15

2021-04-12 / V1.1

Contactors CP Series – Installation and Maintenance Instructions

Installation

8. Installation

8.1 Mounting positions

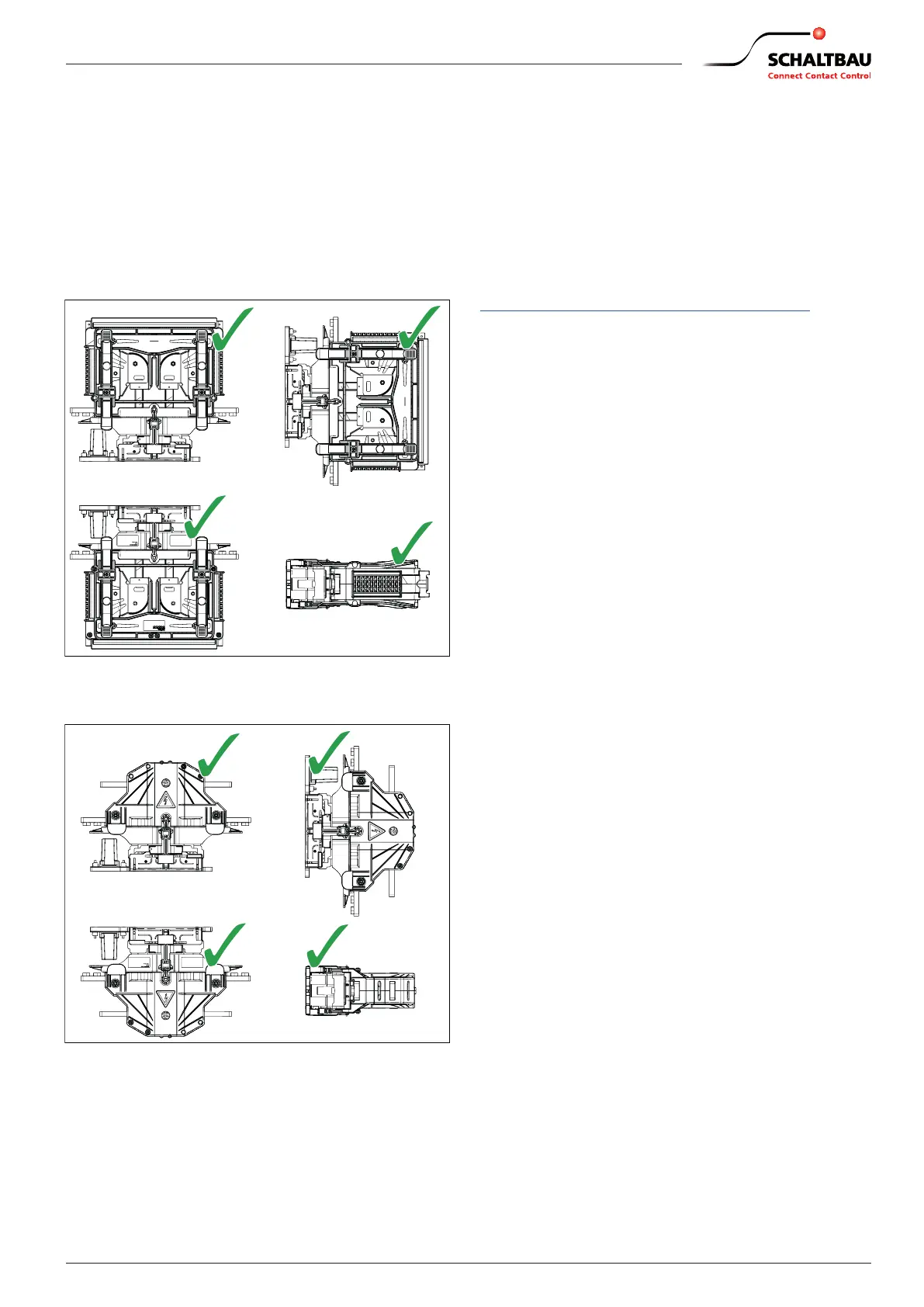

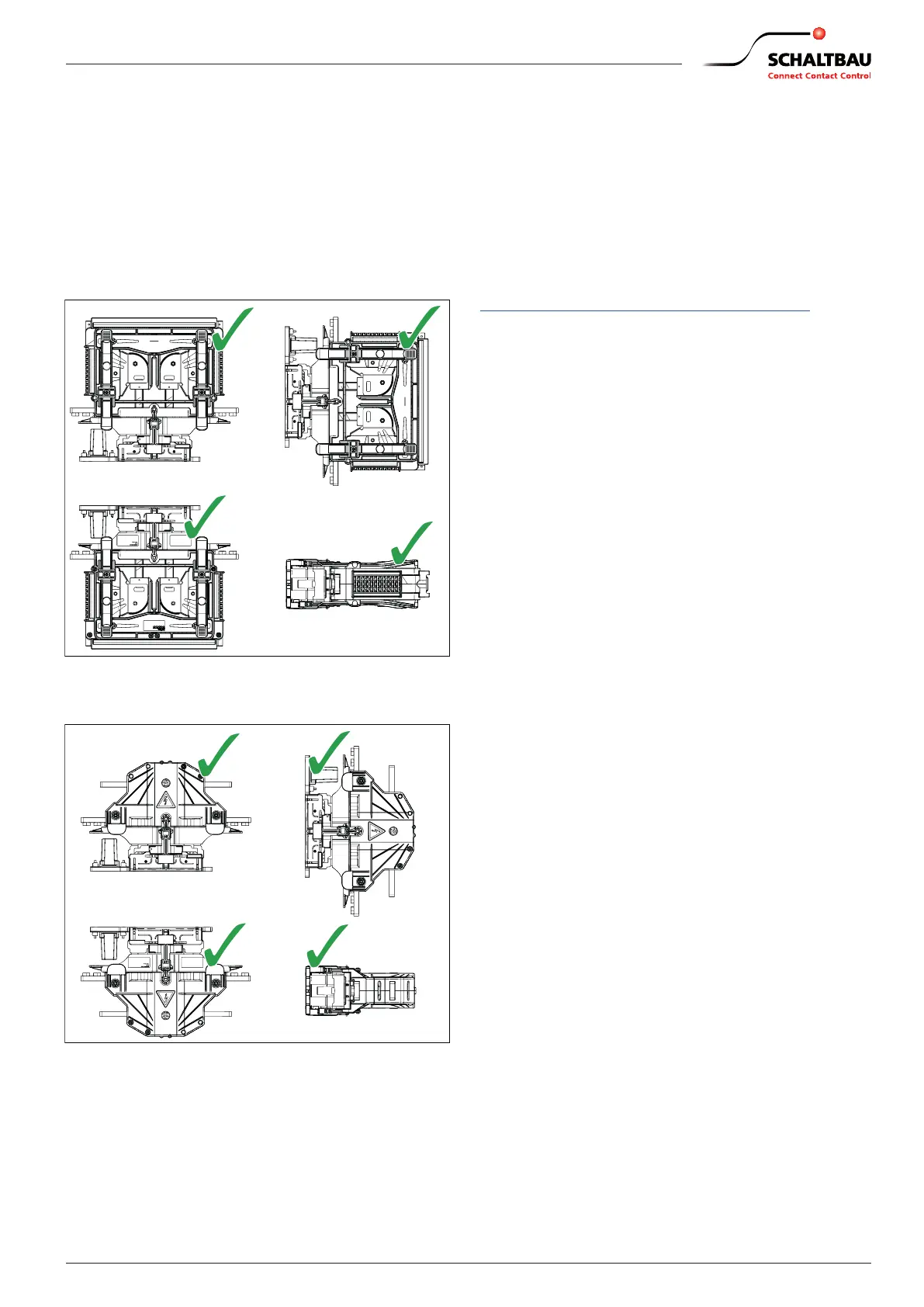

The contactors are designed for horizontal or vertical

mounting. Examples of permissible mounting positions

are presented in Fig. 7 and Fig. 8. Even mounting posi-

tions suspended over head are permitted.

Fig. 7: Examples of permissible mounting positions - NO/NC

devices

Fig. 8: Examples of permissible mounting positions - CO

devices

8.1.1 Dimensions/interfaces and further

technical specications

The dimensions and other technical specications are

given in the respective data sheets or can be found in

our C40 catalogue. The catalogue is available under:

https://www.schaltbau.com/en/media-library/

8.2 Mechanical installation

8.2.1 Preparatory measures

X

A suitable mounting frame or plate with 4 mount-

ing holes must be provided for fastening of the

contactor. See Fig. 9 and Fig. 10.

X

The mounting frame or plate must be solid enough

to carry the weight of the device under shock and

vibration conditions.

X

The mounting holes can be either:

- threaded holes (for threaded screws)

- or through holes (for threaded screws and nuts)

X

Fastening of the contactors on the mounting plate

is performed using four M8 mounting screws.

- The length of the mounting screws must be de-

termined dependent on the structural circum-

stances.

- To secure the mounting screws so that they

do not come loose, appropriate screw locking

elements must be provided. Schaltbau recom-

mends using Schnorr washers (or similar).

- The mounting screws (and if applicable the

nuts) must be strength class 8.8 or higher.

X

The mounting screws must be tightened to the

specied torque, which depends on the strength

class (min. 8.8) of the screws/nuts used.

Loading...

Loading...