38

2021-04-12 / V1.1

Maintenance

Contactors CP Series – Installation and Maintenance Instructions

Installing the pre-charging contactor

(CPP)

With 1,200 A and 2,000 A devices

X

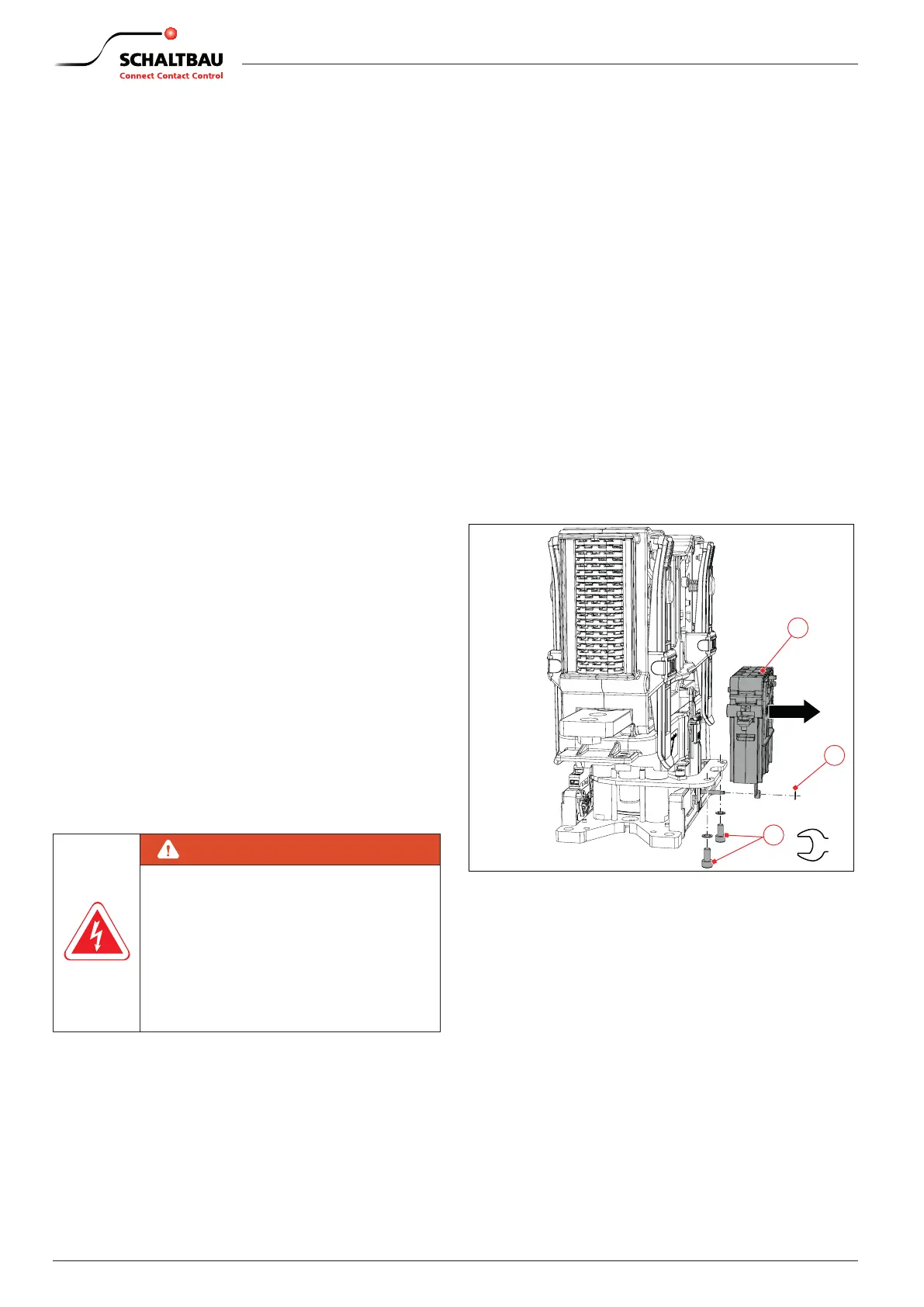

Position the new CPP (1) on the base plate of the

main contactor.

X

Screw in the 2 xing screws (2).

X

Tighten the 2 xing screws (2) to a torque of 4Nm.

X

Reconnect the cables to the CPP (1), see “8.4.8

Connecting the optional pre-charging contactor

(CPP)”.

With 600 A devices

X

Ensure that the contact surfaces on the mount-

ing plate (3) and the bottom of the CPP (1) are

free from dirt and other contamination (e.g. metal

chips).

X

Position the new CCP (1) on the mounting plate (3)

X

Screw the CCP (1) on the mounting ange to the

mounting plate (3) using 4 mounting screws M5

including washers (2).

X

Tighten the mounting screws to the specied

torque, which depends on the strength class (min.

8.8) of the screws/nuts used.

X

Reconnect the cables to the CPP (1), see “8.4.8

Connecting the optional pre-charging contactor

(CPP)”.

9.3.7 Replacing the optional high-

voltage discharging contact (CPD)

Safety

DANGER

Before beginning any work on the con-

tactors, make sure that

X

there is no voltage present,

X

all safety regulations are fully ob-

served.

X

Refer also to section „Dangers and

security measures“ on page 6.

Spare parts required

High-voltage discharging contact (CPD), see chapter

“10. Spare parts”

Tools required

- Set of torx bits

- Hexagon socket wrench set

- Circlip pliers (external)

- Torque wrench

Preliminaries

The cables at the high-voltage discharging contact

(CPD) are disconnected, see “9.3.7 Replacing the op-

tional high-voltage discharging contact (CPD)”.

Removing the high-voltage discharging

contact (CPD)

X

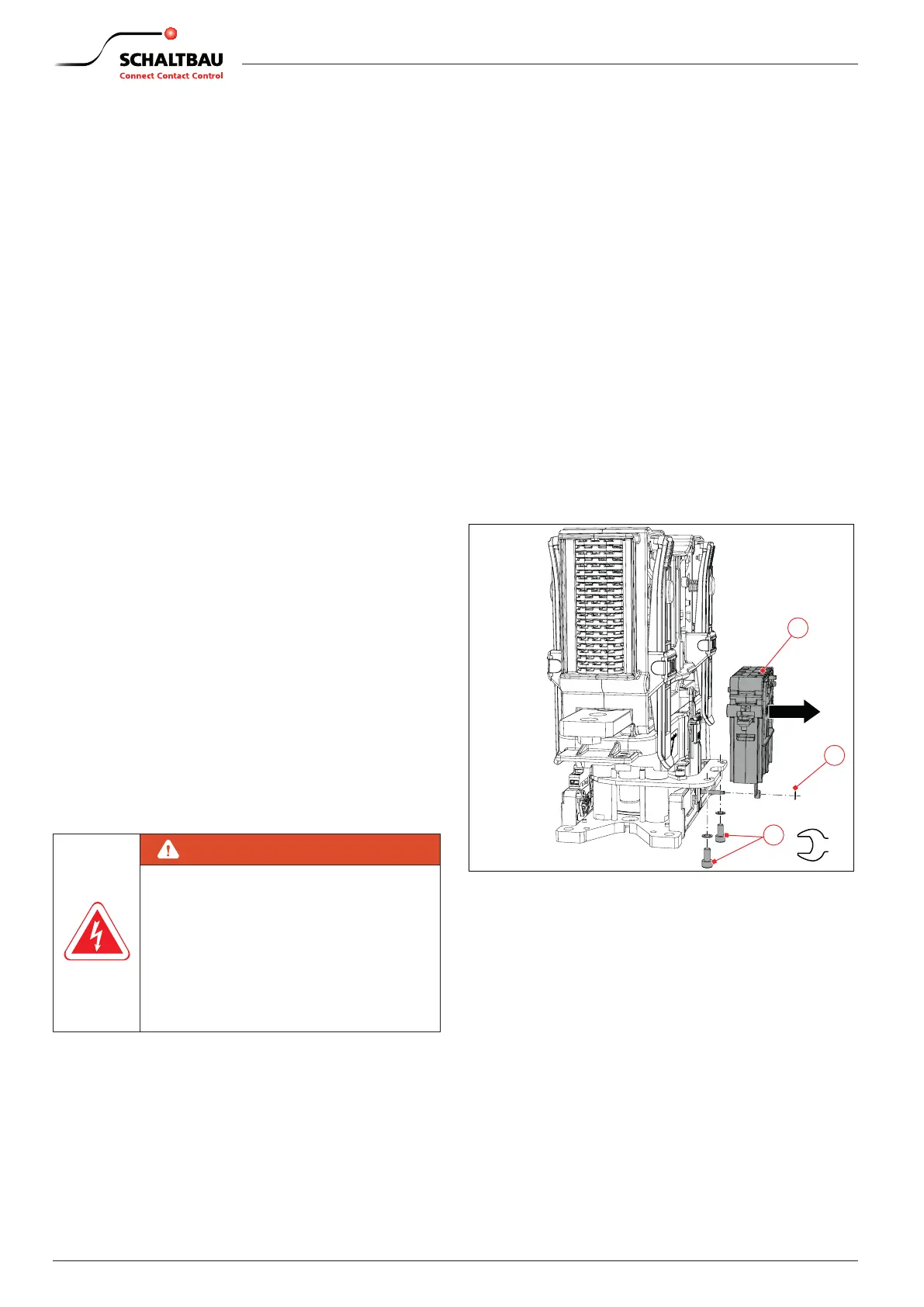

Remove the shaft circlip (1).

X

Unscrew and remove the two screws (2) including

washers.

X

Remove the CPD (3).

2

1

3

3

Nm

Fig. 43: NO/NC contactors – remove the high-voltage

discharging contact (CPD)

Loading...

Loading...