Page EN-8 XPS/XCT Series Transducers – OPERATION MANUAL 7ML19985QM82

English

Mounting – Liquid Applications (cont’d)

Installation

• Do not route cable openly. For optimum isolation against electrical noise, run cable

separately in a grounded metal conduit. Seal all thread connections to prevent ingress of

moisture.

• Do not run cable near high voltage or current runs, contactors, and SCR control drives.

For pressure tight applications, install transducers hand tight plus ½ to 1½ turns.

• PTFE tape or other appropriate sealant may be used to aid in sealing the threads for use

in pressure applications.

Note: Installation shall only be performed by qualified personnel and in accordance with

local governing regulations.

WARNING: Never attempt to loosen, remove, or disassemble process connection

while vessel contents are under pressure.

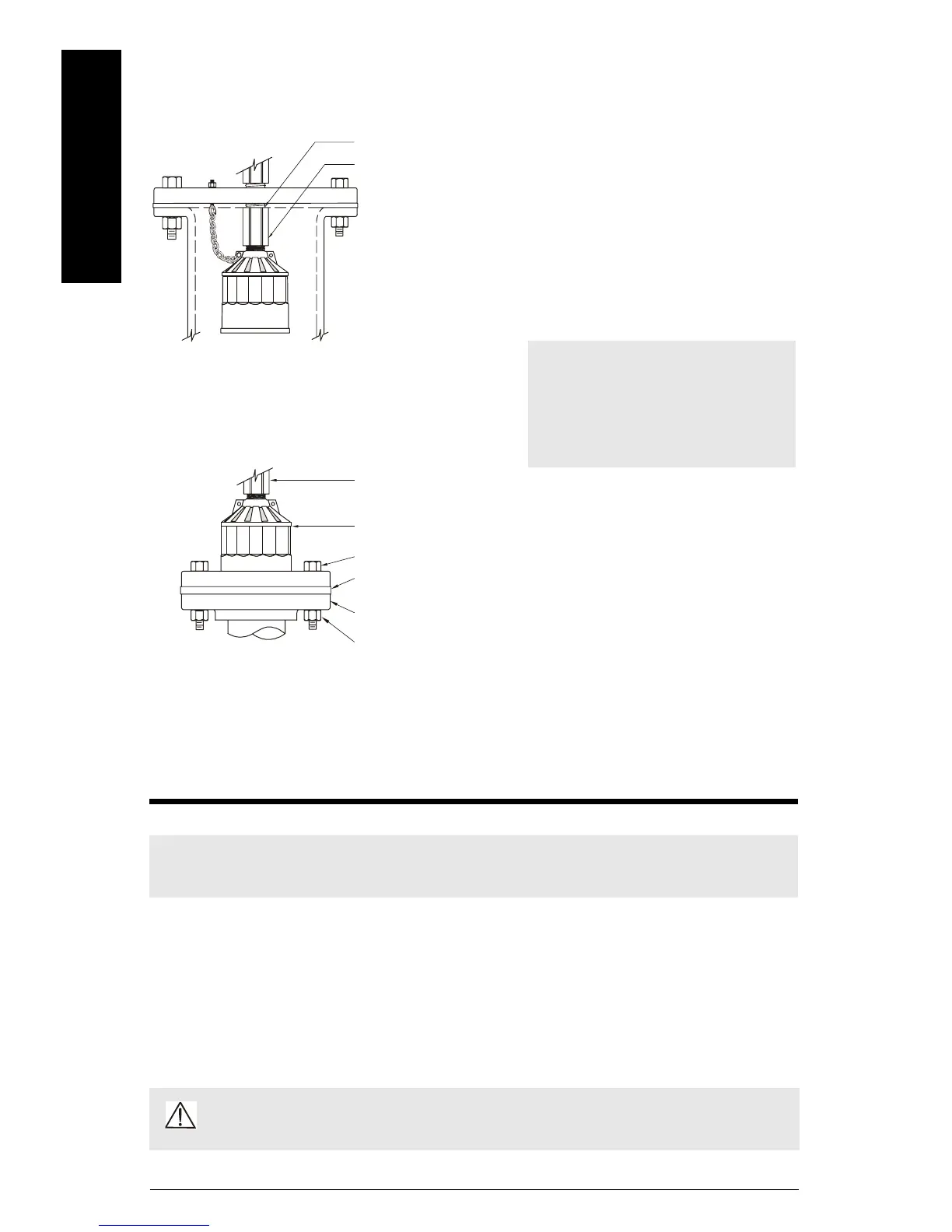

Flanged

coupling

bolt

gasket

customer flange, flat face only

Customer flanged standpipe. If a metal flange must be welded to pipe, refer

to Liquid Applications - Standpipes in the

Transducer Applications Manual

.

factory flanged transducer

nut

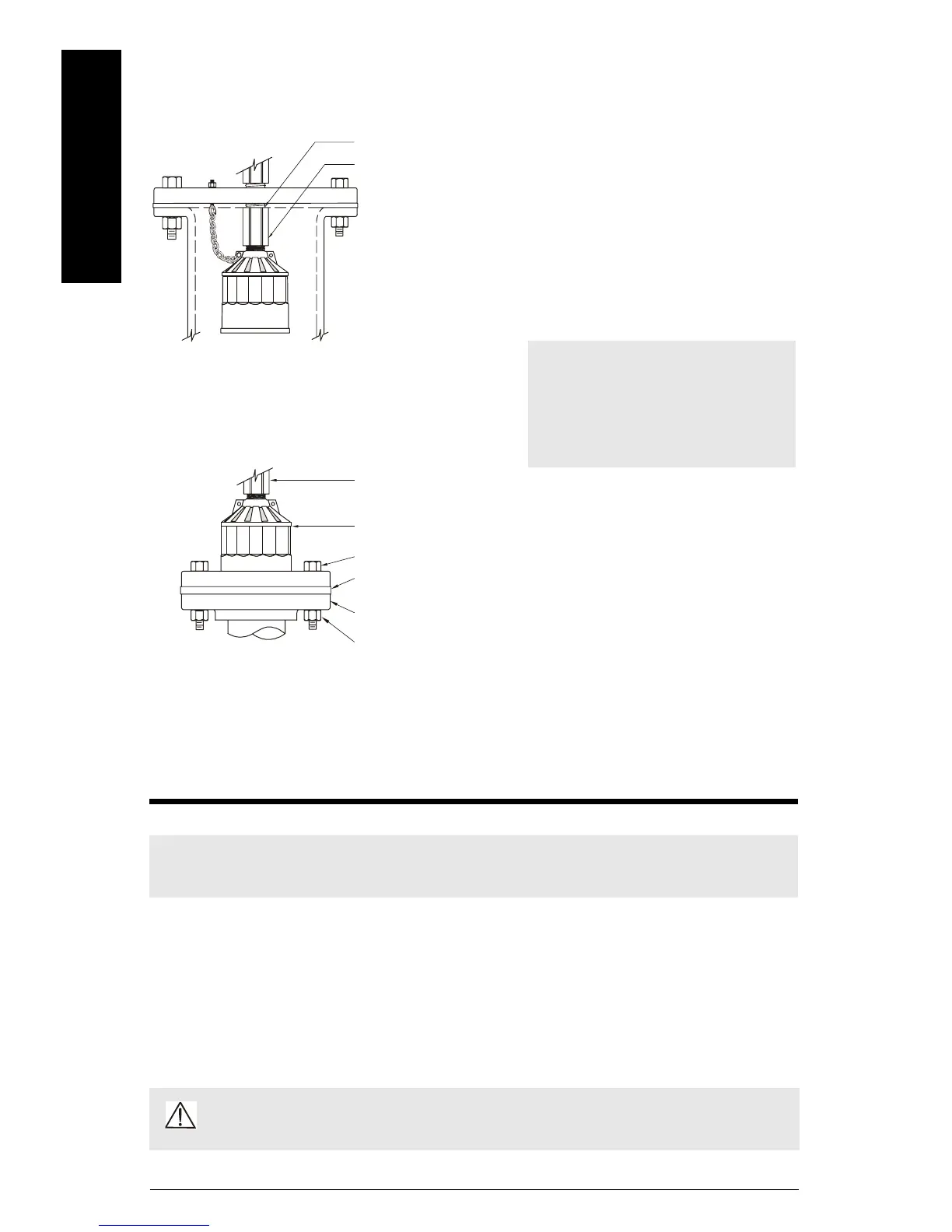

Blind Flange

nipple welded to blind flange

coupling

flange, gasket, and hardware

supplied by customer.

Note: Tighten the flange bolts

evenly in order to ensure a good

seal between the mating flanges.

Caution: Overtightening can

cause performance degradation.

Loading...

Loading...