656 229 2010-11-22| Sicam snc società unipersonale

42 | SBM 855 | Faultsen

11. Faults

i Other possible malfunctions are primarily of a technical nature and are to be checked and if necessary rectified

by a qualified engineer. Always contact the customer service of your authorized Sicam equipment dealer.

i To enable action to be taken quickly, it is important to inform customer service of the specifications on the rat-

ing plate (label on the flange end of the SBM 855) and the nature of the problem.

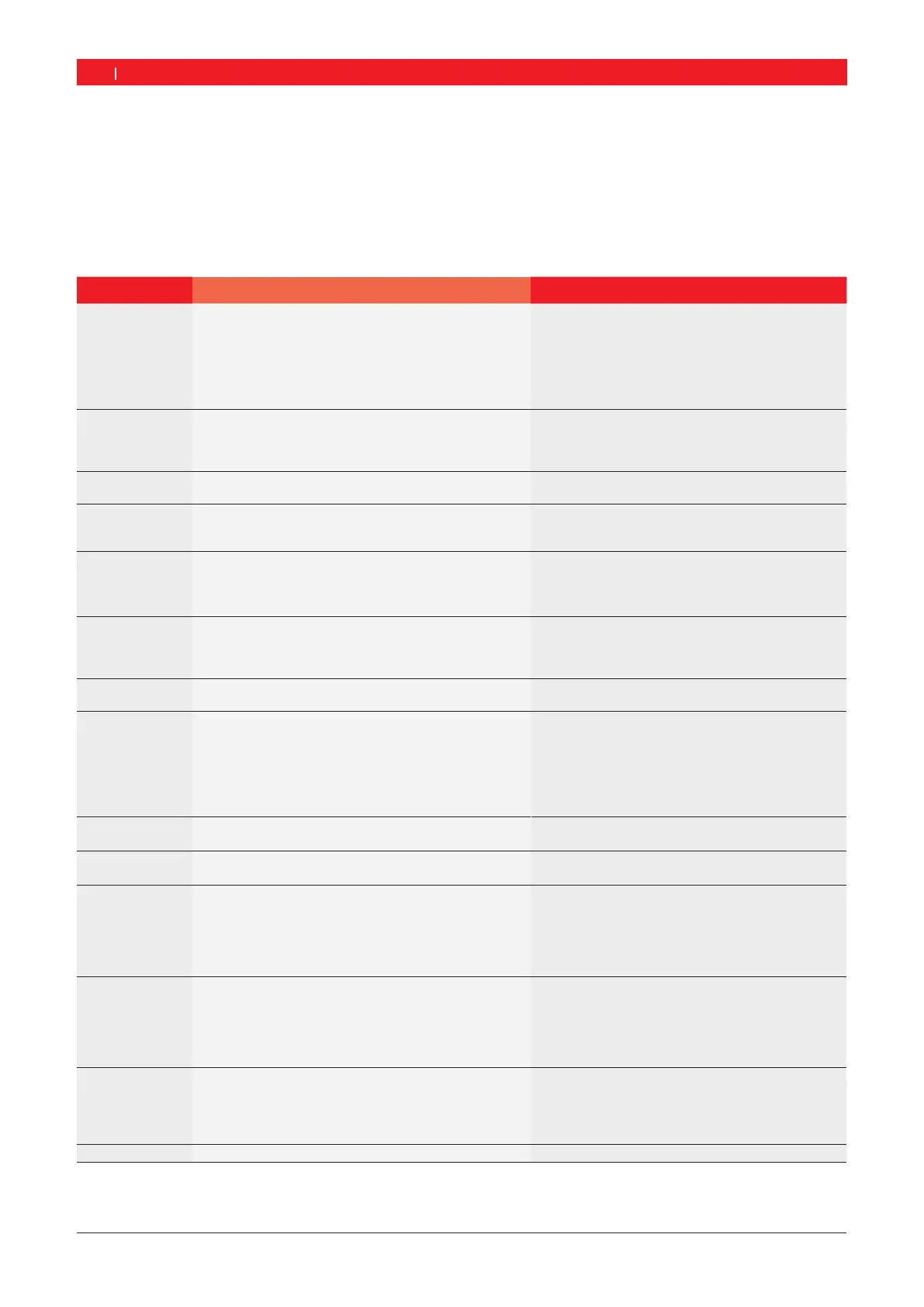

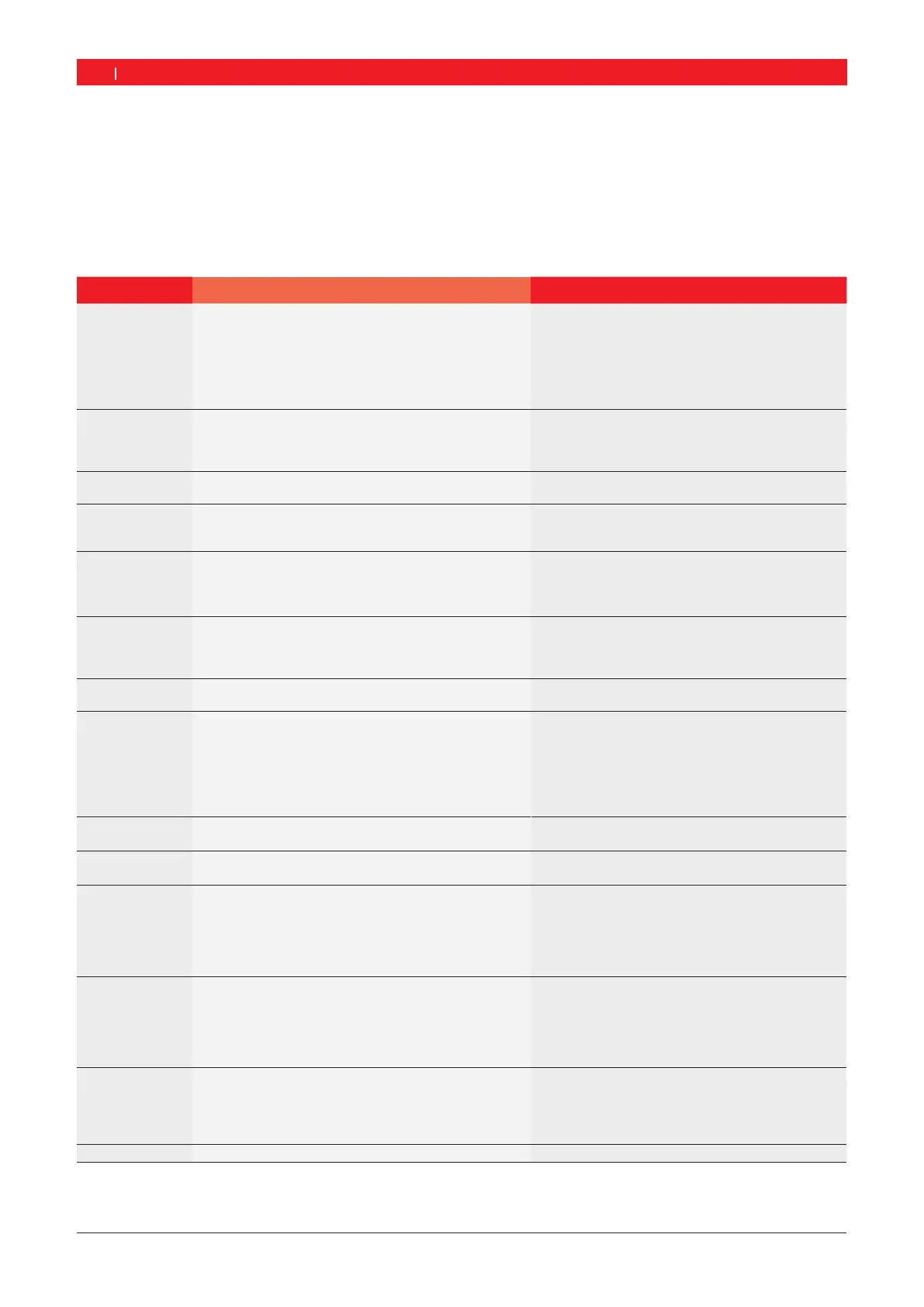

Faults Causes Remedy

The displays

do not light on

switch-on

1. Defective fuse or missing phase

2. Damaged fuse in electrical connection

3. Damaged fuse in control/display panel

1. Check the mains connection.

2. Replace the fuse in the electrical connection.

3. Replace the fuse in the control/display panel. In-

form customer service.

Caution: Repeated fuse damage is an indication of a

malfunction.

1 1. Setting and calibration data lost from PCB memory

2. One or more calibration operations (setting, calibrati-

on of electronic vernier caliper/gauge arm) not perfor-

med

Check and correct calibration and settings.

2 Wheel guard raised prior to completion of measurement Wait for end of measurement before raising wheel

guard.

3 1. Backward rotation of wheel on start of measurement

2. Incorrect connection of motor

1. Check that wheel is stationary on starting and stop

it turning backwards on starting.

2. Check proper connection of motor.

4 1. No motor operation, motor does not attain the neces-

sary speed

2. Fault in electrical connection

3. Fault in PCB

1. Check mains voltage (probably too low).

2. Check electrical connection or power cord.

3. Replace the PCB.

5 1. Balance weight not attached to wheel

2. Measurement sensors not correctly connected

1. Repeat calibration from the start and attach balan-

ce weight as specified by the process.

(refer to 12.4 ).

2. Check the connection of the measurement sensors.

6 1. Wheel guard not lowered

2. Damage to wheel guard safety switch

1. Lower wheel guard with wheel attached.

2. Replace wheel guard switch.

7 Excessive phase difference between the 2 measurement

sensors

1. Check for correct attachment of

calibration weight.

2. Check machine connection; SBM 855 probably not

stable and vibrating excessively.

3. Check contact between measurement sensor and

PCB.

4. Replace measurement sensor.

5. Replace PCB.

8 Inner measurement sensor not correctly connected, de-

fective or open circuit in wire

1. Check connection of left measurement sensor.

2. Replace measurement sensor.

9 Outer measurement sensor not correctly connected, de-

fective or open circuit in wire

1. Check connection of right measurement sensor.

2. Replace measurement sensor.

10 1. Measurement sensor for position recognition defective

2. No motor operation

1. Check connection of light barrier PCB.

2. Check that the light barrier PCB is protected

against light and provide a cover if necessary.

3. If the fault persists, check and if necessary replace

the light barrier PCB.

4. Check the mains connection.

11 1. Measurement sensor for phase recognition defective

2. No motor operation

1. Check connection of light barrier PCB.

2. Make sure the light barrier PCB is protected

against light and provide a cover if necessary.

3. Check and if necessary replace the light barrier

PCB.

4. Check the mains connection.

17 Weight outside setting range (weight required for balan-

cing is more than 250 g)

1. Check whether the wheel is correctly attached to

the flange.

2. Determine the outer weight position (neverthe-

less), attach a 100 g weight and start a different

measurement.

18 Wheel data not entered Enter wheel data before performing measurement.

Loading...

Loading...