Section 3: Operation and Configuration

Page 3-10 CG4 Series Operator Manual

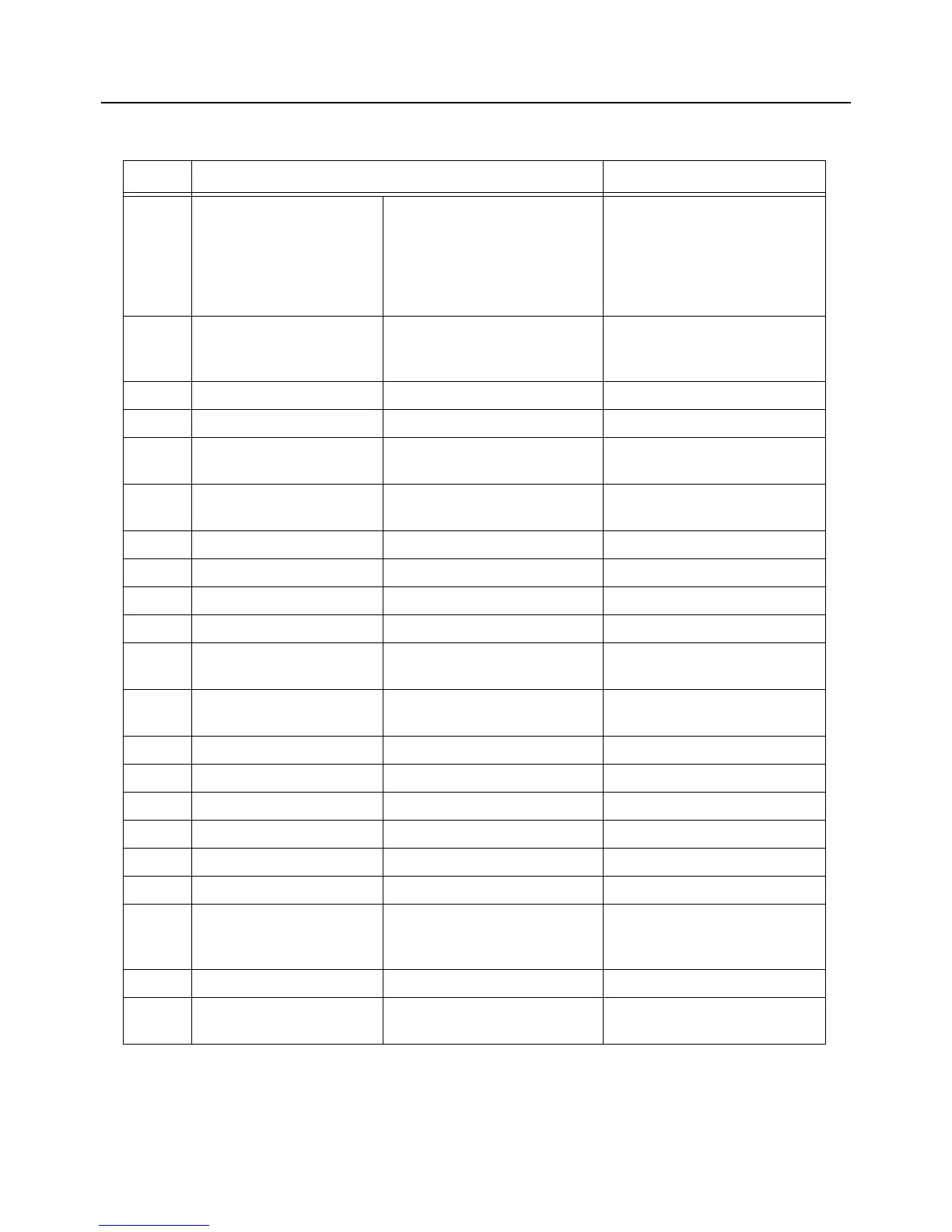

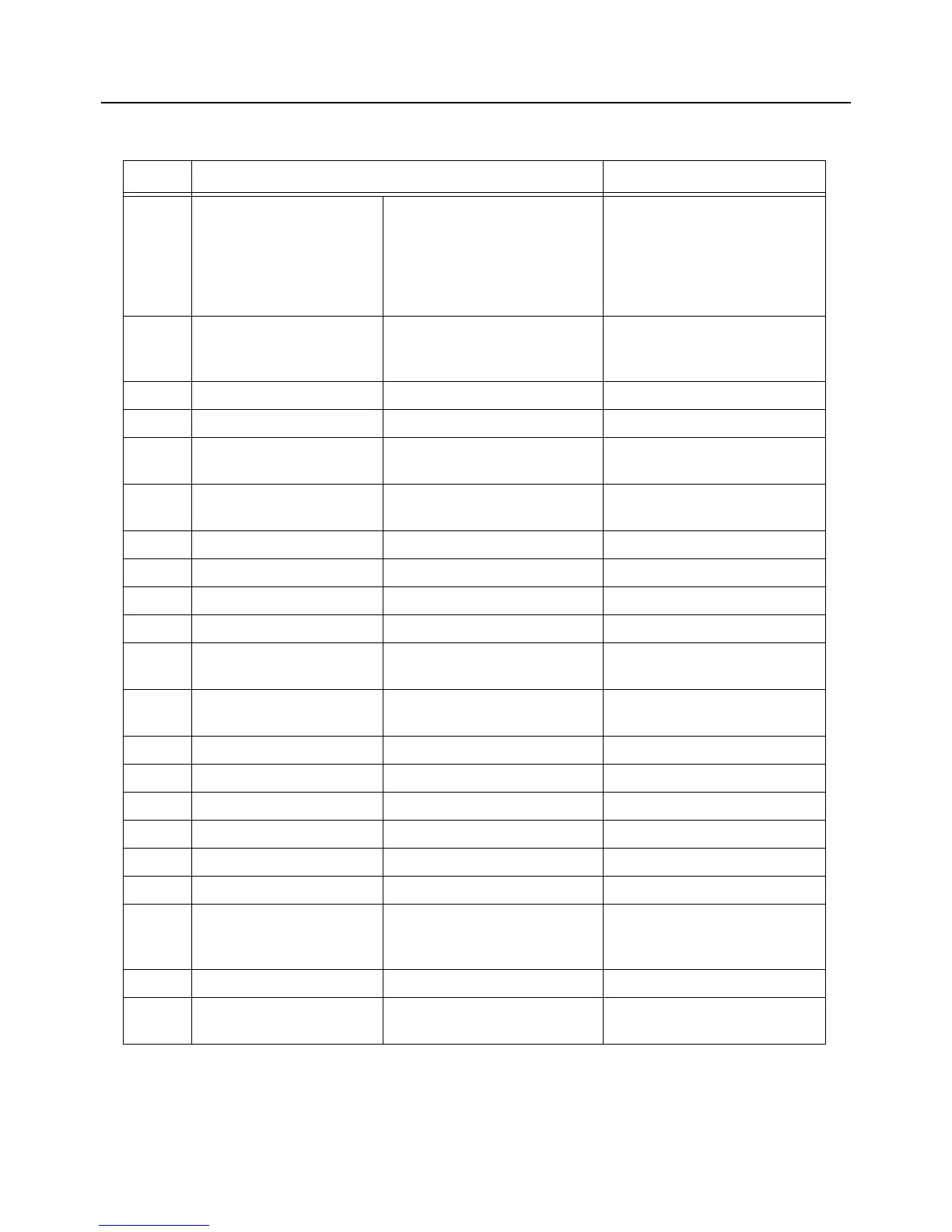

3.4 FACTORY TEST PRINT MODE (cont’d)

Second print-out (Settings)

Third print-out (Interface)

This interface information is similar to the third print-out in user test print mode. Refer to Section 3.3.1 Output

Data of the User Test Print for details.

No. Print Item Contents of the print data

1 Model Printer model name CG408TT(*), CG412TT(*)

CG408DT, CG412DT

*: “T” is printed for thermal

transfer print.

“D” is printed for direct

thermal print.

2 Offset Base reference correction

(Vertical and horizontal

directions)

(H)±300 (V)±300 DOT

3 Pitch Offset Pitch offset value ±099 DOT

4 Cut Offset Cut position correction value ±099 DOT

5 Peel Offset Peel off position correction

value

±099 DOT

6 Tear Off Offset Tear off position correction

value

±099 DOT

7 Label Size Label size (Pitch/Width) (P)**** x (W)*** DOT

8 Print Speed Print speed 50mm/s, 75mm/s, 100mm/s

9 Print Darkness Print darkness 1A~5A

10 Sensor Type Sensor type Gap / I-Mark / None

11 Sensor Level Low Average minimum value of

pitch sensor

*.* V

12 Sensor Level High Average maximum value of

pitch sensor

*.* V

13 Sensor Slice Level Pitch sensor slice level *.* V

14 Paper End Search Paper end detection method TAG/ ROLL

15 Zero Slash Zero slash ON/ OFF

16 Proportional Pitch Proportional pitch ON/ OFF

17 Buzzer Buzzer ON/OFF

18 Initial Feed Initial feed ON/ OFF

19 Operation mode Operation mode CUT/ NONE SEPA/

TEAR OFF/ DISPENSER/

CONTINUOUS

20 Option waiting time Option waiting time 500 to 20000 ms

21 Protocol-codes Protocol code setting value

(Standard / Nonstandard)

Nonstandard/ Standard

Loading...

Loading...