During the first operating month the tightness of the screw connections in the crane,

shafts and joint shall be checked daily.

It is important to tighten the screw connections to the correct torque. The required wrench

sizes and torques:

Screw size

Wrench size

(mm)

Tightening torque for screws

of 8.8 strength class

(Nm)

M 6 10 11

M 8 13 25

M 10 17 47

M 12 19 78

M 14 22 120

M 16 24 180

M 20 30 335

Tightening torques for wheel fixing screws

Front wheels: 600 Nm

Rear wheels: 540 Nm

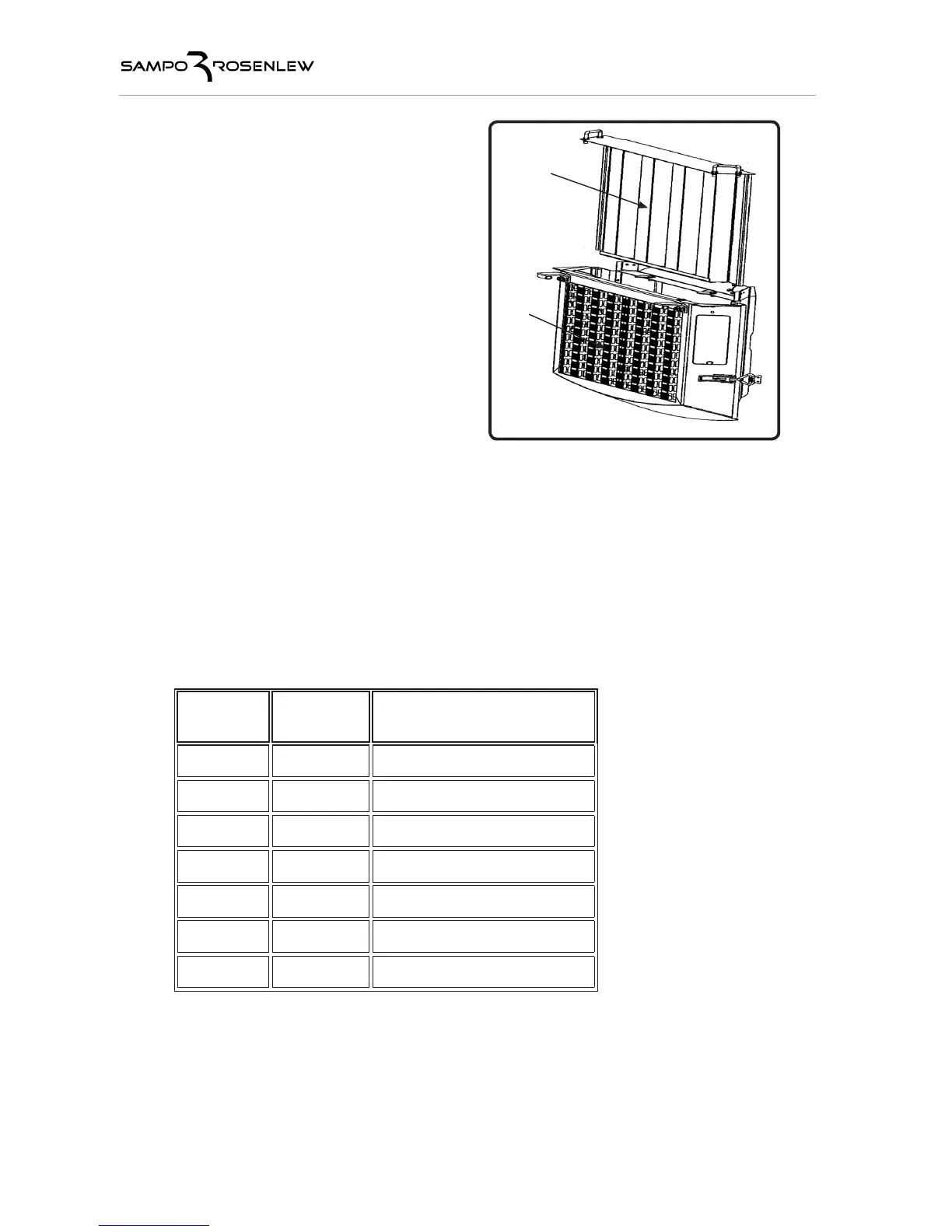

5. Cleaning of radiator grilles

Depending on the operating environment,

the radiator grilles shall be cleaned often

enough to prevent the engine from over-

heating. Clean the rear cog screen and the

removable grille using compressed air or a

brush (fig. 29). When necessary, clean the

oil, engine and air conditioner condensers.

Note! The rear cog and the grilles must not

be covered with the engine running.

6. Checking of tyre air pressure

Check the tyre air pressure and external

condition visually. Use manometer if neces-

sary. The correct air pressure for the 500/60-

26.5 tyres is 3.7 bar, the 600/55-26.5 tyres

4.0 bar, the 540/65R28 tyres 3.2 bar.

Do not exceed the indicated pressures.

7. Checking for leakage

Check for any liquid, fluid and oil leakage.

Loading...

Loading...