Schindler 3100/3300/6300 J 43402603 / 01 78/269

Copyright © 2017 INVENTIO AG

Liability Neither the manufacturer nor the installer can be held liable by the owner of the

installation for any damage which occurs as a result of using modified parts, non-original

or non matching quality spare parts or components which have not been tested by the

installer.

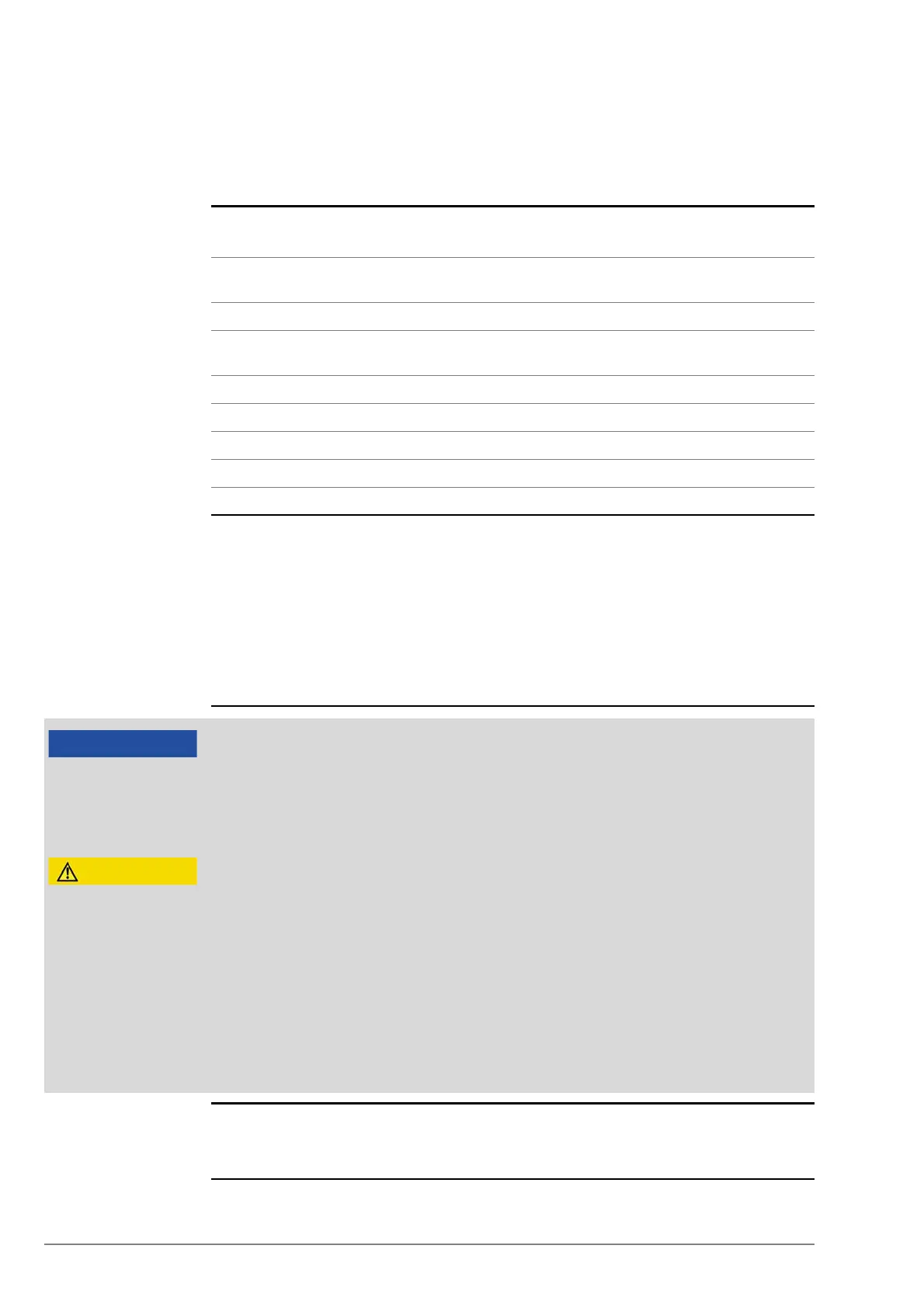

4.5.1 List of Lubricants

4.6 Periodical Examinations and Tests after Significant

Modifications and Incidents

Scope The periodical examinations and tests consist of the safety check of the installation. The

purpose of "Periodical Examinations and Tests after Significant Modifications or Critical

Incidents" is to ensure that the installation conforms to the regulations.

Registration in the

Logbook

Periodical examinations and tests after significant modifications or critical incidents must

be recorded in the logbook and a copy of the inspection report must be attached.

Component Type of

Lubricant

Comments

Gearless motor --- No lubrication needed

Car and Counterweight guide rails i) HLP68

ii) HH150

For colder countries

For warmer countries

Traction media --- Lubrication not allowed!

Speed governor rope --- Lubrication not allowed!

Door system (car and landing doors) --- No lubrication needed

Car and Counterweight diverting pulleys --- No lubrication needed

NOTICE

Responsibility

A notified body in accordance with local or national regulations could carry out any

type of inspection.

If there are no specific regulations, the owner of the installation has to mandate a

Notified Body or the maintenance company.

CAUTION

Safety Precautions

Before starting a periodic or special examination, precautions must be taken to

eliminate risks to persons or property. In particular:

– The prerequisites for maintenance according to chapter "Maintenance

Operations/Prerequisites" must be fulfilled to allow preventive maintenance

– Entrances to the hoistway (maintenance doors) and to the machine room must be

closed off for unauthorized persons

– Notices must be displayed indicating that the elevator is out of operation

– Any unsafe conditions (defective hoistway lighting, missing ladder, etc.) relevant to

carrying out preventive maintenance must be reported immediately to the owner of

installation.

Loading...

Loading...