656 229 2010-11-22| Sicam snc società unipersonale

32 | SBM 855 | Fitting and removing the fl angeen

5. Fitting and removing the

flange

Fitting of the flange is necessary in the following

situations:

Commissioning

When changing the type of flange

(centering flange, universal flange, special flange)

When changing the type of wheel

(passenger car - truck)

! Balancing accuracy will be impaired if the flange has

not been properly fitted to the shaft.Before fitting the

flange, clean and degrease (remove corrosion protec-

tion) the cone of the shaft and the flange opening.

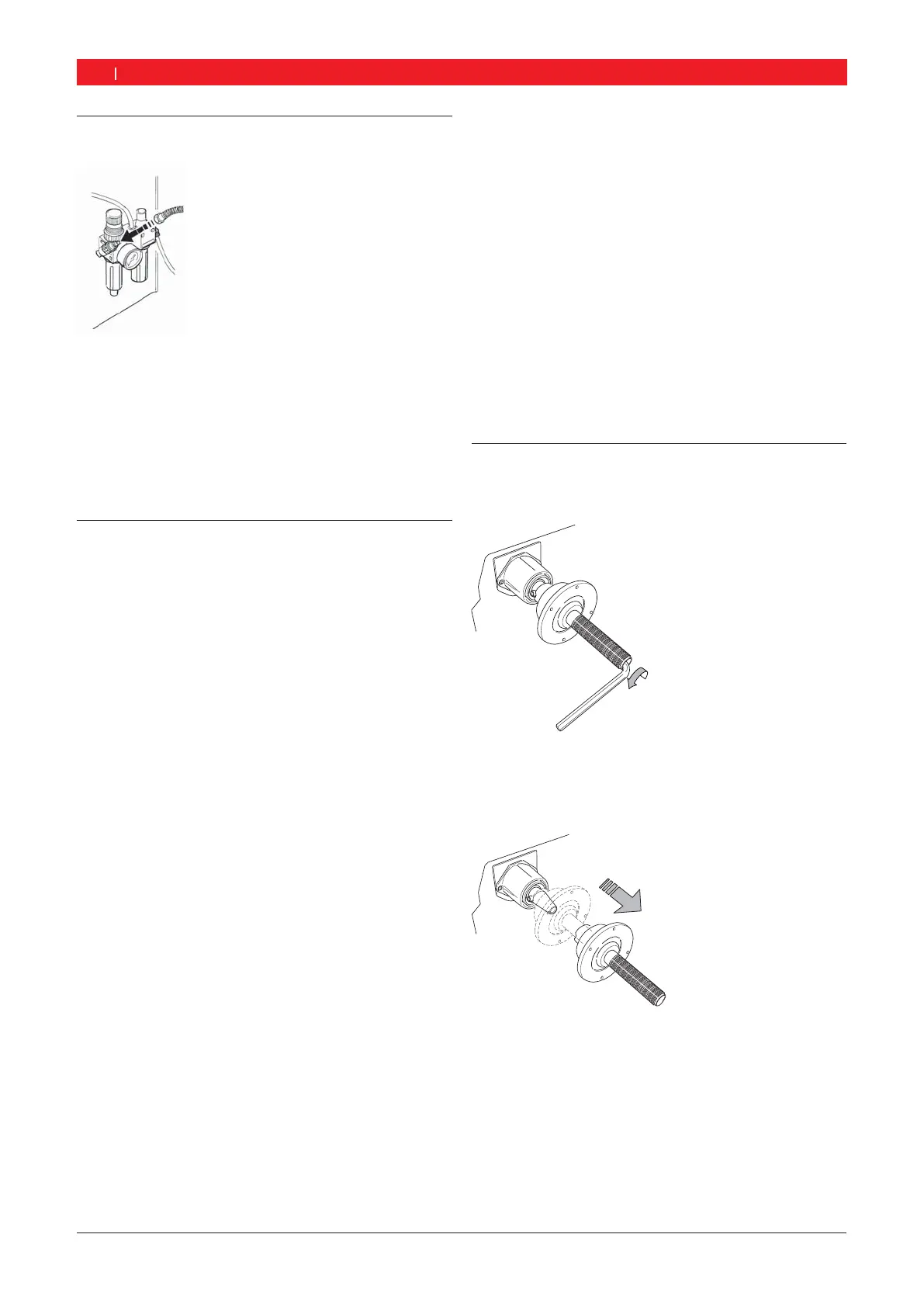

5.1 Removing the flange

1. Slacken off the hexagon socket head bolt.

651002-04 _Rf

2. Unfasten the flange by tapping with a rubber-headed

hammer on the cone end.

3. Pull the flange off the cone.

651002-06 _Rf

"Flange detached.

6.5 Compressed air connection

1. Connect the SBM 855 to the compressed air supply.

651003-05 _Rf

2. Set a pressure of between 8 bar and 12 bar.

First pull the pressure reducer (red knurled

screw) upwards and then turn to set the pressure

to between 8 and 12 bar.

Check the pressure on the pressure gauge.

! The pressure must never exceed 12 bar!

6.6 Calibration of SBM 855

!

Calibration must be performed after initial commis-

sioning.

1. Flange calibration.

2. SBM 855 calibration.

3. Perform reference measurement.

i Calibration is described in Section 12.4

Loading...

Loading...