34

2021-04-12 / V1.1

Maintenance

Contactors CP Series – Installation and Maintenance Instructions

X

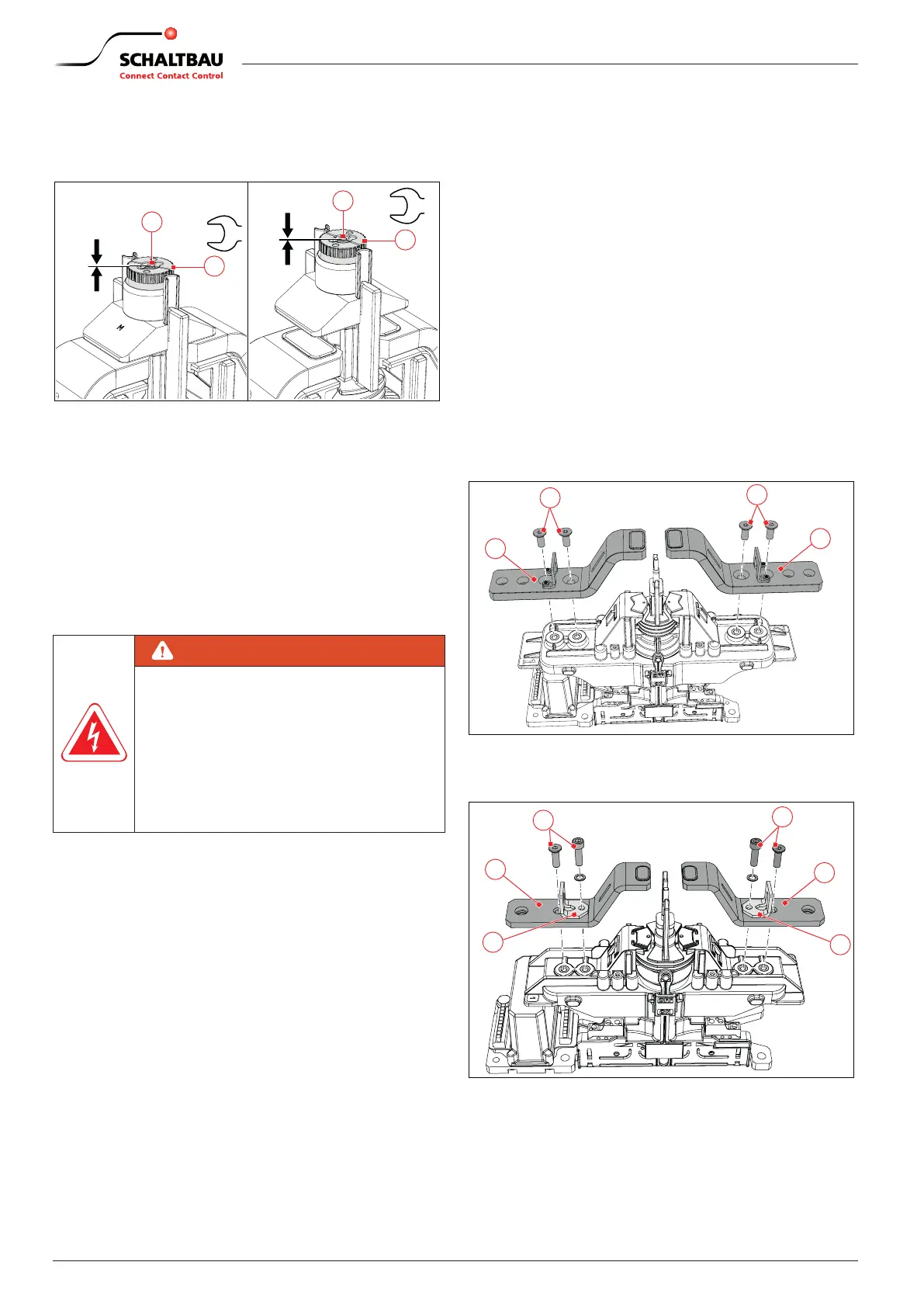

Screw the spring sleeve (1) by hand onto the

thread of the switch rod (5) until it is ush with the

switch rod. Tightening torque: 3 Nm.

5

3

Nm

1

5

3

Nm

1

NO

NC

Fig. 34: NO/NC contactors – spring sleeve (1) and switch rod

(5) must be ush

9.3.4 Replacing the xed contacts

The xed contacts only needs to be replaced for devic-

es with arc chamber, but not for devices with load-free

breaking capacity. The cover of devices with load-free

breaking capacity must not be removed.

Safety

DANGER

Before beginning any work on the contac-

tors, make sure that

X

there is no voltage present,

X

all safety regulations are fully ob-

served.

X

Refer also to section „Dangers and

security measures“ on page 6.

Spare parts required

- Set of main contacts, see chapter „10. Spare parts“.

Tools required

- Hexagon socket wrench set

- Set of torx bits

- Socket wrench set

- Open-end wrench set

- Torque wrench

Preliminaries

- The connecting cables or busbars of the main con-

tacts are disconnected, see “8.4.6 Connecting the

main contacts”.

- For contactors with arc chambers: The arc chamber

unit is removed, see “9.3.1 Replacing the complete

arc chamber unit”.

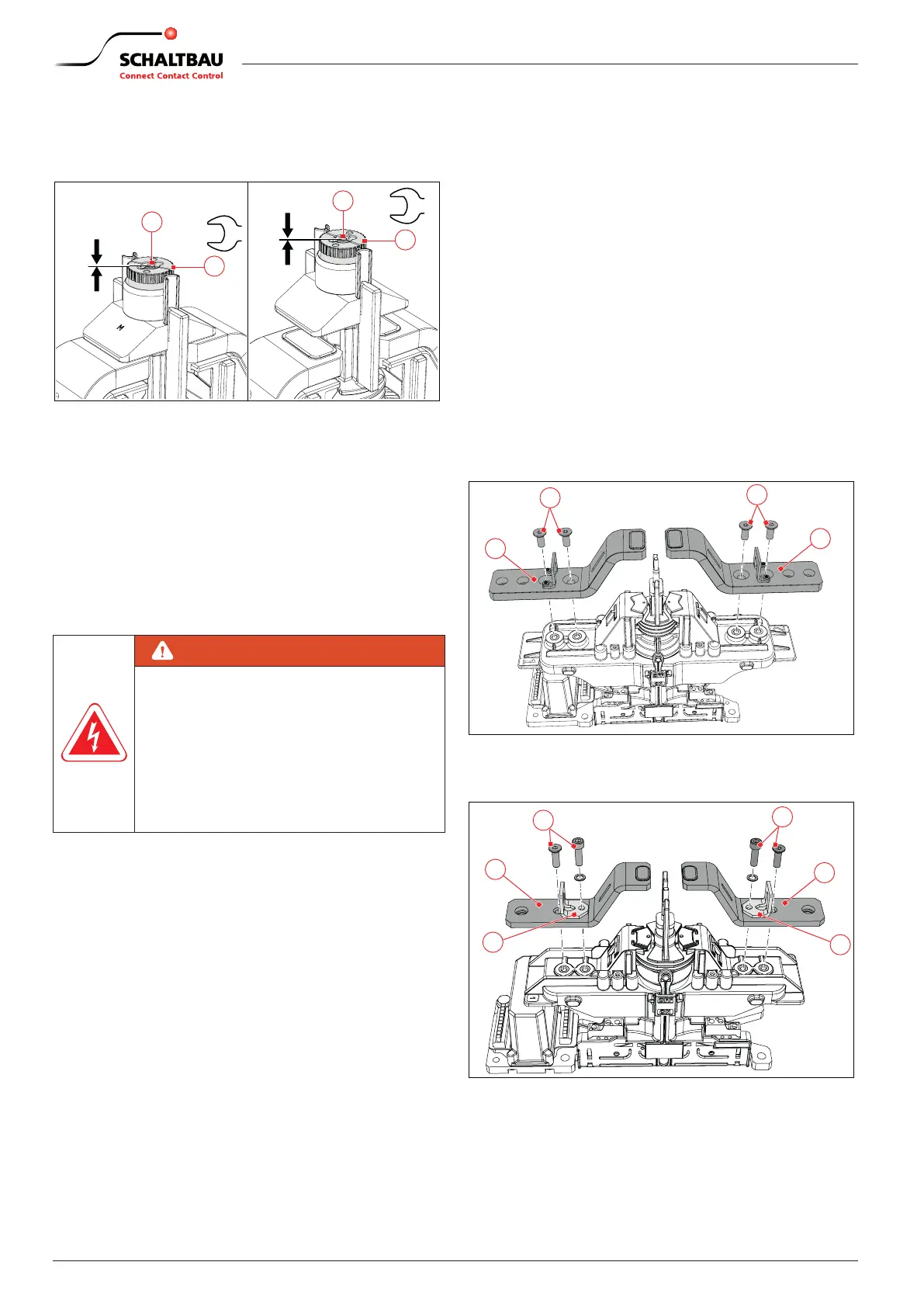

Removing the xed contacts

NO/NC contactors with arc chambers:

X

Unscrew and remove the two screws (1) on both

sides.

X

Remove the xed contacts (2).

X

For 600 A devices, additionally remove the bracket

(3).

1

2

2

1

Fig. 35: 1,200 A and 2,000 A NO/NC contactors with arc cham-

bers – remove the xed contacts

1

2

2

1

3

3

Fig. 36: 600 A NO/NC contactors with arc chambers – remove

the xed contacts

Loading...

Loading...