Operating Instructions and Installation

Samsung Electronics11-20

■ Advantages for installation and maintenance

1. Cost Saving

The graph shows that the unloaded power consumption is 10% of full load power in case of 6 seconds loaded and 6 seconds

unloaded. In each cycle of modulation, the discharge pressure builds up during the loaded cycle, then the discharge pressure

decreases during the unloaded cycle. Similarly, the suction pressure decreases during the loaded cycle and it increases during

the unloaded cycle. The transition time to build up the pressure is a fraction of a second. The average value is around 0.4 sec-

ond.

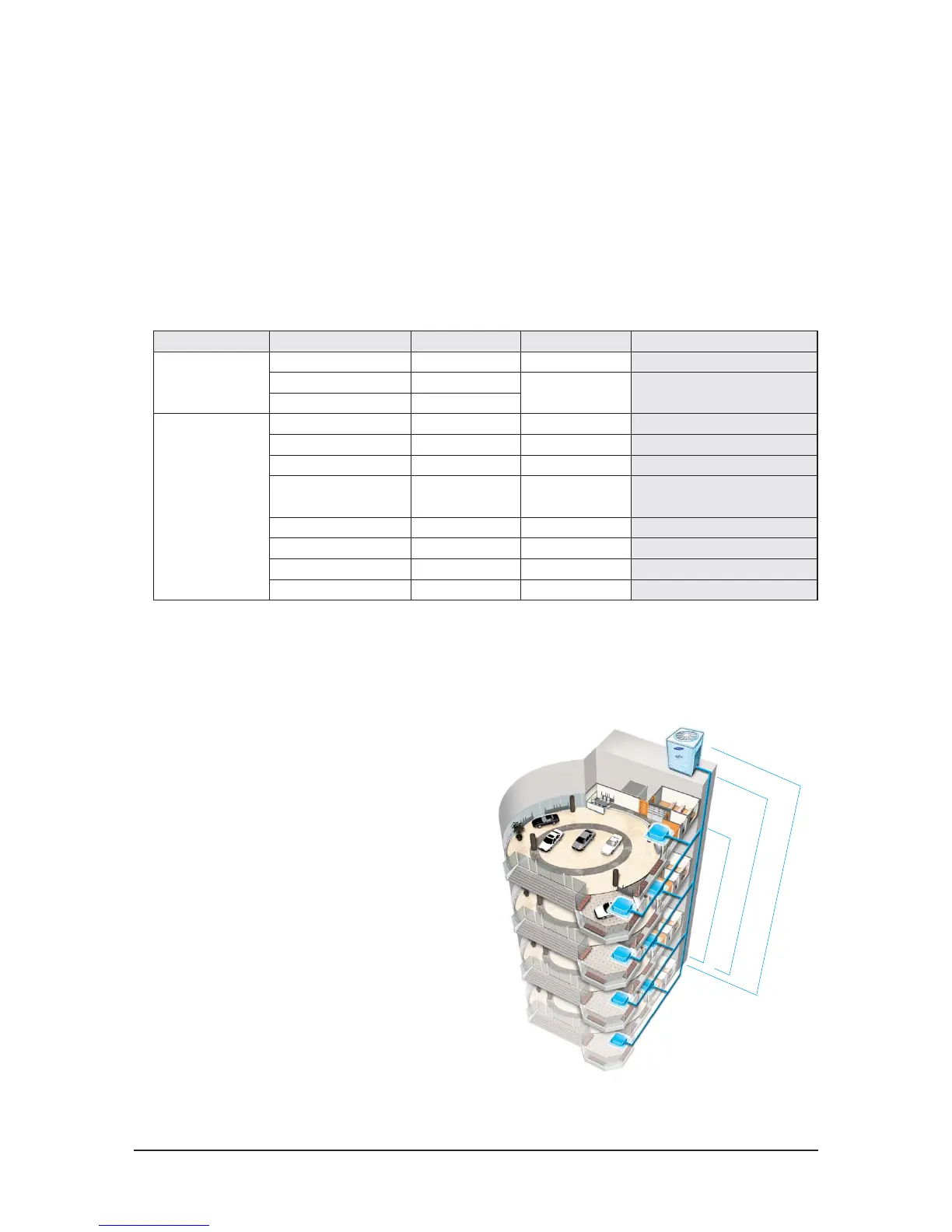

2. Long Pipe Runs for Easy Installation and Application

The refrigerant pipe length between the outdoor and

indoor unit at can be up to 170meters.

• Height between indoor and outdoor unit can be

50meters.

• The value is calculated from the case where the

outdoor unit is installed above the indoor unit. If the

outdoor unit is located underneath the indoor unit,

the level difference would be a maximum of 40meters.

• Equivalent piping length between outdoor and

indoor units ≤ 190meter(DVM Plus2)

• The distance from the first refnet joint to the

indoor unit ≤ 45meters (DVM Plus2)

15m(Height between indoor units)

50m

(Height between indoor and outdoor unit)

170m(Max. piping length)

* Total pipe length of DVM Plus2 are 300m respectively.

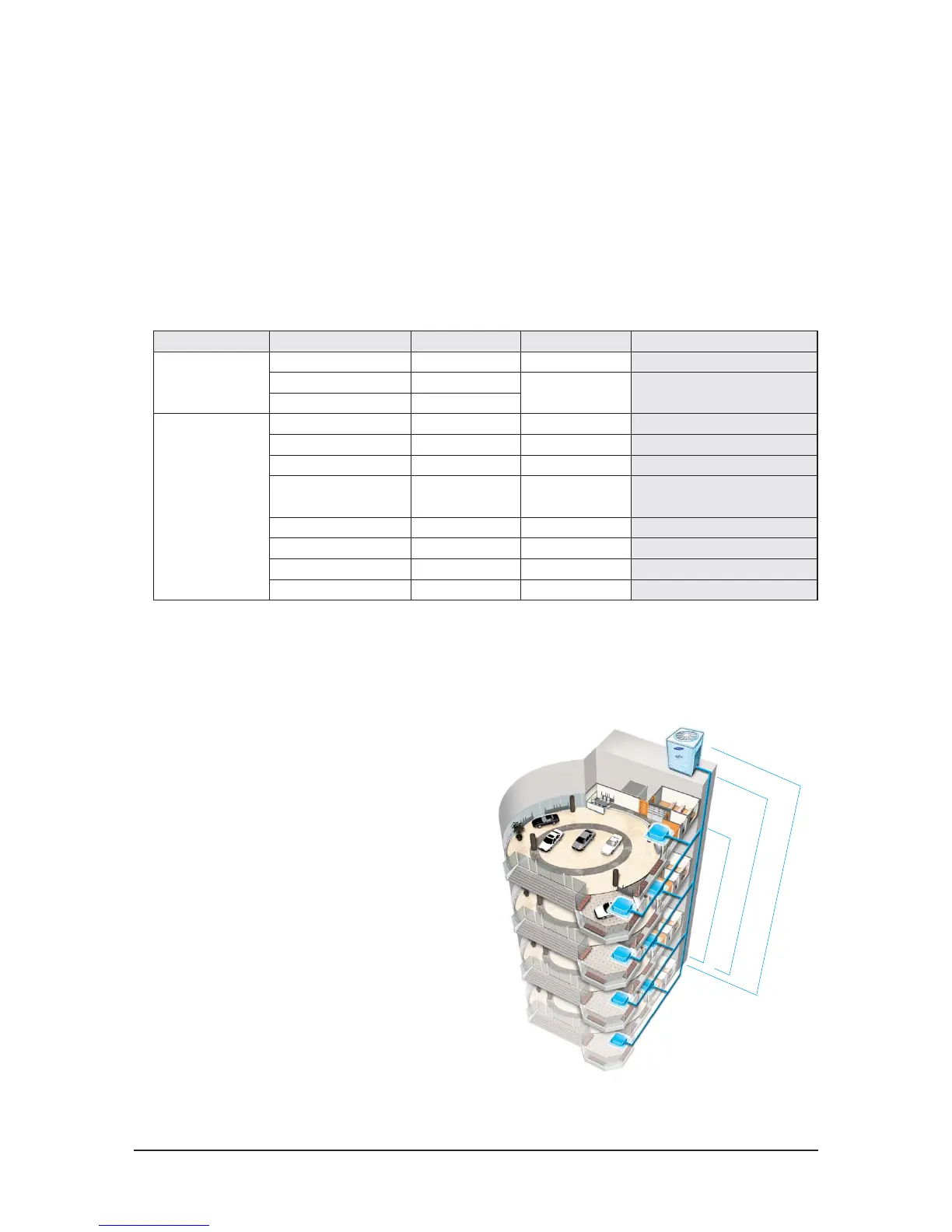

Division

Equipment

Piping

Duct-install

Grand

Power consumption

Monthly consumption

Annual consumption

(6 months in a year)

1 year rate

3 year rate

5 year rate

Comparison

Initial cost

(US$)

Running cost

(US$)

Chiller

25,558

5,111

17/m

2

43,419

43kW X 1.0

15,695kWh

94,170kWh

6,780

20,340

33,900

121%

Unitary

27,500

17/m

2

40,250

52.5kW X 1.0

19,162kWh

114,972kWh

8,277

24,833

41,389

148%

DVM

29,812

17/m

2

42,562

44.2kWx0.8(Variable compressor)

12,906kWh

77,436kWh

5,575

16,726

27,877

100%

• Heat loads : 90,000 kcal/h in Korea • Total area : 750m

2

• Running : Every 3 months in summer and winter

Compare DVM technology with conventional systems

Loading...

Loading...