02.00 | KSP3, KSP3-LH, KSP3-F | Assembly and Operating Manual | en |

1463318

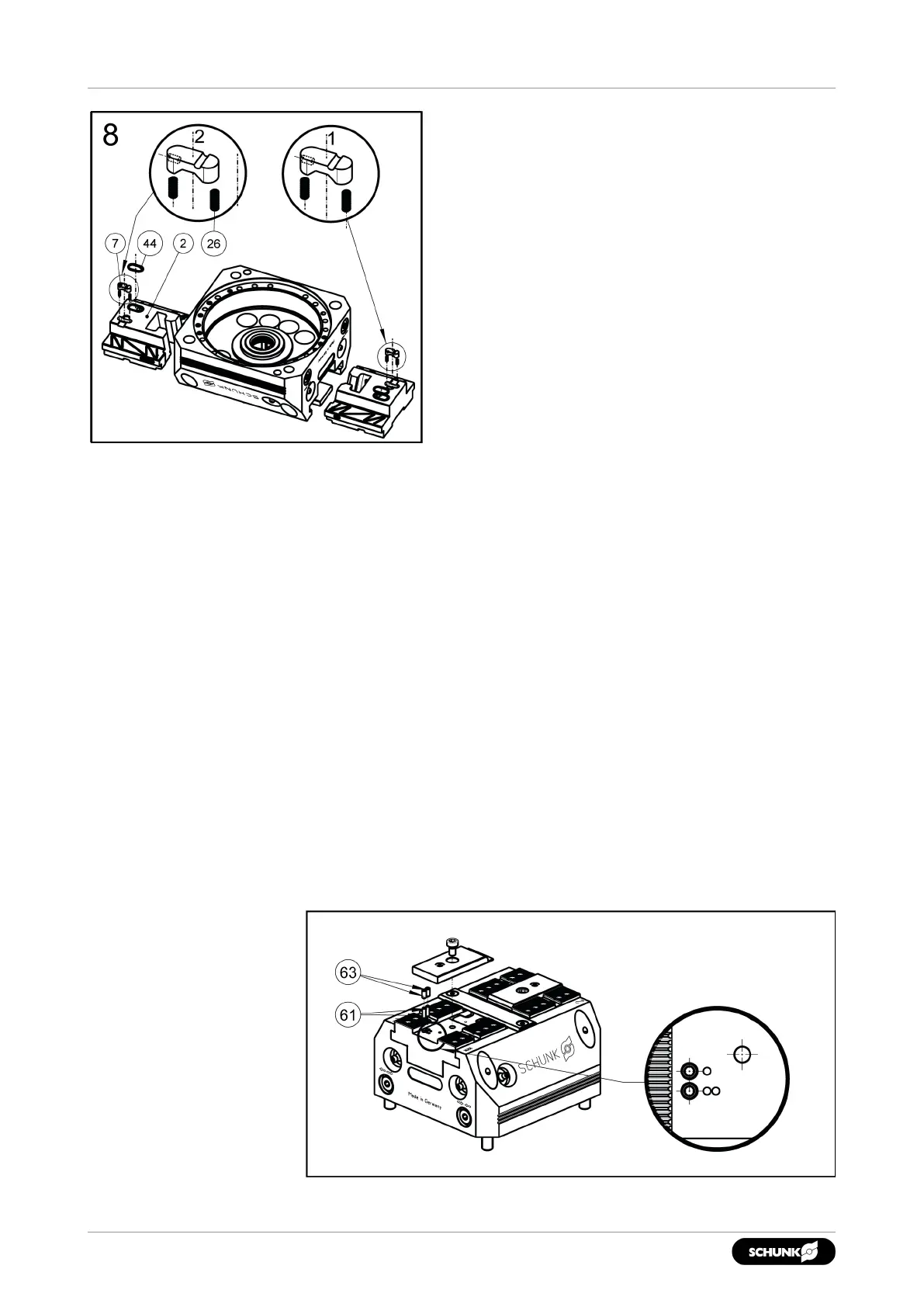

Pull the base jaws (2) out of the housing.

Variant "PM" also includes O-ring (44),

monitoring piece (7) and compression springs

(26).

Caution! The monitoring piece is under spring

pre-load and is installed directionally oriented

for each base jaw! See detail views for jaw 1

and jaw 2!

Maintenance • Clean all parts thoroughly and check for damage and wear.

• Treat all greasing areas with lubricant

}

7.3 [

/

29].

• Replace all wearing parts and seals if necessary

}

8.1 [

/

37].

Assembly Assembly is done in the reverse order of disassembly. In doing so,

observe the following.

• Ensure the mounting position of the base jaws (item 2) and the

chuck piston (item 3).

• Observe the tightening torques for the screws

}

4 [

/

17].

•

After completion of the assembly, carry out a leak test and a

function test.

}

7.4.3 [

/

36]

• For variants with clamping force maintenance (AS), mount the

cylinder piston using an assembly device Assembly

devices

}

7.4.4 [

/

000]

• Variant "PM": Pay attention to the correct alignment of the

monitoring pieces! Readjust the pneumatic jaw end position

control before mounting the guide rails (6).

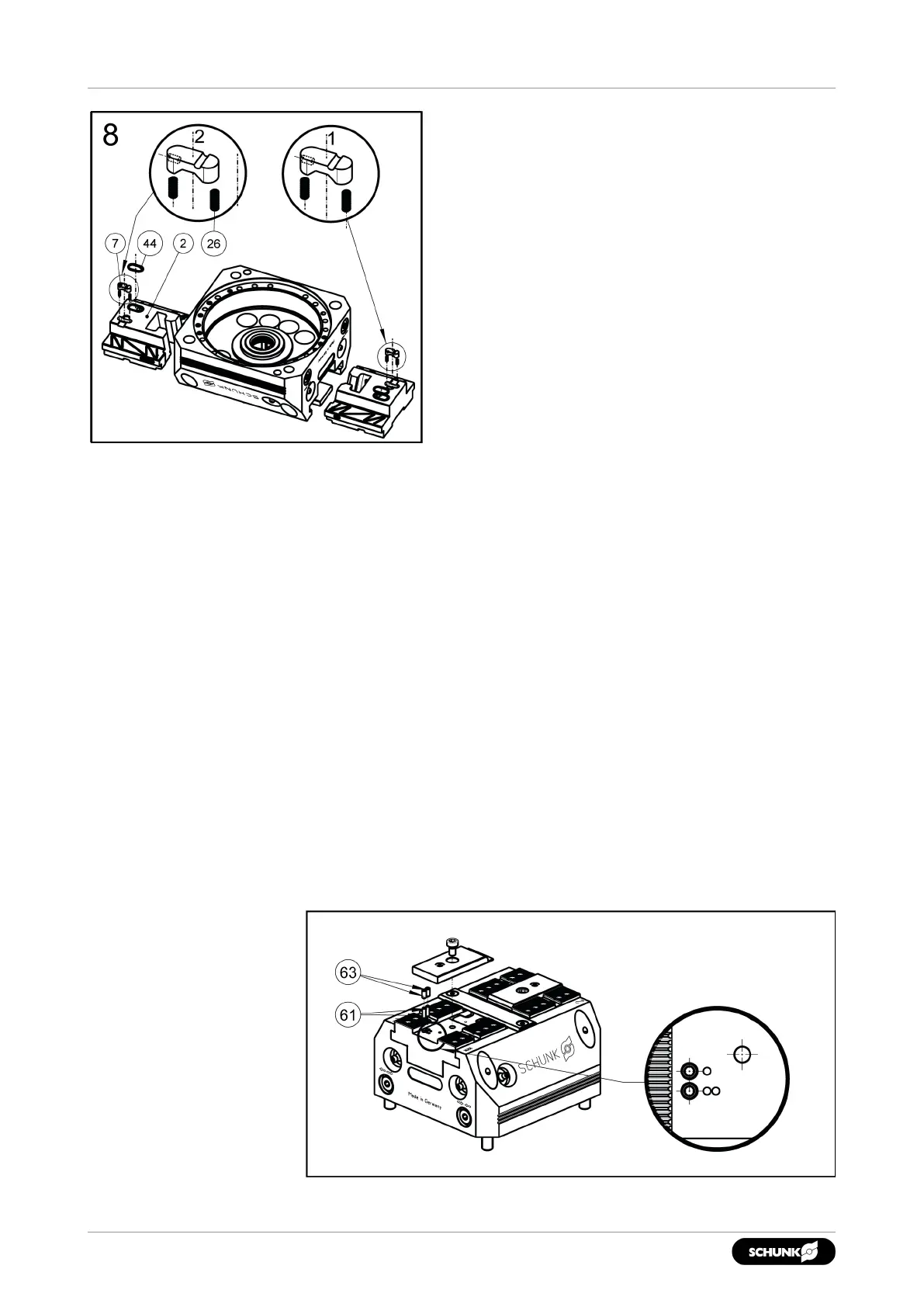

Adjustment of pneumatic jaw end position monitoring

Loading...

Loading...