Service Manual

Alignment & Adjustments

4-24

Samsung Electronics

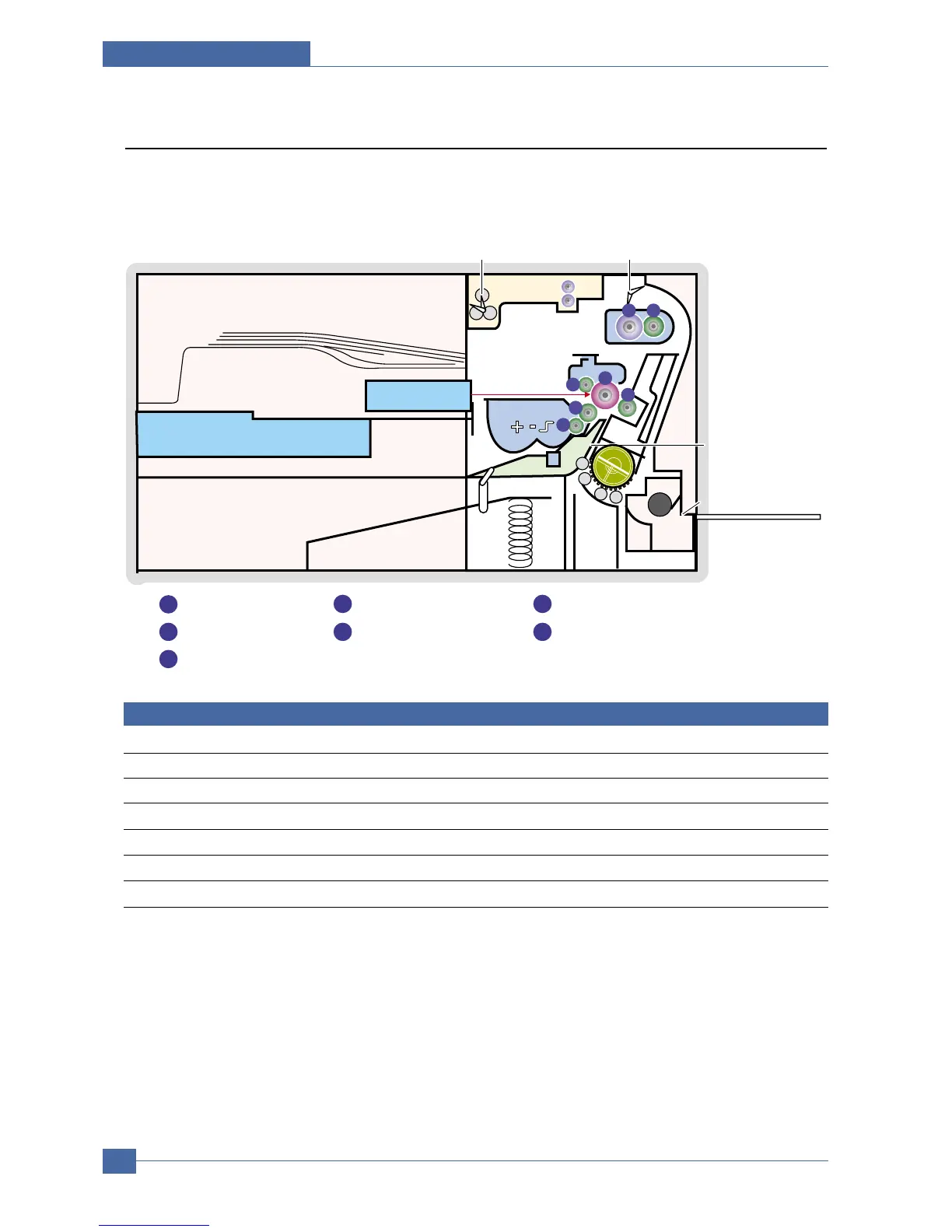

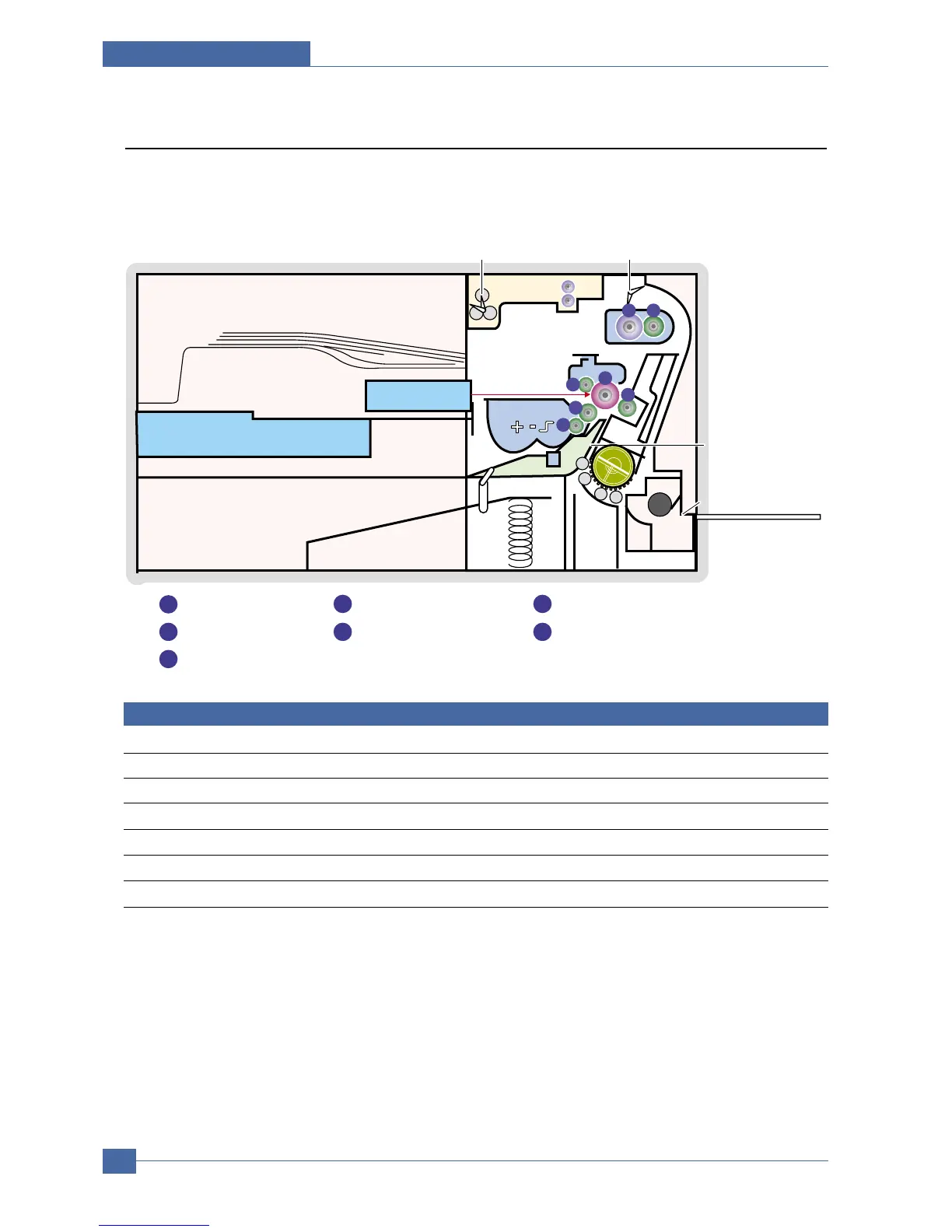

4.6 Abnormal Image Printing and Defective Roller

If a mark or other printing defect occurs at regular intervals down the page it may be caused by a damaged or

contaminated roller. Measure the repetition interval and refer to the table below to identify the roller concerned.

No Roller Abnormal image period Kind of abnormal image

1 OPC Drum 94.30mm White spot, Block spot

2 Charge Roller 38.30mm Black spot

3 Supply Roller 43.80mm Horizontal density band

4 Develop Roller 54.30mm Horizontal density band

5 Transfer Roller 56.60mm Black side contamination/transfer fault

6 Heat Roller 83.60mm Black spot and fuser ghost

7 Pressure Roller 91.00mm Black side contamination

SMPSSMPS

LIULIU

Main Board+Engine BoardMain Board+Engine BoardMain Board+Engine Board

EMPTYEMPTY SENSOR(MPF) SENSOR(MPF)EMPTY SENSOR(MPF)

FEED SENSOR

FEED SENSORFEED SENSOR

EMPTY

EMPTY SEN SENEMPTY SEN

TONER UNITONER UNITTONER UNIT

FTL

FTLFTL

OPC UNIT

OPC UNITOPC UNIT

OPC UNIT

OPC UNITFUSER

MPF

EXITEXIT SENSOR SENSOREXIT SENSOREXITEXIT SENSOR SENSORBIN FULL SENSOR

Loading...

Loading...