19

2021-04-12 / V1.1

Contactors CP Series – Installation and Maintenance Instructions

Installation

8.3.2 Installation of the CPP with 600A

devices

Preparatory measures

X

With 600 A devices, 4 mounting holes at the

mounting frame or plate must be provided to fas-

ten the CPP.

X

The mounting holes can be either:

- threaded holes (for threaded screws)

- or through holes (for threaded screws and nuts)

X

Fastening of the CPP on the mounting frame or

plate is performed using four M5 mounting screws.

- The length of the mounting screws must be de-

termined dependent on the structural circum-

stances.

- To secure the mounting screws so that they

do not come loose, appropriate screw locking

elements must be provided. Schaltbau recom-

mends using Schnorr washers (or similar).

- The mounting screws (and if applicable the

nuts) must be strength class 8.8 or higher.

X

The mounting screws must be tightened to the

specied torque, which depends on the strength

class (min. 8.8) of the screws/nuts used.

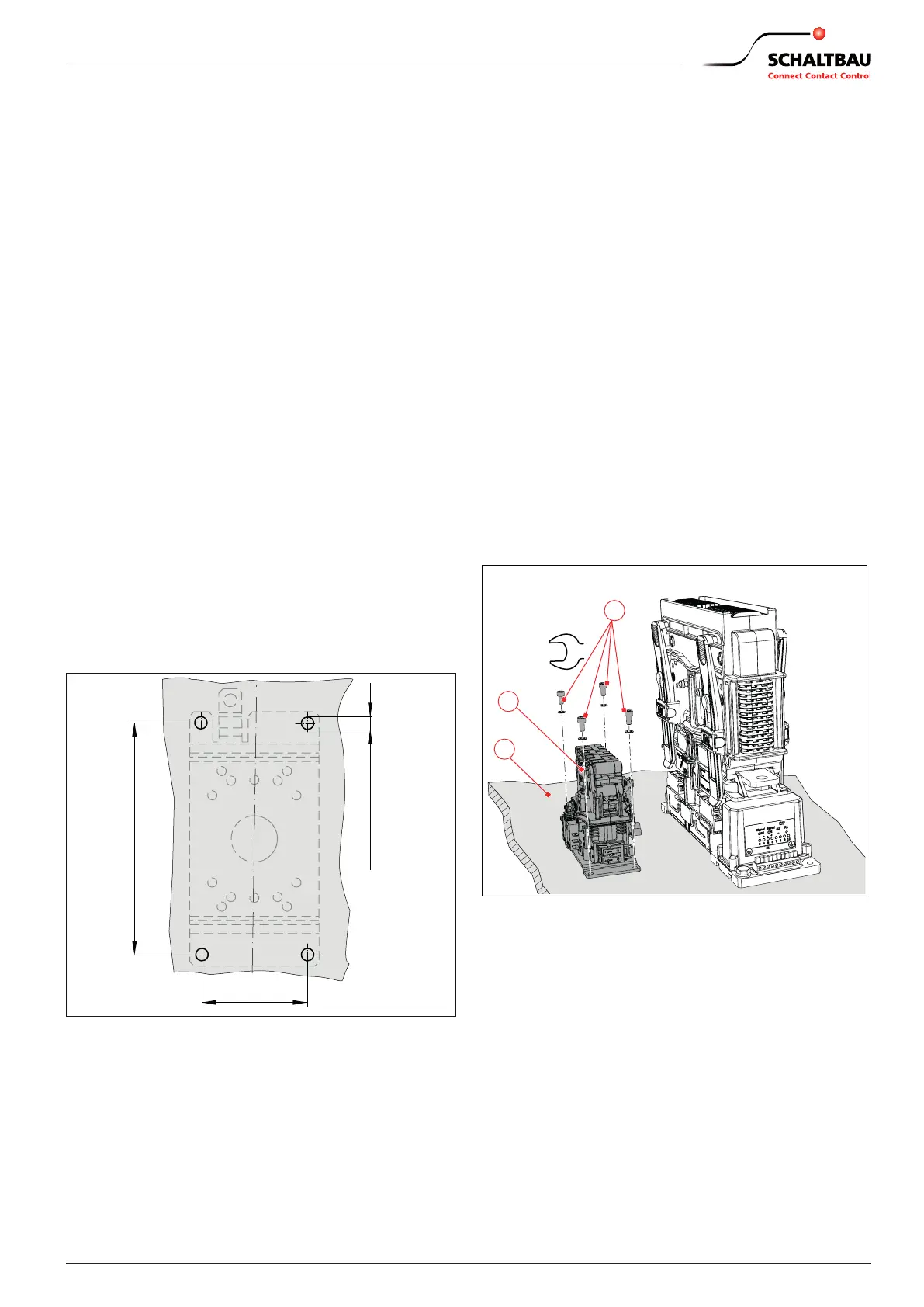

[mm]

or M5 4 x Ø 6±0.1

51±0.1

111

±0.1

Fig. 16: Dimensions and arrangement of the mounting holes

for the CPP (not to scale)

Installation procedure

X

Ensure that the contact surfaces on the mount-

ing plate (3) and the bottom of the CPP (1) are

free from dirt and other contamination (e.g. metal

chips).

X

Position the CPP (1) on the mounting plate (3)

which is provided with mounting holes.

X

Screw the CPP (1) on the mounting ange to the

mounting plate (3) using 4 mounting screws M5

including washers (2).

- In designs with the mounting holes imple-

mented as threaded holes, screw the mounting

screws into the holes directly, not forgetting the

washers.

- In designs with through holes, t the mounting

screws and washers and tighten the screws us-

ing suitable screw locking elements and nuts.

X

Tighten the mounting screws to the specied

torque, which depends on the strength class (min.

8.8) of the screws/nuts used.

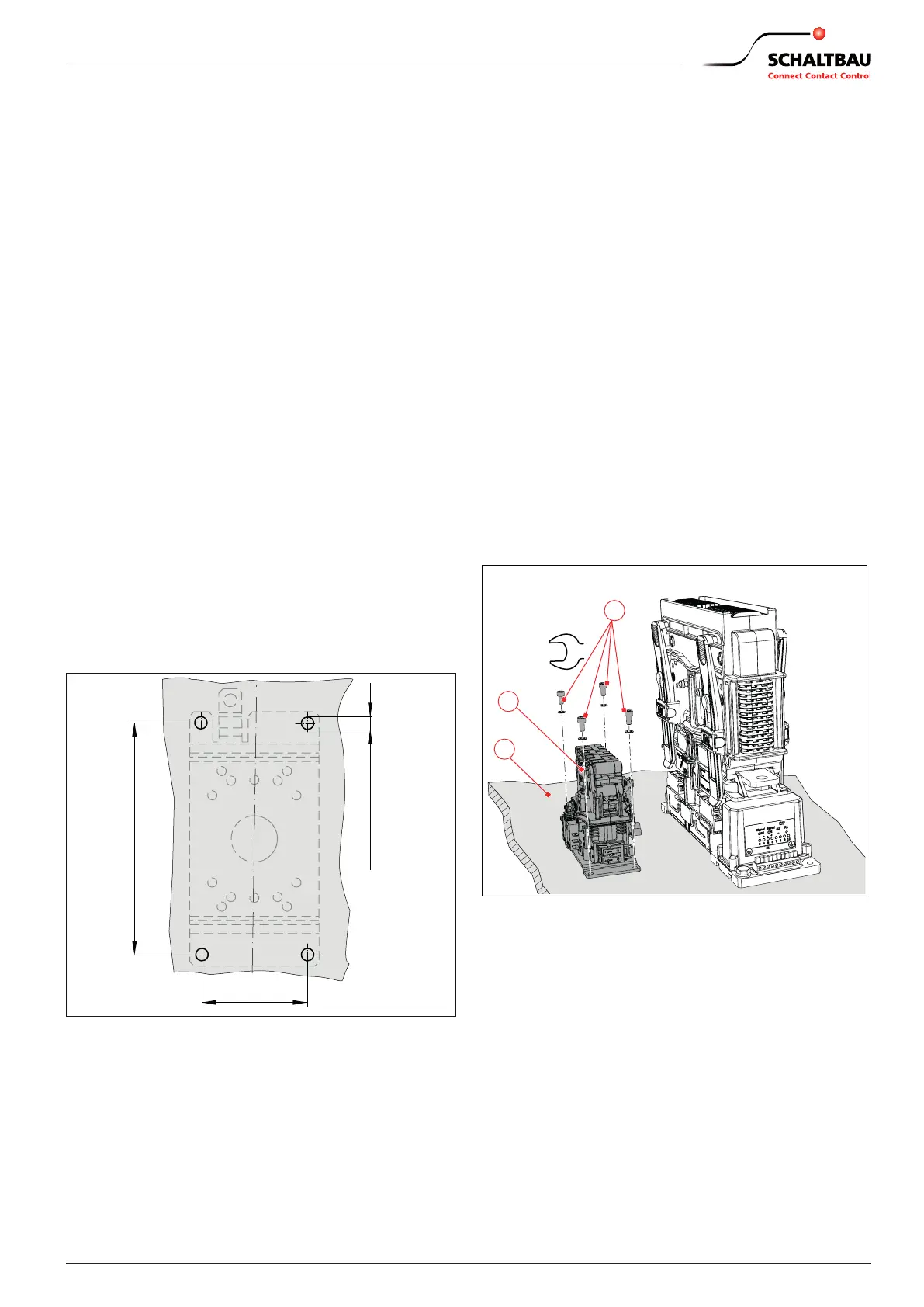

3

2

Nm

1

Fig. 17: 600 A devices: Example for the installation of the CPP

at a separate mounting position next to the main

contactor

Loading...

Loading...