More user manuals on ManualsBase.com

09.95 12 Functional Descriptions

12.30.4 Activating/deactivating the master/slave torque compensation control

For the master, function generator operation is also permitted in the SERVO and in the

SIMODRIVE 611D (start-up functions). Measurement of the position control loop (SERVO) is

made with the speed and torque coupling active. With measurement functions in the

SIMODRIVE 611D (speed and current control loop), however, only the torque compensation

controller is active. Its output must therefore be connected to the slave (bit 5 of MD

1812*/523* = 1), if measurement is performed with offset > 0.

As an alternative to the start-up functions, it is possible to deactivate the slave operation as

well and configure a GI actual-value coupling instead. The function generator operation is also

permitted for GI leading axes.

12.30.5 Response in the event of an error

In error states (alarms with request for "correction") in the master and/or slave, both drives

must be deactivated together otherwise one of them might attempt to output all the required

torque by itself. In this case, distortion or torsion in the workpiece would be avoidable. The

drives are shut down via SERVO-internal communication in the IPO cycle.

The way in which deactivation is performed can be determined by the user using the familiar

delay times:

If torqueless operation is to be activated immediately, the "OFF delay for servo enable"

(MD 156) and "Delay servo enable" (MD 1224*) must be set to 0. The global MD 156 only

applies if the axial MD 1224* is 0 and must therefore be set to 0. In this case, the servo

enables of the drive are cancelled immediately. To prevent the drive performing regenerative

braking, the drive machine data 1404 must be set to 0. The axis then coasts to rest.

If active braking is only to begin after a certain delay (with the torque of the still intact slaves or

of the master), this time must be parameterized to be the same for all slaves and for the

master in MD 1224*. It is up to the user to do this.

On spindles there is an option of braking the speed setpoint via a ramp and then disabling the

controller. Here too, the user must parameterize identically for all spindles of a master/slave

grouping.

Note:

"Extended stopping and retracting" (ESR), if programmed, cannot be taken into account for

the reason described above as soon as one axis of a master/slave grouping fails. The following

table shows an overview of the alarm responses:

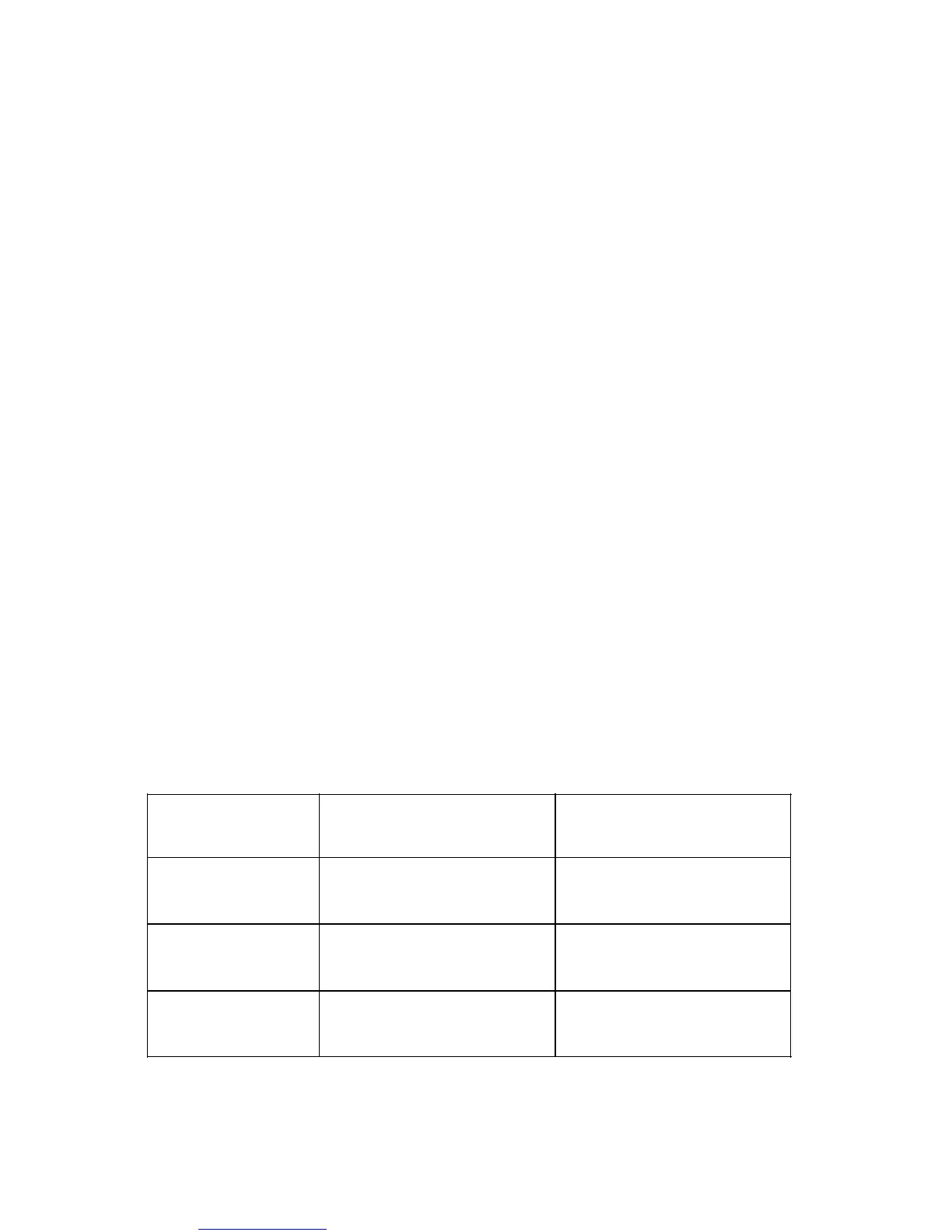

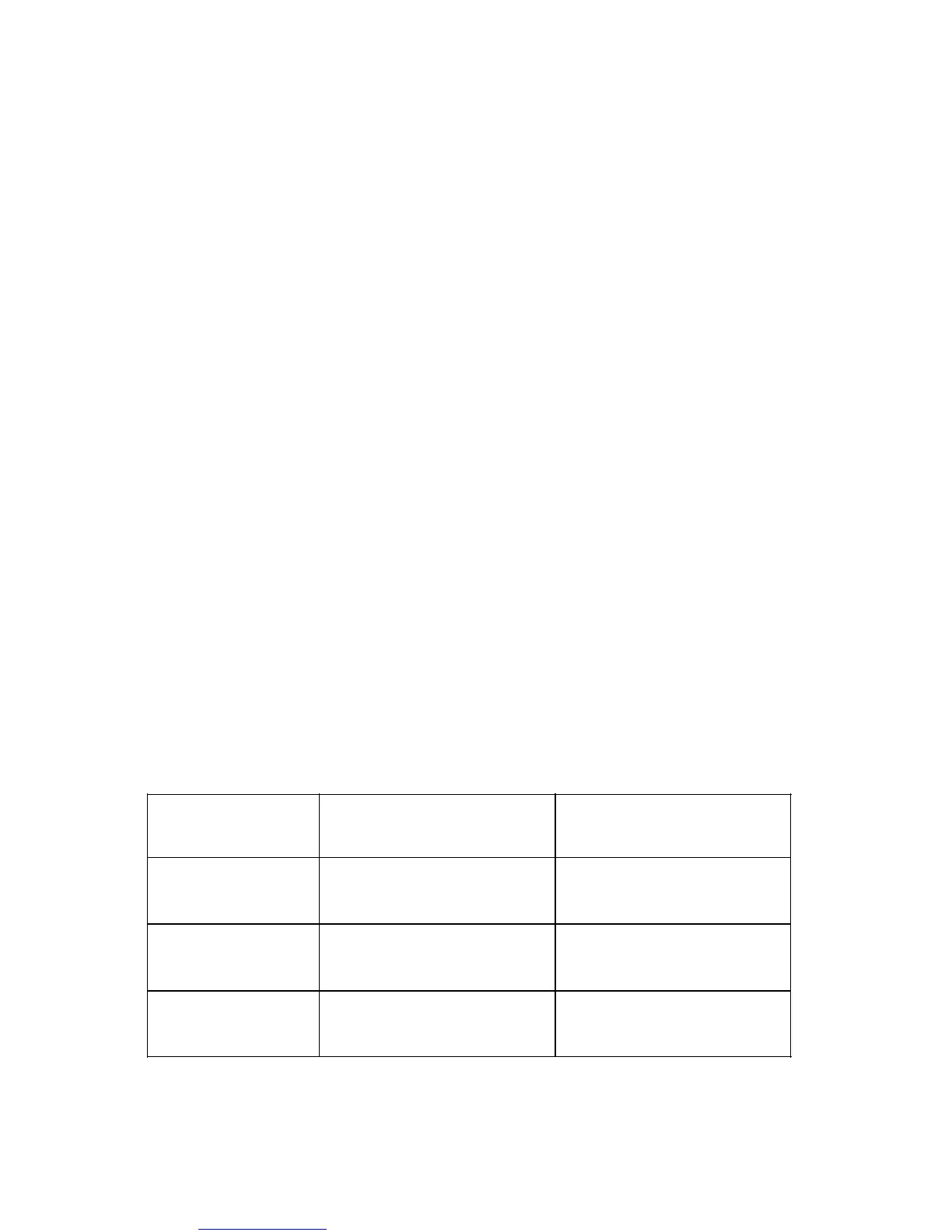

Error occurs:

1.) Normal functionality without

ESR

2.) ESR active for master and

slave

Master: Immediate initiation of follow-up

control with the parameterized

stopping times

Immediate initiation of follow-up

control with the parameterized

stopping times

Slave: Immediate initiation of follow-up

control with the parameterized

stopping times

Immediate initiation of follow-up

control with the parameterized

stopping times

Other axis in the mode

group:

Immediate initiation of follow-up

control with the parameterized

stopping times

Master + slave: configured

ESR, master/slave is retained.

© Siemens AG 1992 All Rights Reserved 6FC5197- AA50

12–309

SINUMERIK 840C (IA)

Loading...

Loading...