Service measures weekly or every 50 hours

1. All daily service measures

The service measures to be taken every 50 hours include all the measures listed in service

measures daily or every 8 hours.

2. Lubrication in compliance with the lubrication table

Lubricate in compliance with the lubrication table paying attention to any special instructions.

See the lubrication table.

Service measures every 100 hours

1. Cleaning of engine air filter

The engine suction air is cleaned by a pre-filter and a dry paper filter of a dual-element type.

Faultless functioning of the filter is of utmost importance to the long lifespan of the engine.

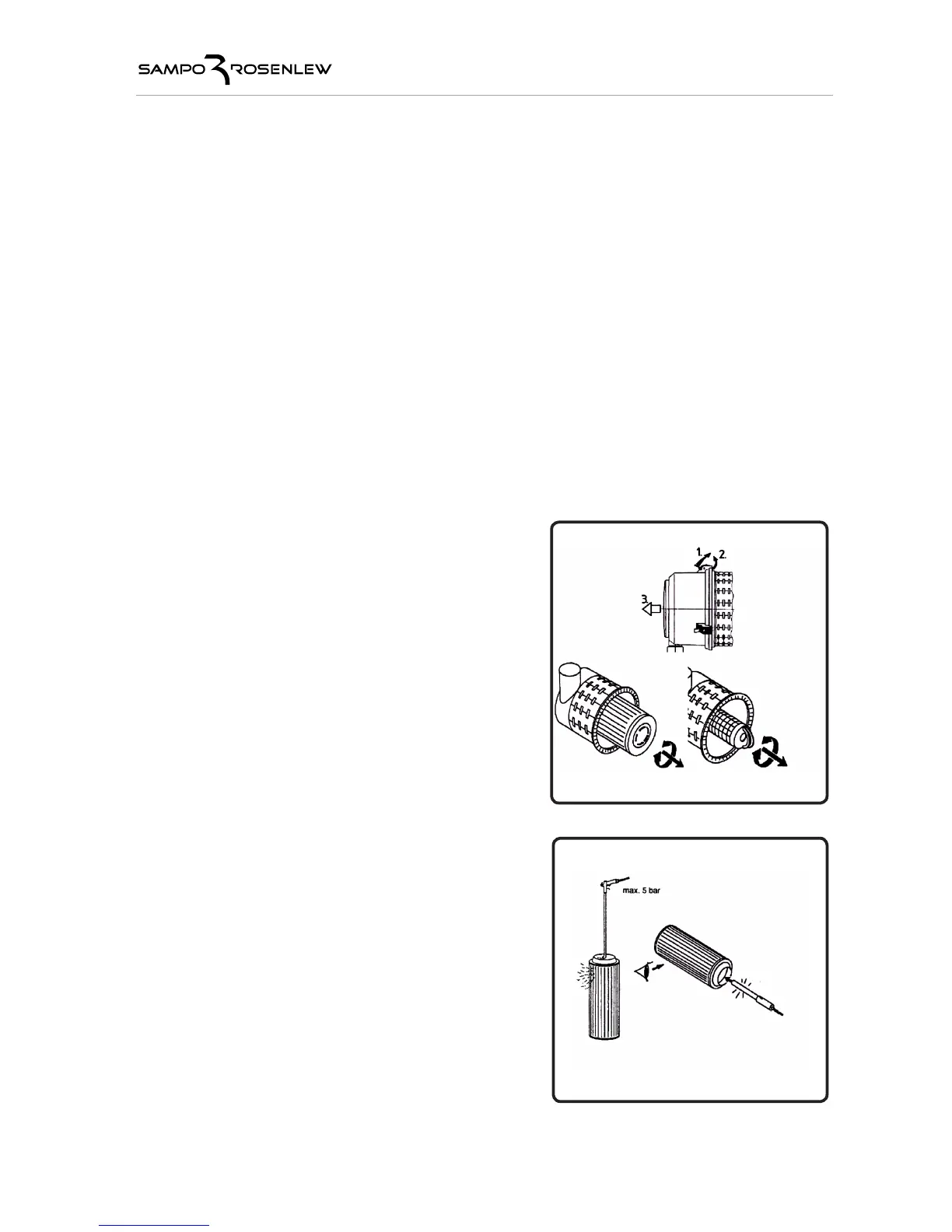

The filter housing is located in the engine compartment. The filter housing cover is fastened with

locking brackets and the filter cartridges are under the cover (fig. 30). The outer filter cartridge

shall be replaced when blockage is indicated on IQAN- monitor or at least every 100 hours. The outer

cartridge can also be cleaned, but no more than five times. Open the locks on the rear filter

cover and twist the cartridge out of the housing. Be careful not to damage the paper. Do not

remove the inner cartridge unless it needs replacing.

The filter protects the suction channel against impu-

rities during service.

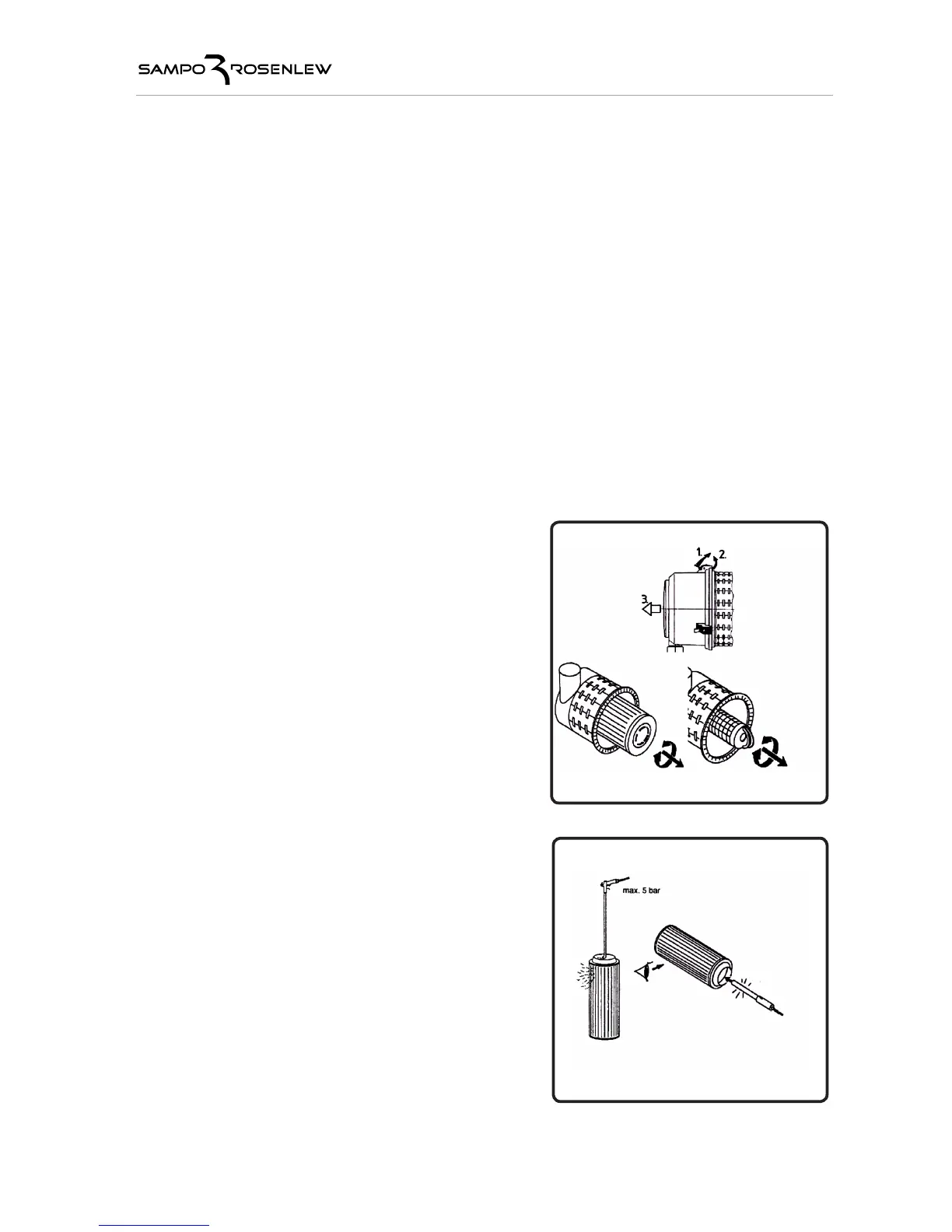

Blow dry compressed air (not over 5 bar) inside the

filter. Great care shall be taken not to damage the

filter cartridge or allow dust inside.

After cleaning, check the condition of the filter. Direct

a strong light from the inside. In case the outer filter

cartridge is broken, it shall be replaced. The

inner filter shall also be replaced as it has become

dirty. Otherwise the inner cartridge is replaced

after five filter services or every other year.

Clean the inside of the filter housing carefully before

removing the inner cartridge. When refitting the

filters, make sure that the gaskets are intact, the

mating surfaces clean and that the filter fits well.

When servicing the filter, check the condition and

attachment of the air hoses and the cleanliness of

the hose in the exhaust fume ejector.

Never run the engine without filters.

2. Checking of battery fluid level

Clean the battery housing carefully. Check that

the battery fluid level is 5-10 mm above the cells.

Make sure the cable lugs are properly tightened.

Remove any oxidisation with hot water. Coat the

cable lugs with copper or aluminium paste.

3. Cleaning of breather on the hydraulic tank

Clean the filter and the surrounding area care-

fully (fig. 32).

Loading...

Loading...