86 Rockwell Automation Publication 7000L-UM301F-EN-P - March 2020

Chapter 2 Drive Installation

Information Regarding Termination of Customer Cables

Customer termination assemblies can accommodate either top or bottom

customer cable entry.

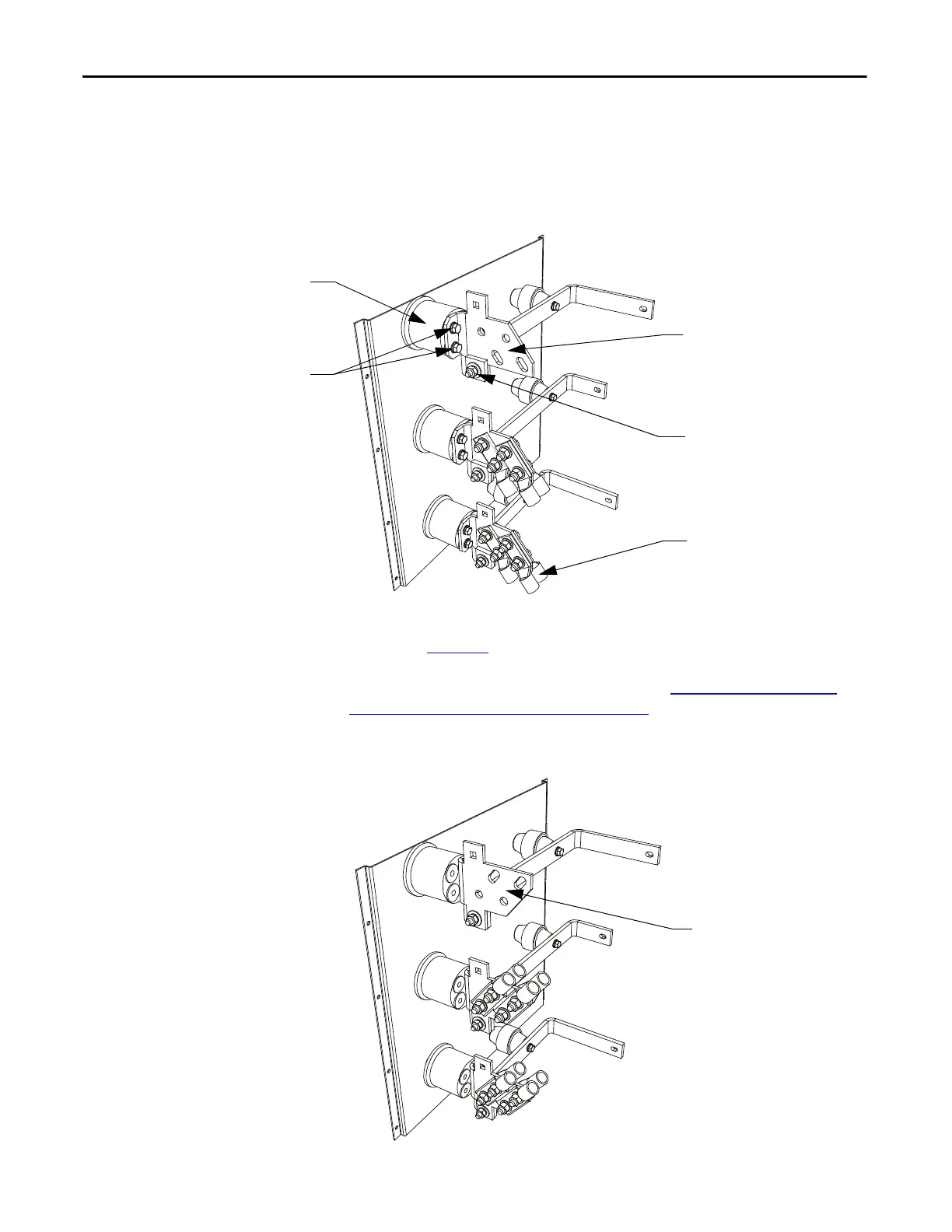

Figure 68 - Typical Line Cable Termination (shown assembled for bottom cable entry – 18 Pulse)

For top line cable entry, it is necessary to remove the lug pads and re-orient them

as shown in Figure 69

. To remove the lug pads, disconnect the M10 bus

connection hardware (17 mm hex tooling required). Remove the two bolts that

secure the lug pad to the 4-hole insulator. Refer to

Torque Requirements for

Threaded Fasteners on page 421 (Appendix B) for Torque Values of electrical

connections.

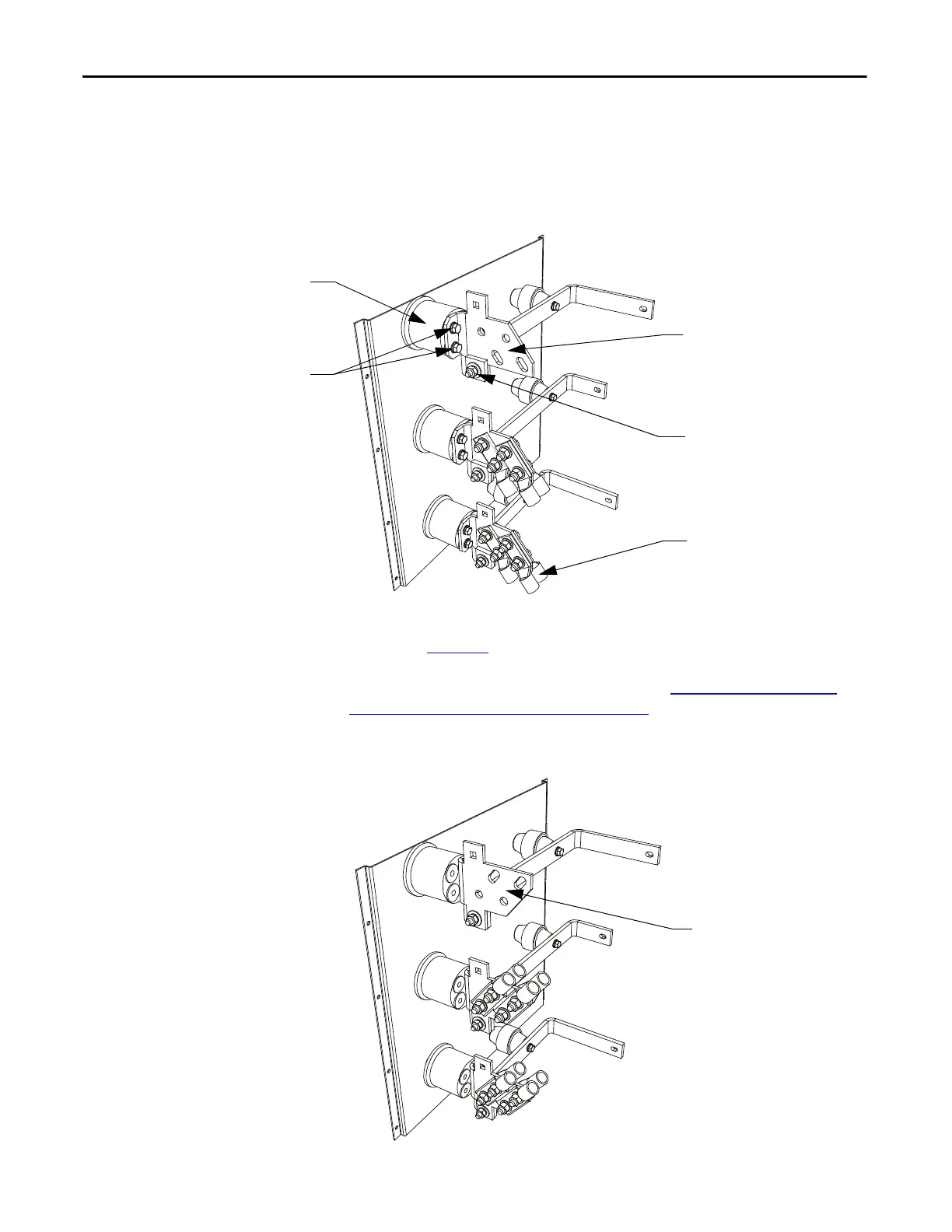

Figure 69 - Typical Line Cable Terminal Assembly (modified for top cable entry – 18 Pulse)

4-hole Insulator

Bolts

Lug pad shown with bottom

cable entry orientation

M10 bus

connection

hardware

Customer supplied lugs

4 lugs per phase maximum

Lug pad oriented for

top cable entry

Loading...

Loading...