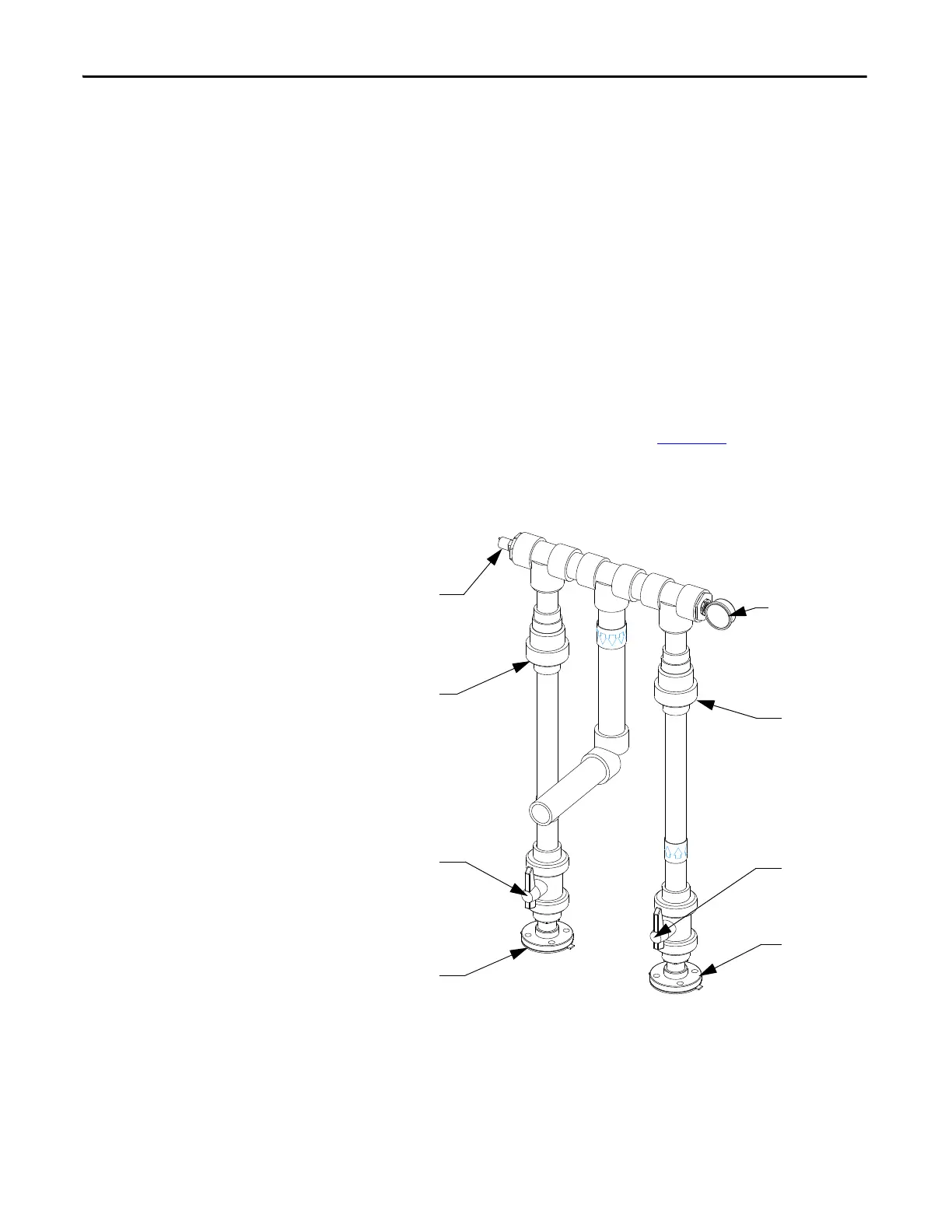

The non-return valves (NV1 & NV2) shown in Figure 279 are ball-type valves

made from CPVC. These can not be changed with the drive on-line. All coolant

must be drained to replace these parts.

Figure 279 - Pressure Indicator and Switch Locations

Pressure Indicator PI

NV2

V12

From P2

From P1

V11

NV1

Pressure Switch PS

Loading...

Loading...