EB 8384-2 EN 69

Mounting and start-up

place spacers (11) underneath, if neces-

sary.

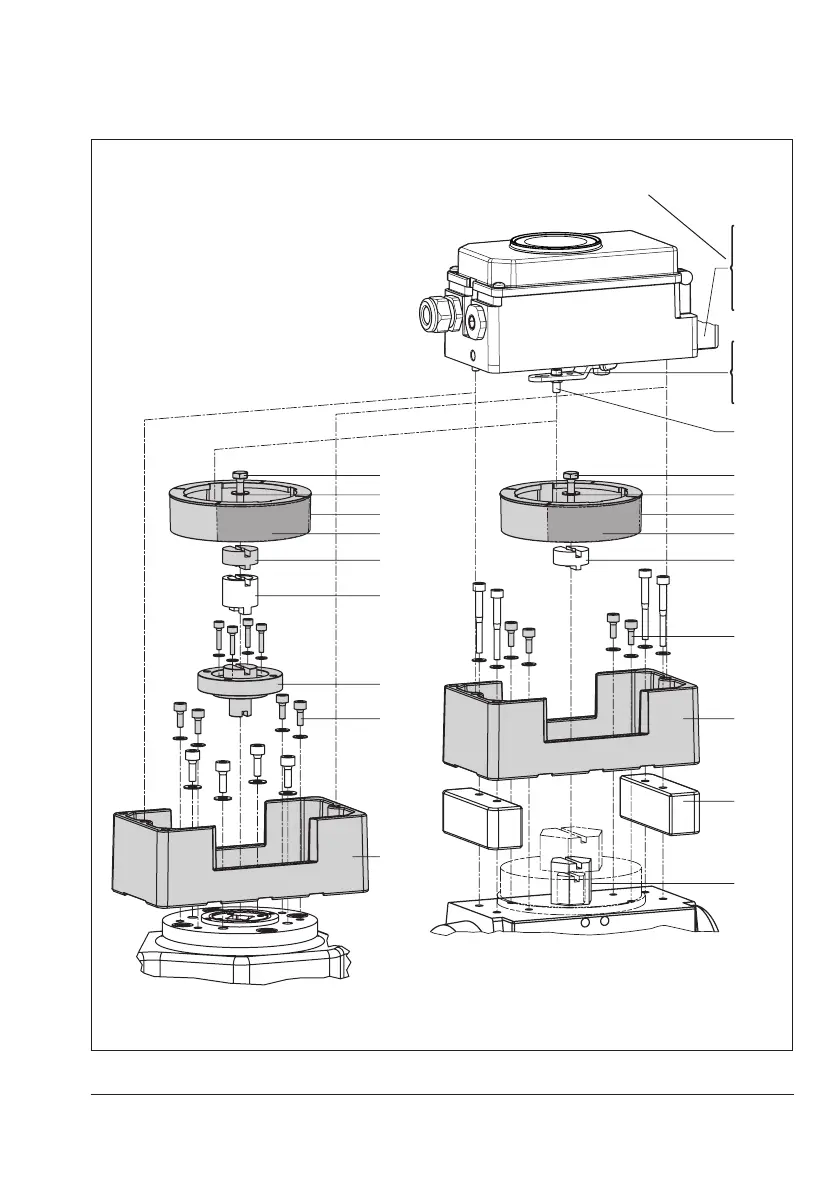

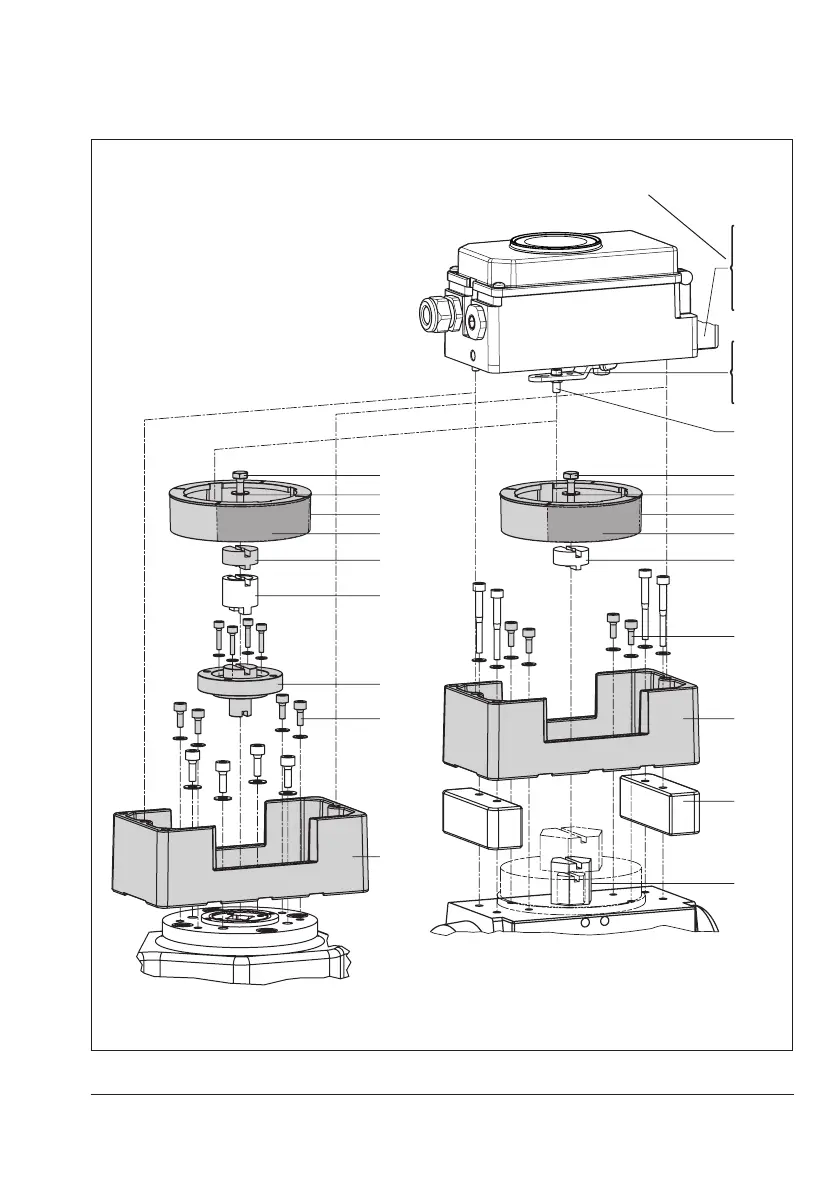

2. For SAMSONType3278andVETEC

S160 Rotary Actuators, fasten the

adapter (5) onto the free end of the shaft

and for VETECR Actuator, place on the

adapter (5.1). For Type3278, VE-

TECS160 and VETECR Actuators, place

on the adapter (3), for VDI/VDE version,

only use the adapter when it is required

due to the actuator size.

3. Stick adhesive label (4.3) onto the cou-

pling in such a manner that the yellow

part of the sticker is visible in the window

of the housing when the valve is OPEN.

Adhesive labels with explanatory sym-

bols are enclosed and can be stuck on

the enclosure, if required.

Actuator turning

counterclockwise

Actuator turning

clockwise

Fig.22: Direction of rotation

6

6.1

7

8

1

1.1

1.2

2

4.1

3

10

11

5

4.3

4

4.2

4.1

3

5.1

5

10.1

10

4.3

4

4.2

1 Lever

1.1 Nut

1.2 Disk spring

2 Follower pin

3 Adapter

4 Coupling wheel

4.1 Screw

4.2 Disk spring

4.3 Adhesive label

5 Actuator shaft or

adapter

5.1 Adapter

6 Connecting plate (only

forG¼)

6.1 Seals

7 Pressure gauge

bracket

8 Pressure gauge

mounting kit

10 Adapter housing

10.1 Screws

11 Spacer

SAMSON Type3278

VETEC S160, VETEC R

Attachment according to VDI/VDE3845

(Sept. 2010) Fixing level 1, AA1 to AA4

size, see section3.8

Use a screw restriction in the signal

pressure output for actuators with

<300cm³volume

Fig.23: Attachment to rotary actuators (heavy-duty version)

Loading...

Loading...