Traction transmission

Engine power is transmitted to the consecu-

tive work and drive pumps by means of a flexi

switch. From the pump to the hydraulic motor

of the gear box the power is transmitted by

means of liquid. The pump output is adjusted

steplessly using the drive pedal between posi-

tions 0 and +/- maximum.

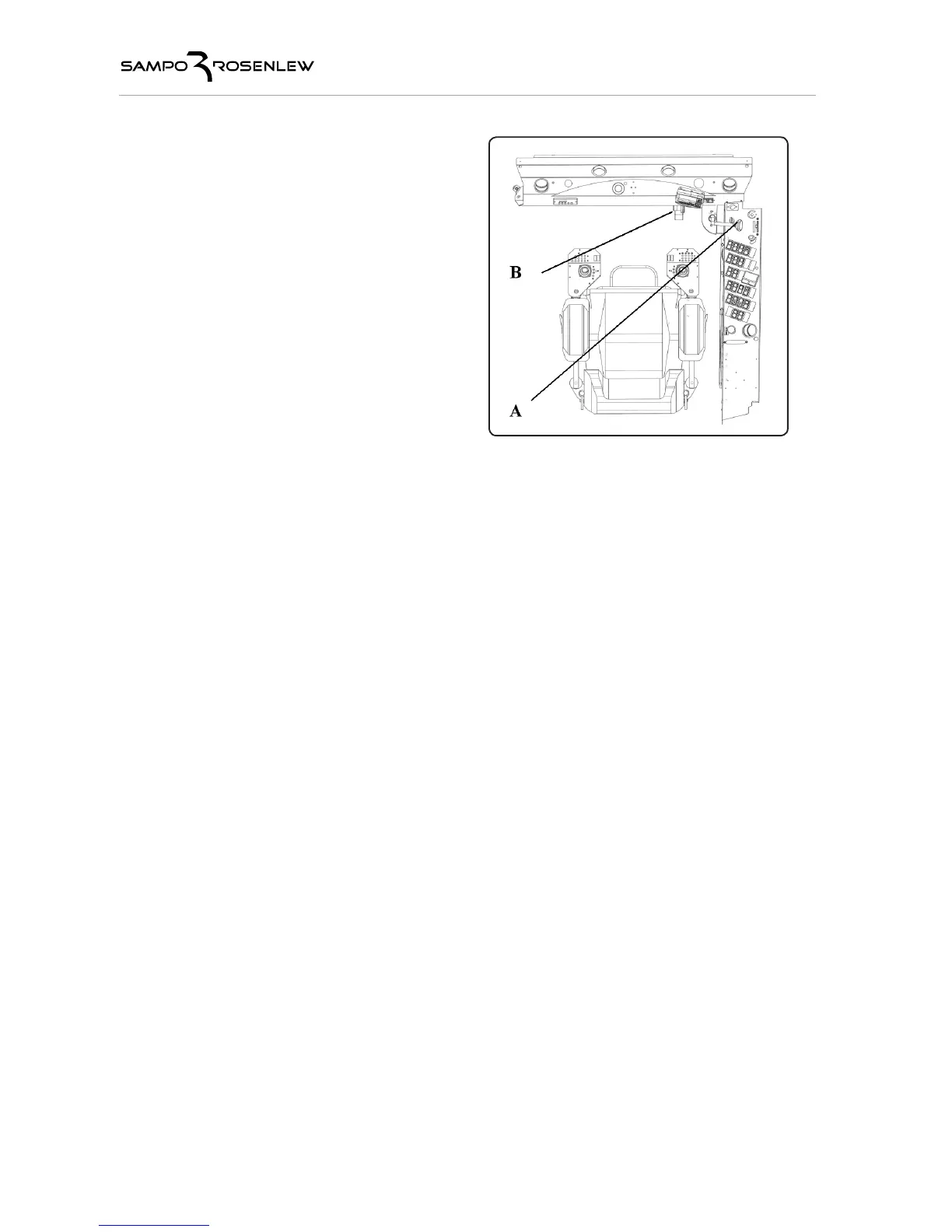

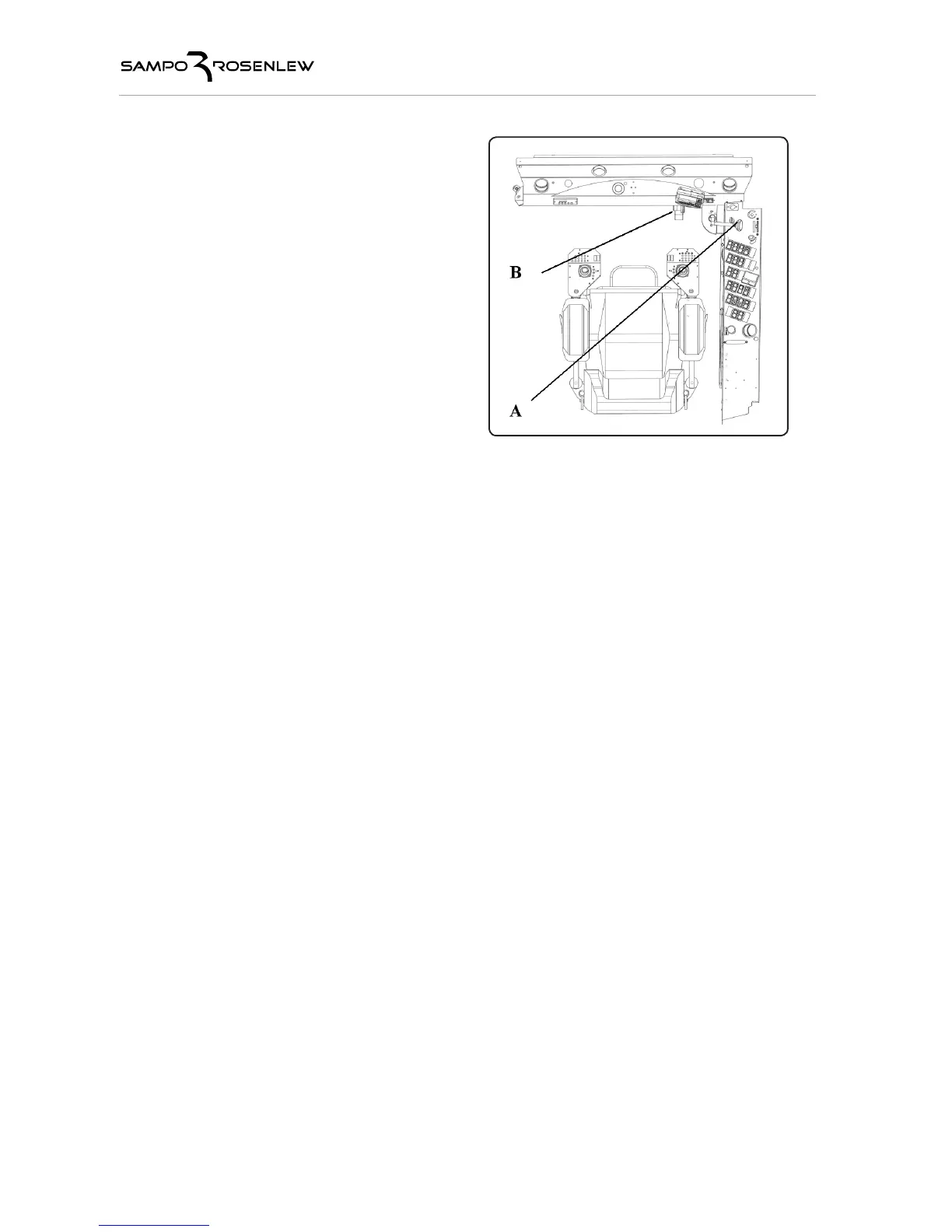

There are three gear speed ranges, which are

selected using lever A, fig. 13. The ranges are

intended for harvesting (range 1 with the gear

lever down pulled backward), driving in the

forest (range 2 with the gear lever up pushed

forward), and driving on the road (range 3 with

the gear lever down pushed forward). Gears

should be shifted on level ground without pres-

sing drive pedal B. From the gearbox power is

transmitted to the front wheels by means of

the drive shafts and the final drives.

The speed of the harvester is controlled by drive pedal B. When the pedal is not pressed, the

harvester is stationary if the gear is engaged and the engine running.

Driving direction (forward/backward) is chosen by switch close to left joystick (switch A, picture

13a). Drive direction forward is selected by pushing switch forward. Correspondingly drive direc

-

tion backwards is selected by pushing switch backwards. Speed is controlled by pedal. Also the

engine speed (r/min) and potentiometer B (fig 13a) near left joystick affect the speed.

When driving in traffic, the harvester head should be kept close to the harvester and tied. The

harvesting computer should be switched off in case of unintended crane movements.

A forest harvester equipped with hydrostatic transmission must never be parked using

only the gear, but the parking brake must always be engaged. The hydraulic motor

cannot keep the harvester stationary for a long period.

Four wheel drive

Rear-wheel drive is switched on electrically using switch N on the right-side instrument panel,

fig. 2. The coupling shall be done with the harvester stationary. 4WD is available on gears 1

and 2. When towing the harvester, four-wheel drive must be off and the engine running to allow

the wheel motors to be disengaged. Short-distance towing at a low speed is permitted if the

engine and the drive pump cannot be kept running.

Differential and rear- wheel drive lock

There are often situations when both the wheels on the front or rear axle do not have sufficient

grip in respect to the required traction power. In this case one of the wheels stops gripping,

which will further decrease the traction power. This can be avoided by engaging either the front

lock using switch P (fig. 2) and/or the 4WD lock using switch O, (fig. 2). The engagement of the

4WD lock generates anti-skid between the front and the rear. This also engages the hydrau-

lic lock between the rear wheels. The 4WD lock does not hold 100 %. Thus it allows different

wheels to turn at a different speed. On solid ground the 4WD lock makes turning difficult, so it

should be switched off. The mechanical differential lock at the front should also be disengaged

before sharp turns. The front mechanical lock can be switched on when the machine is stopped

and it can be used on gears 1 and 2. The four wheel drive lock is only available on gear 1.

Loading...

Loading...