68 EB 8384-2 EN

Mounting and start-up

place spacers (11) underneath, if neces-

sary.

2. For SAMSONType3278andVETEC

S160 Rotary Actuators, fasten the

adapter (5) onto the free end of the shaft

and for VETECR Actuator, place on the

adapter (5.1). For Type3278, VE-

TECS160 and VETECR Actuators, place

on the adapter (3), for VDI/VDE version,

only use the adapter when it is required

due to the actuator size.

3. Stick adhesive label (4.3) onto the cou-

pling in such a manner that the yellow

part of the sticker is visible in the window

of the housing when the valve is OPEN.

Adhesive labels with explanatory sym-

bols are enclosed and can be stuck on

the enclosure, if required.

4. Fasten coupling wheel (4) on the slotted

actuator shaft or adapter (3) using screw

(4.1) and disk spring (4.2).

5. Unscrew the standard follower pin (2)

from the positioner's M lever (1). Attach

thefollowerpin(Ø5mm)includedinthe

mounting kit to pin position 90°.

6. Mount connecting plate (6) for required

G¼connectingthreadorpressure

gauge bracket (7) with pressure gauges

on the positioner, making sure the two

seals (6.1) are seated properly. Dou-

ble-acting springless rotary actuators re-

quiretheuseofareversingamplieron

the connection side of the positioner

housing(seesection5.9).

7. For actuators with a volume of less than

300cm³,screwthescrewrestriction(or-

der no. 1400-6964) into the signal pres-

sure output of the positioner (or the out-

put of the pressure gauge bracket or con-

necting plate).

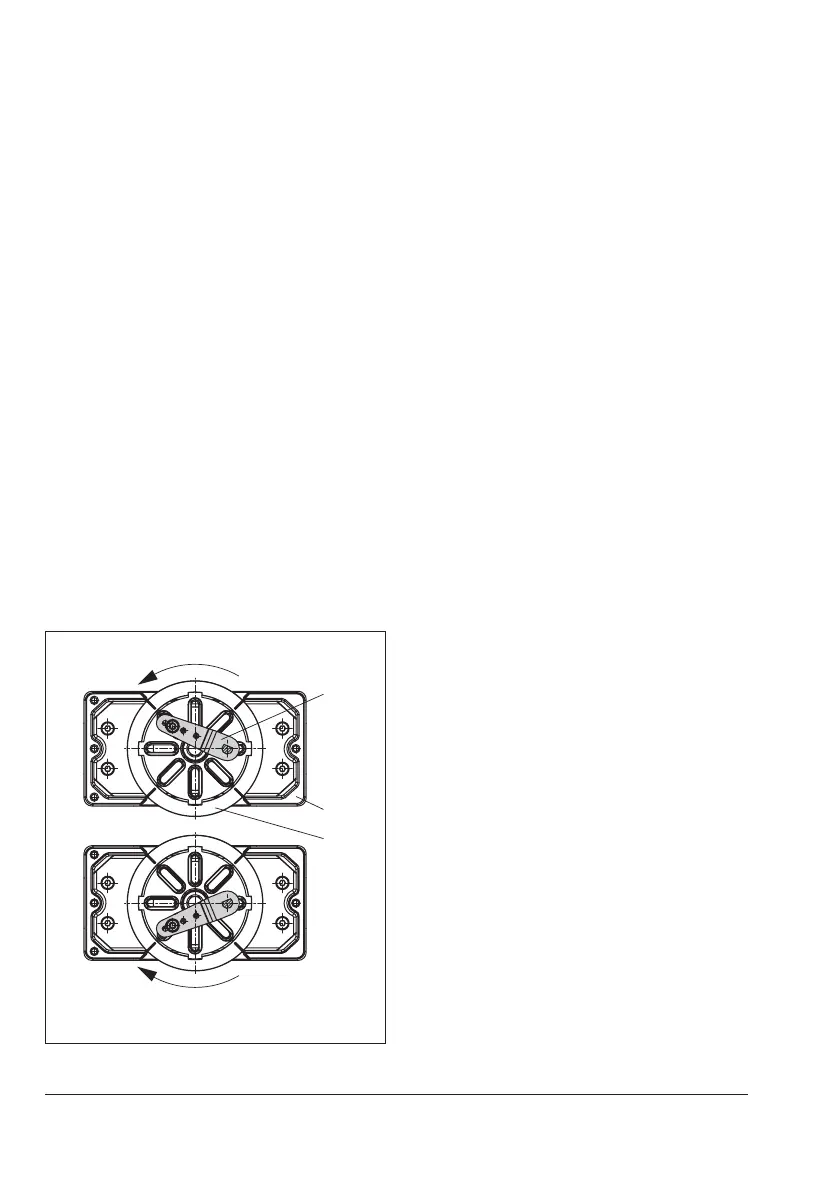

8. Place positioner on housing (10) and

screw it tight. Taking the actuator's direc-

tion of rotation into account, adjust lever

(1) so that it engages in the correct slot

withitsfollowerpin(Fig.22).

1

4

Actuator turning

counterclockwise

Actuator turning

clockwise

Fig.22: Direction of rotation

6

6.1

7

8

1

1.1

1.2

2

4.1

3

10.1

10

11

5

4.3

4

4.2

4.1

3

5.1

5

10.1

10

4.3

4

4.2

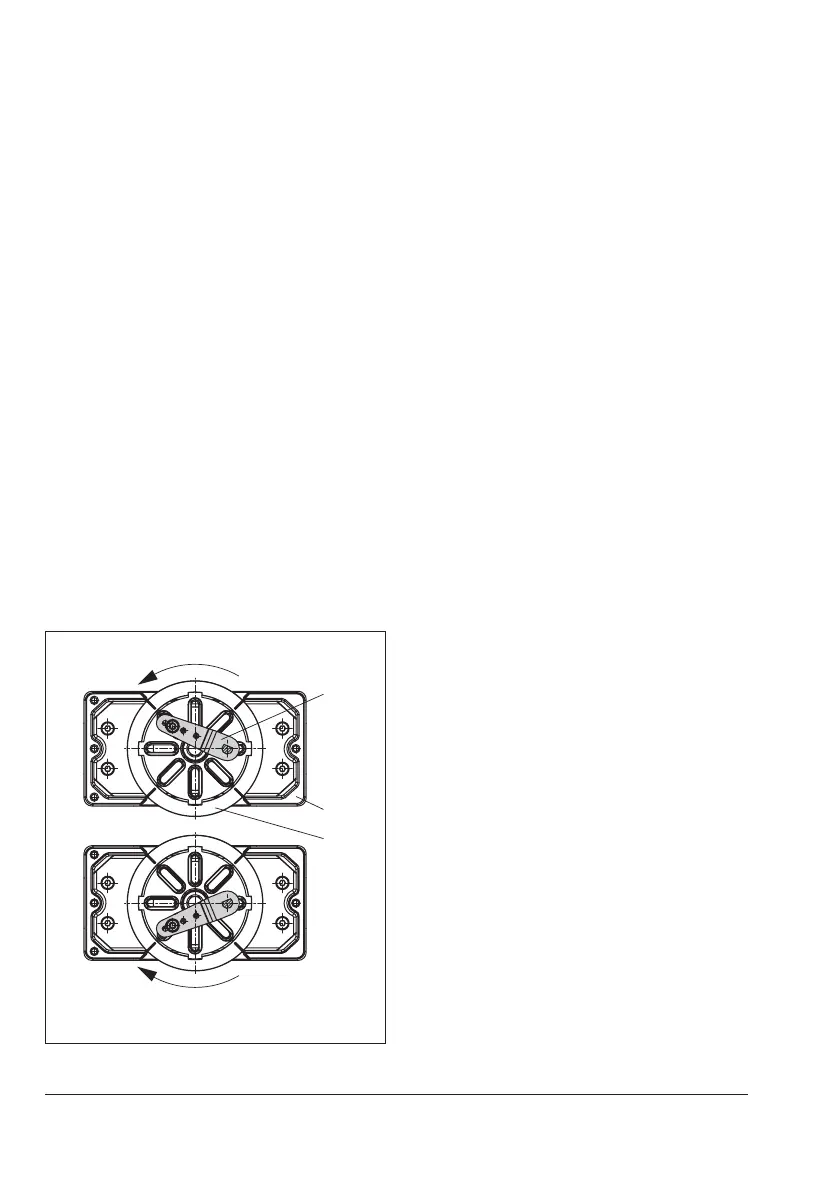

1 Lever

1.1 Nut

1.2 Disk spring

2 Follower pin

3 Adapter

4 Coupling wheel

4.1 Screw

4.2 Disk spring

4.3 Adhesive label

5 Actuator shaft or

adapter

5.1 Adapter

6 Connecting plate (only

forG¼)

6.1 Seals

7 Pressure gauge

bracket

8 Pressure gauge

mounting kit

10 Adapter housing

10.1 Screws

11 Spacer

SAMSON Type3278

VETEC S160, VETEC R

Attachment according to VDI/VDE3845

(Sept. 2010) Fixing level 1, AA1 to AA4

size, see section3.8

Use a screw restriction in the signal

pressure output for actuators with

<300cm³volume

Fig.23: Attachment to rotary actuators (heavy-duty version)

Loading...

Loading...