Page EN-6 XPS/XCT Series Transducers – OPERATION MANUAL 7ML19985QM82

English

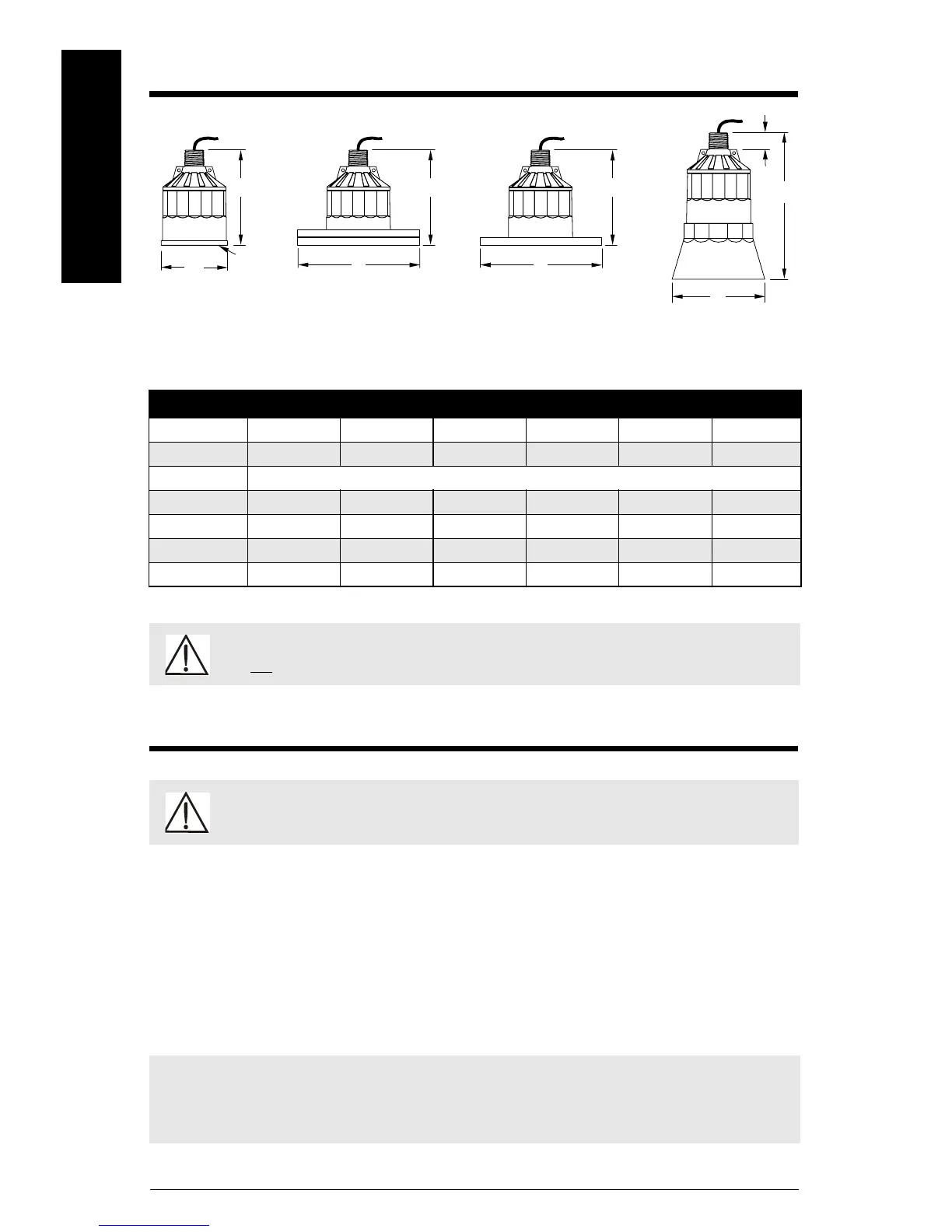

Outline and Dimensions

Mounting

• Mount the transducer so that it is above the maximum material level by at least the

blanking value. Refer to the associated controller manual.

• On liquid applications, mount the transducer face parallel to the liquid surface. On solids

applications, use a Siemens Milltronics Easy Aimer to help aim the transducer.

• Do not overtighten. Most applications require only hand tightening of the mounting

hardware. Connect a safety chain from the transducer to a structural member to secure

installation. Consider using the optional temperature sensor when a flanged transducer

is used, when a fast temperature response is required, or in high temperature vessels.

Dimension XPS-10 XPS-15 XPS-30 XPS-40 XCT-8 XCT-12

A 88 mm (3.4") 121 mm (4.8") 175 mm (6.9") 206 mm (8.1") 88 mm (3.4") 121 mm (4.8")

B 122 mm (4.8") 132 mm (5.2") 198 mm (7.8") 229 mm (9.0") 122 mm (4.8") 132 mm (5.2")

C to suit ANSI, DIN and JIS standards

D* 128 mm (5.0") 138 mm (5.4") 204 mm (8.0") 235 mm (9.2") 128 mm (5.0") 138 mm (5.4")

E 124 mm (4.9") 158 mm (6.2") n / a n / a n / a n / a

F 152 mm (6.0") 198 mm (7.8") n / a n / a n / a n / a

G 28 mm (1.1") 28 mm (1.1") 28 mm (1.1") 28 mm (1.1") 28 mm (1.1") 28 mm (1.1")

* nominal

WARNING: Optional Split Flange, Bonded Flange, and Easy Aimer configurations

are not suitable for pressure applications.

WARNING: Special handling precautions must be taken to protect the

face of the transducer from any damage.

Note: For pressure tight applications, install transducers hand tight plus ½ turn to 1½

turns. PTFE tape or other appropriate sealant may be used to aid in sealing the threads for

use in pressure applications.

B

A

C

B

F

E

C

D

G

standard

radiating

face

optional bonded flange

refer to associated instructions

optional split flange

refer to associated instructions

optional

submergence shield

refer to associated

instructions

Loading...

Loading...