2.21

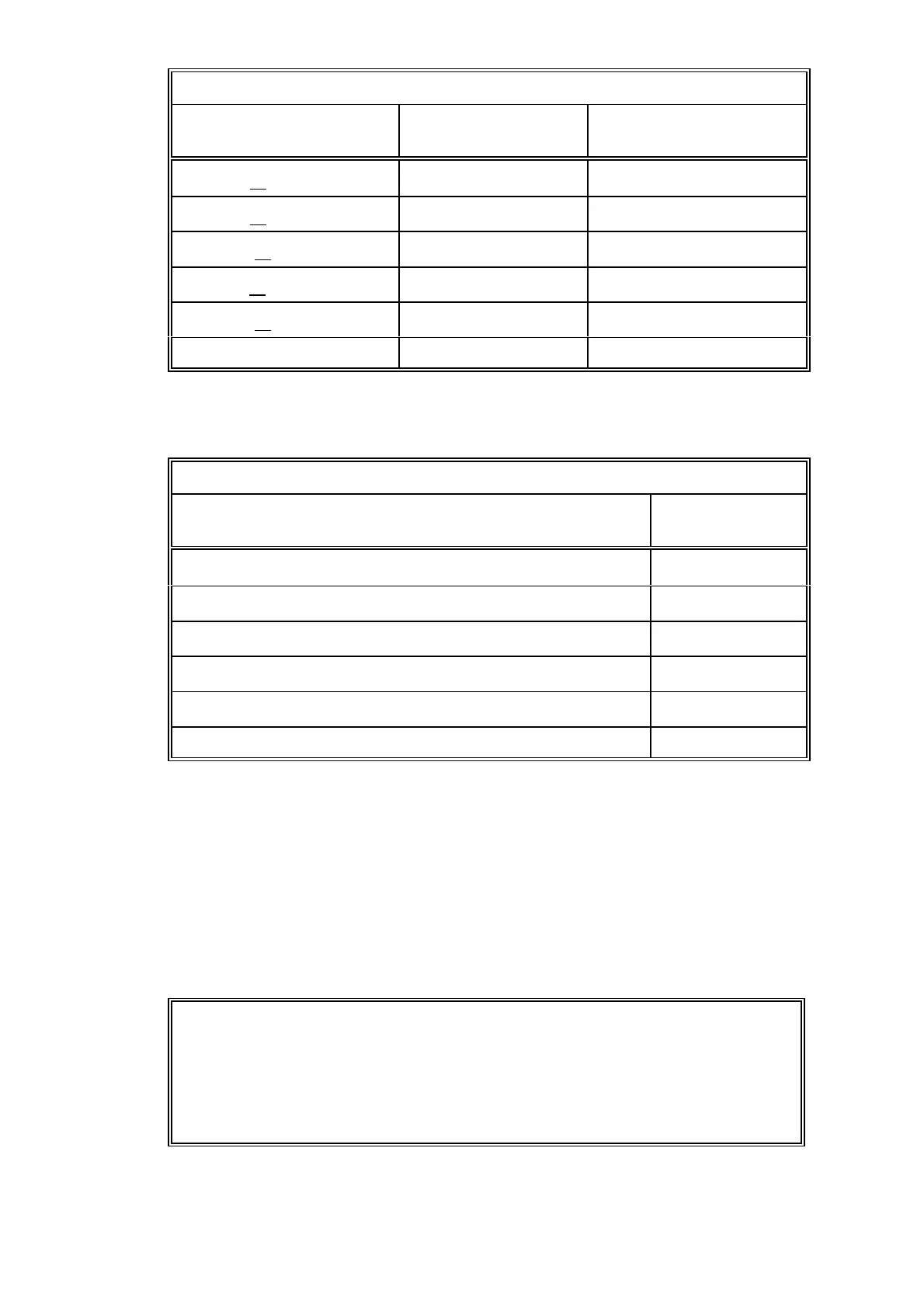

Table 2.10 Recommended calibration gases

Gas Components

Measured

Calibration gas 1 Calibration gas 2

CO only or CO+O

2

“zero grade” N

2

*

CO in air gas mix

NO only or NO+O

2

NO in N

2

gas mix Air

SO

2

only or SO

2

+O

2

“zero grade” N

2

*

SO

2

in air gas mix

CO+NO or

CO+NO+O

2

NO in N

2

gas mix CO in air gas mix

CO+SO

2

or CO+SO

2

+O

2

“zero grade” N

2

*

CO, SO

2

in air gas mix

NO+SO

2

or NO+SO

2

+O

2

NO in N

2

gas mix SO

2

in air gas mix

* Zero grade nitrogen is 99.998% purity with total impurities not exceeding 20

vpm.

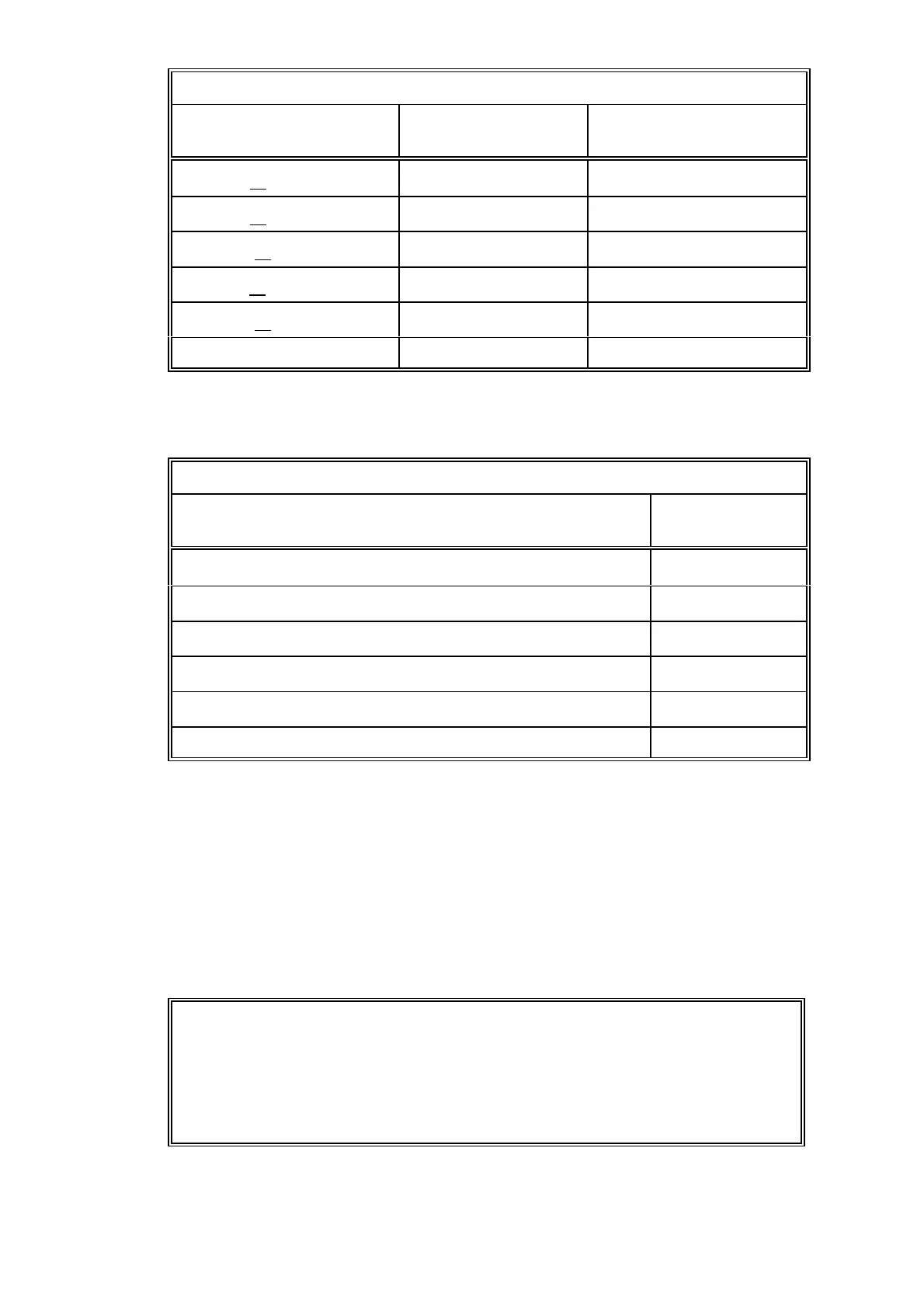

Table 2.11 Recommended component concentrations

Gas Measured Recommended

calibration level

Paramagnetic O

2

21%

Gfx High sensitivity CO (0-50 to 0-500 vpm) 50 vpm

Gfx Standard sensitivity CO (0-200 to 0-3000 vpm) 200 vpm

Gfx NO (0-100 to 0-500 vpm) 100 vpm

Gfx High sensitivity SO

2

(0-100 to 0-500 vpm) 100 vpm

Gfx Standard sensitivity SO

2

500 vpm

The accuracy of the calibration materials used with the analyser is an important

contribution to the quality of the data measured. Servomex recommend that the

xentra 4900 Continuous Emissions Analyser be calibrated using certified gravimetric

gas mixtures from a reputable supplier. These should be accompanied by a

compositional analysis certificate of certified accuracy . Pressure regulators used

with the calibration gas mixtures should be good quality two stage regulators

compatible with the gas composition. The calibration gas supply pressure will be in

the range 1-5 psig. The pressure regulators should provide a stable delivery

pressure of 0-10 psig ( 0-1 bar ) at a standard flow rate of up to 2l/minute.

WARNING

The sample and calibration gases supplied to the instrument may be

toxic. Verify that connections are leak free at full operating pressure

before proceeding to admit toxic gases.

Loading...

Loading...