Testing the Monitor 31

SCOTT SAFETY 087-0065 REV B

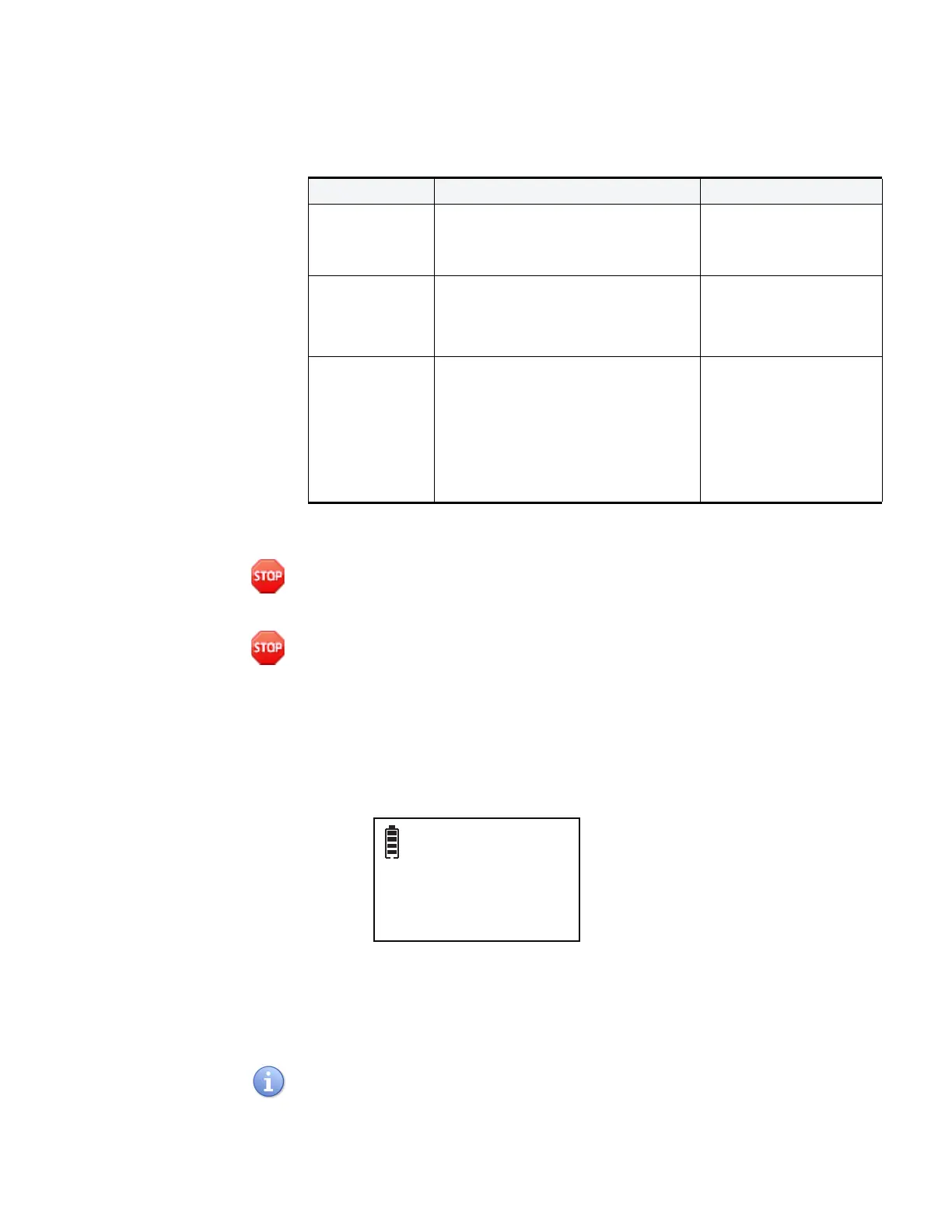

Table details the recommended calibration and test items for the device.

Zero Calibration This section describes how to perform Zero Calibration.

Warning: Only perform O

2

calibration in normal air (20.9% Oxygen) that is free of

hazardous gases. During the Zero Calibration, any installed oxygen sensor will be

spanned to 20.9% O

2

.

Warning: Do not perform a zero calibration anywhere from 5 minutes to

1

/

2

hour after

the start up to ensure accuracy. Failure to follow these instructions may also result in

serious injury or death.

1 Verify ambient air is free of toxic or combustible gases. If air is not free or cannot

be verified free, obtain a Zero Air gas cylinder.

2 Press and hold the right button, a screen appears stating Zero Calibration.

Figure 13 Zero Calibration Screens

3 Press the left button, the device displays AIR CLN (Is air clean?). If yes, press the

left button to acknowledge the zero calibration and it will countdown.

4 If the air is not clean, press the right button to cancel the zero calibration.

The user has 60 seconds to acknowledge the alert, if the alert is not acknowledged

within 60 seconds, the device goes to the span calibration.

Table 15 Recommended Calibration and Test Matrix

ITEM FREQUENCY DETAILS

Zero Calibration • When baseline readings are incorrect

or suspect

• Prior to a Span Calibration

See “Zero Calibration”

on page 31

Span Calibration • CAL EXPIRED is displayed

• After installing new sensors

• When a Bump Test fails

See “Span Calibration”

on page 33

Bump Test • Daily

• When a sensor is exposed to a high

concentration of gas

• When submerged in water

• When exposed to mechanical shock,

such as being dropped

See “Bump Test” on

page 35

Loading...

Loading...