Since the engine may be running during filter re-

newal, fuel spillages may occur. Use a suitable

container. Used fuel must be disposed of as spec-

ified in national and international law.

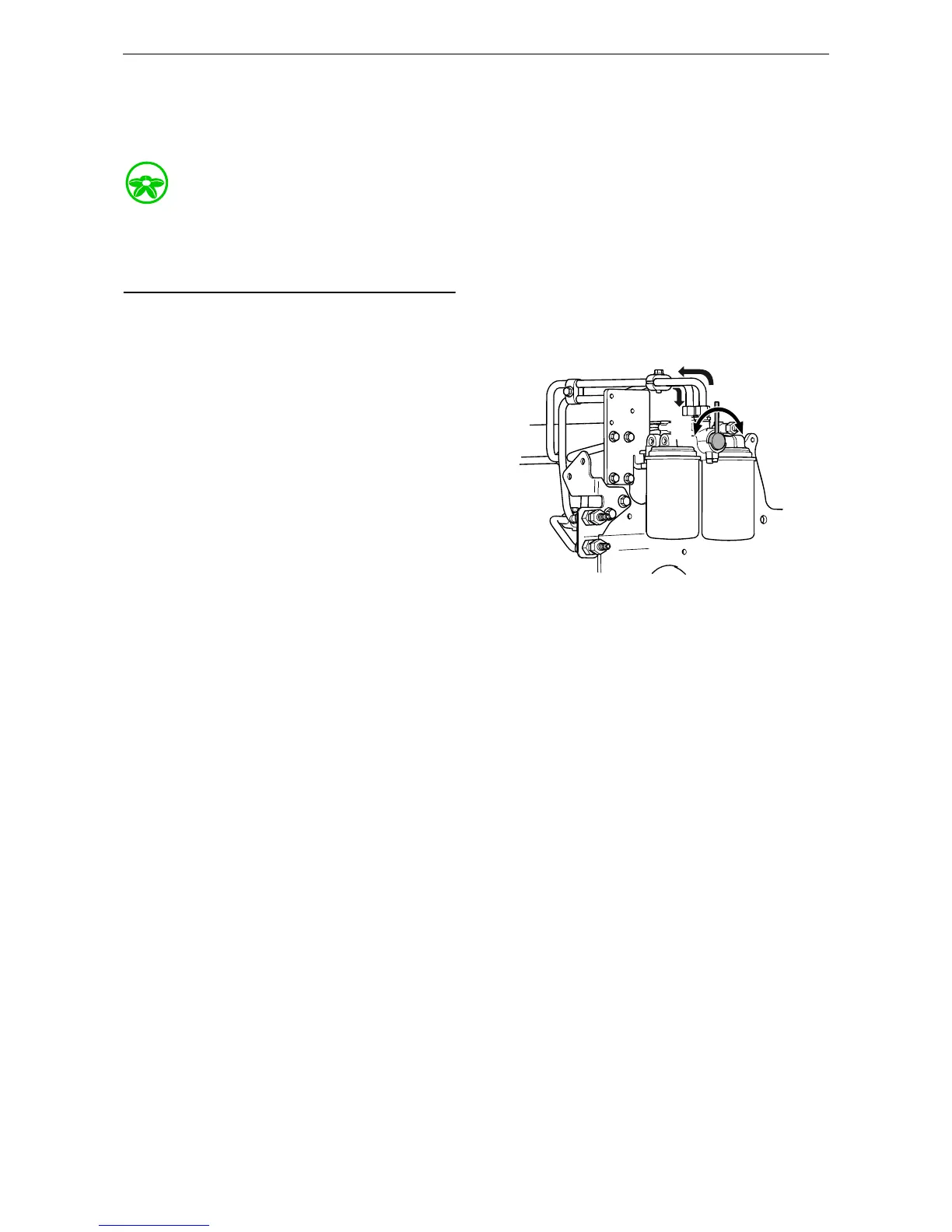

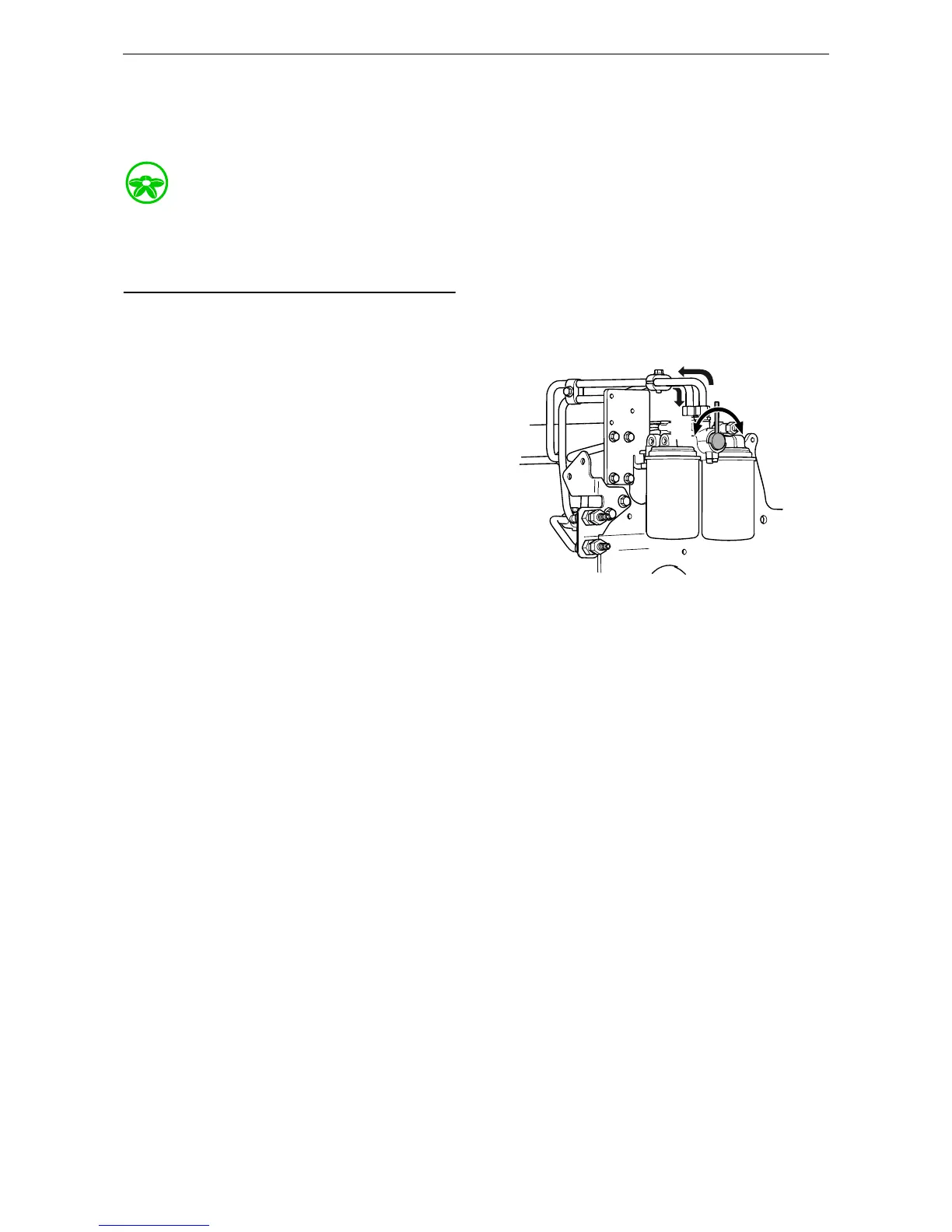

During operation, the rotary control should point

90° towards the filter being used.

1. Turn the rotary control 90° to the right so that

it points towards filter B. The fuel then flows

through the filter.

2. Connect a transparent plastic hose to the

bleed nipple located above filter A. Place the

other end in a container with a capacity of at

least 3 litres (1 US gallon).

3. Open the bleed nipple on side A. The remain-

ing pressure is released.

4. Clean the exterior of the filter with a cloth.

5. Unscrew the filter.

6. Apply oil to the gasket on the new filter.

7. Screw the fuel filter into place by hand until

it makes contact. Turn screw a further half

turn by hand.

8. Turn the rotary control 90° to the left so that

the rotary control points straight up. Both fil-

ters now run simultaneously.

9. When fuel without air bubbles comes out:

Close the bleed nipple. Because the engine is

running, a lot of fuel will come through the

hose.

10. Turn the rotary control 90° to the left so that

the rotary control points towards filter A. Fil-

ter B can now be renewed in the same way as

filter A.

Loading...

Loading...