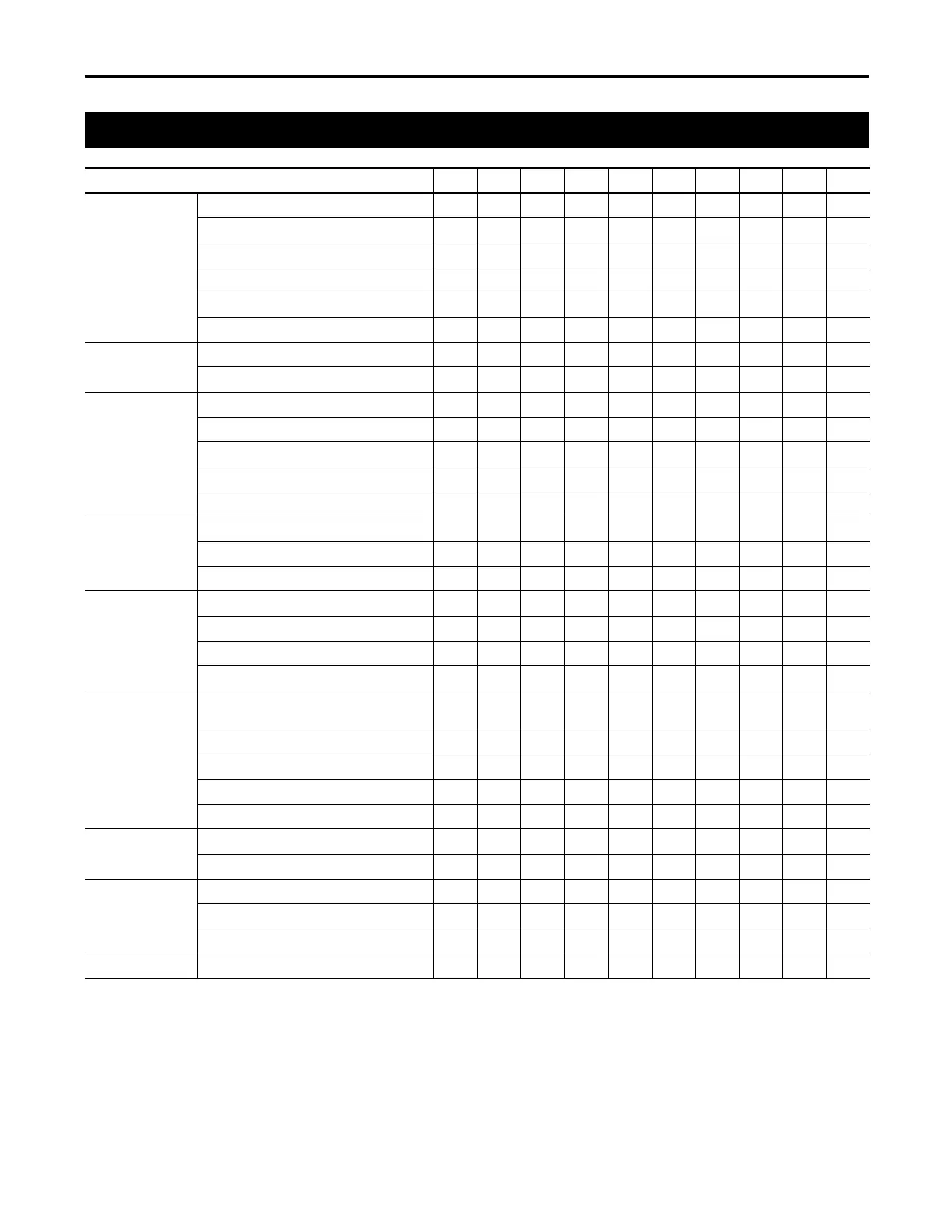

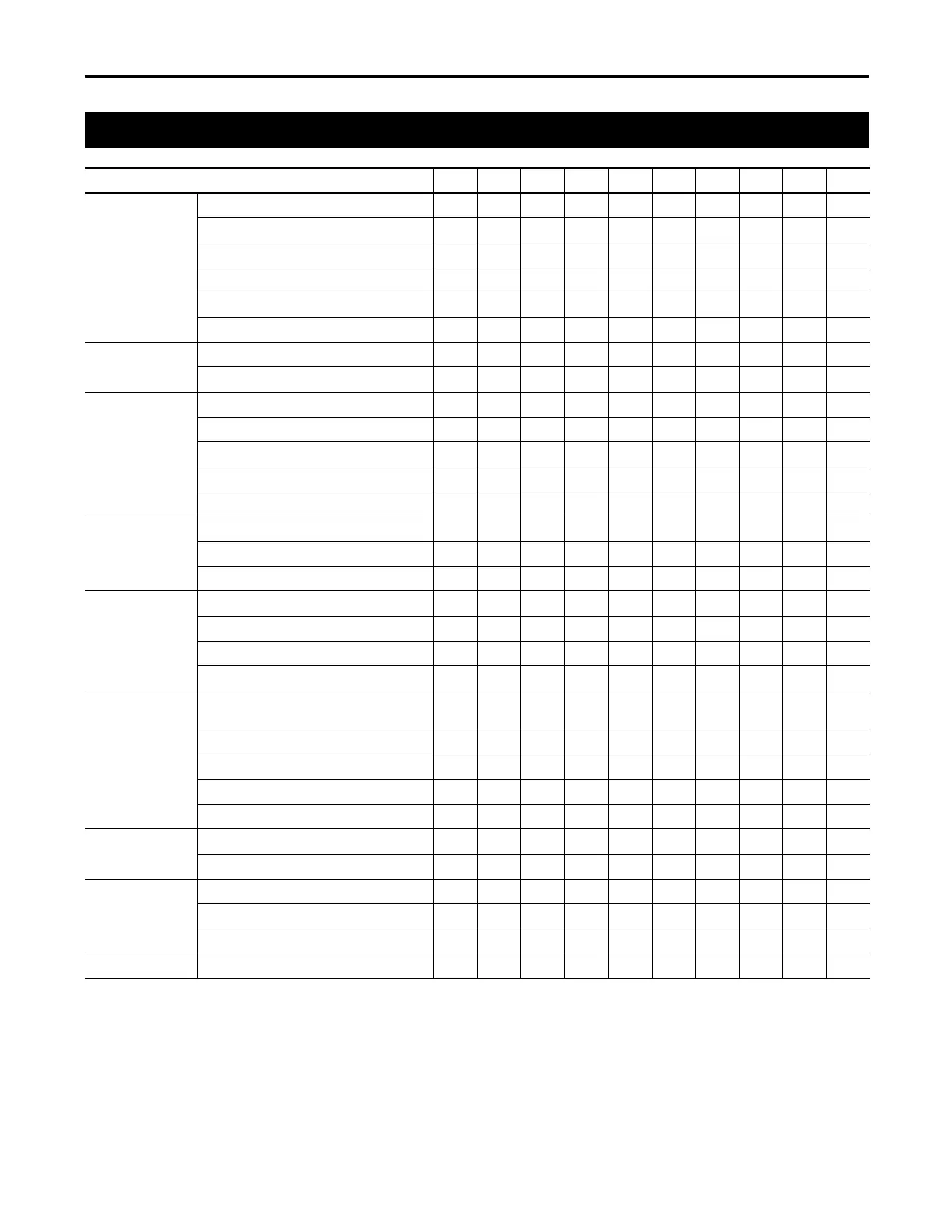

Rockwell Automation Publication 7000L-UM301F-EN-P - March 2020 431

Preventative Maintenance Schedule Appendix D

Rockwell Automation PowerFlex 7000 Preventative Maintenance Schedule

Period Interval (Years) 11121314151617181920

Liquid-Cooling System Mesh Filters

(1)

CCCCCCCCCC

De-ionizing Filter Cartridge

(1)

RRRRRRRRRR

All Fittings/Connections/Hose Clamps IIIIIIIIII

Redundant Cooling Pump Motors/Pumps IIIIIIIIII

Redundant Cooling Pump Motor Seals IIIIIIIIII

Thermostatic Valve Element IIIRIIIIII

Auxiliary Cooling

System

Door Mounted Air Filters

(1)(2)

C/R C/R C/R C/R C/R C/R C/R C/R C/R C/R

Small Aux. Cooling Fans “Caravel” IIIIRIIIII

Power Switching

Components

Power Devices (SGCTs/SCRs) IRIIIIIIII

Snubber Resistors/Sharing Resistors/HECS IIIIIIIIII

Rectifier Snubber Capacitors

(3)(4)

II/R

(4)

IIII/R

(4)

II II

Inverter Snubber Capacitors

(5)(6)

IIIIIIIIII

Integrated Gate Driver Power Supply IIIIRFB/RIIIII

Integral Magnetics/

Power Filters

Isolation Transformer/Line Reactor IIIIMIIIII

DC Link/CMC IIIIMIIIII

Line/Motor Filter Capacitors IIIIMIIIII

Control Cabinet

Components

AC/DC and DC/DC Power Supplies IIIIRFB/RIIIII

Control Boards IIIIIIIIII

Batteries (DPM) IRIIRIIRII

Battery Module (UPS)

(7)

IIIIRIIIII

Connections Low Voltage Terminal Connections/

Plug-in Connections

IIIIIIIIII

Medium Voltage Connections IIIIIIIIII

Chillblock Bolted Connections IIIIIIIIII

Medium Voltage Connections (Rectifier)

(3)

–I

(3)

–––I

(3)

––––

Medium Voltage Connections (Inverter)

(5)

––––––––––

Enhancements Firmware –Rv––Rv––Rv––

Hardware –Rv––Rv––Rv––

Operational ConditionsParameters IRvIIRvIIRvI–

Variables IRvIIRvIIRvI–

Application Concerns IRvIIRvIIRvI–

Spare Parts Inventory/Needs IRvIIRvIIRvI–

(1) These components may be serviced while the VFD is running.

(2) If filter supplied is not a washable type, replace filter. If filter supplied is a washable type, wash or replace (depending on state of filter).

(3) When rectifier snubber capacitors are replaced, the MV connections for the rectifier need to be inspected.

(4) A 4-year rectifier snubber capacitor replacement interval applied only to drives with 18-pulse rectifiers shipped before 2012 (rectifier snubber capacitors are blue). However, current enhanced

replacement rectifier snubber capacitors extend this to a 10-year replacement interval (replacement rectifier snubber capacitors are black). A 10-year rectifier snubber capacitor replacement interval has

always applied to drives with AFE rectifiers.

(5) When inverter snubber capacitors are replaced, the MV connections for the inverter need to be inspected.

(6) A 10-year inverter snubber capacitor replacement interval applies to all drive configurations.

(7) Replace UPS batteries annually for 50°C rated VFDs.

Loading...

Loading...