17

2021-04-12 / V1.1

Contactors CP Series – Installation and Maintenance Instructions

Installation

NOTICE

When installing, ensure that no dirt can get into the

contactor as a result of surrounding building activi-

ties.

NOTICE

Detent-edged rings and detent-edged washers have

a limited life time. After screws secured with detent-

edged rings or detent-edged washers have been

undone three times, the rings or washers must be

replaced by new ones.

X

Record the frequency of undoing of the screws

in the work log.

X

Replace detent-edged rings or detent-edged

washers with new ones after the screws have

been undone three times.

8.2.6 Tools required

- Socket spanner set, hexagon nuts

- Open-ended spanner set

- Torque wrench

8.2.7 Installation procedure

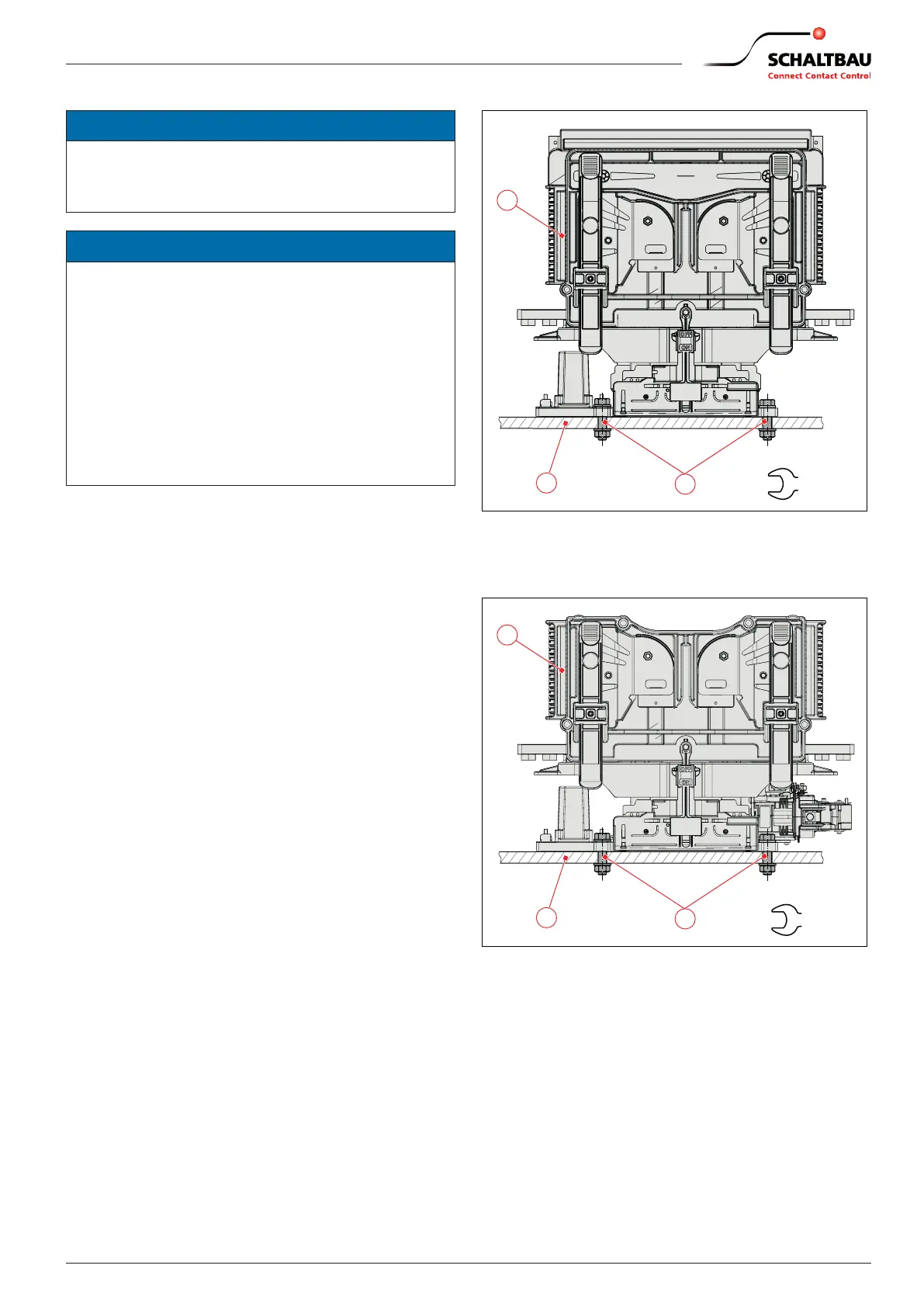

X

Make sure that the mounting surface on the

mounting plate (3) or mounting frame and the

bottom of the contactor are free from dirt and

other contaminants (e.g. metal chips).

X

Place the contactor (1) on the mounting plate (3)

or the mounting frame provided with the mount-

ing holes.

X

Screw the contactor (1) to the mounting plate (3)

or mounting frame using the 4 mounting screws

(2).

- If the mounting holes are designed as threaded

holes, screw the screws with suitable screw lock-

ing elements directly into the prepared threads.

- If the mounting holes are through holes, tighten

the screws with suitable screw locking elements

(on both sides) and nuts.

X

Tightened the mounting screws to the specied

torque, which depends on the strength class (min.

8.8) of the screws/nuts used.

3

2

1

Nm

4 x M8

Fig. 11: Example for the installation of the device on a mount-

ing plate or mounting frame (the gure shows a NO/

NC device with large arc chamber)

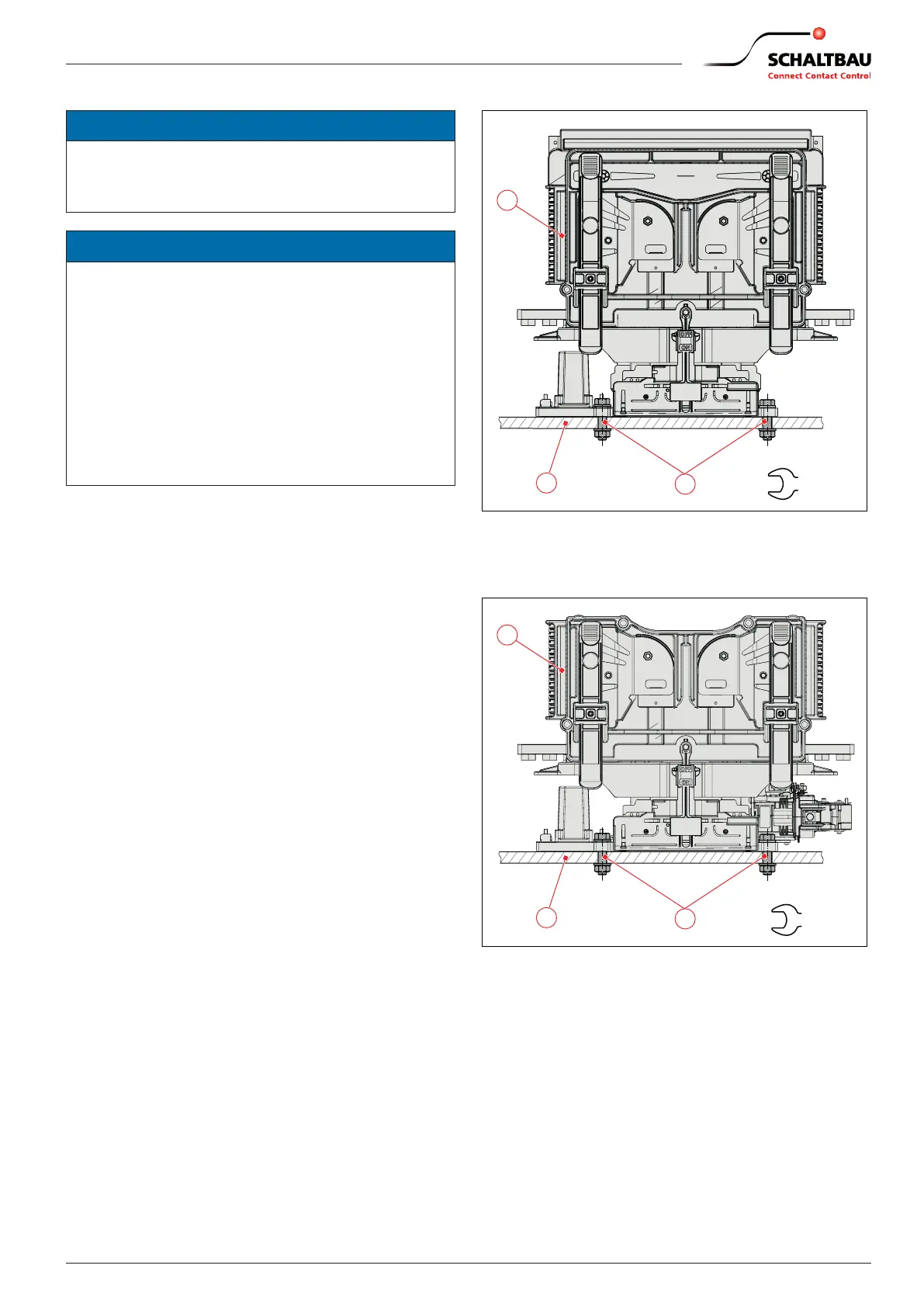

3

2

1

Nm

4 x M8

Fig. 12: Example for the installation of the device on a mount-

ing plate or mounting frame (the gure shows a NO/

NC device with medium arc chamber)

Loading...

Loading...