Mechanical mounting

6.3 Installing/removing the rotor

SIMOTICS M-1FE2 built-in motors

112 Hardware Installation Manual, 04/2020, A5E50074509B AA

Procedure for removal using the oil pressing procedure

Environmental harm due to leaking oil

The forcing of oil can cause oil to escape and result in environmental damage.

• Catch any escaping oil.

• Bind the escaping oil with a suitable oil binding agent.

• Dispose of the oil and oil binding agent in accordance with the legal regulations.

Note

Different shape

The spindle shaft is supplied by the spindle manufacturer. The shape of the spindle shaft

may differ from the illustration

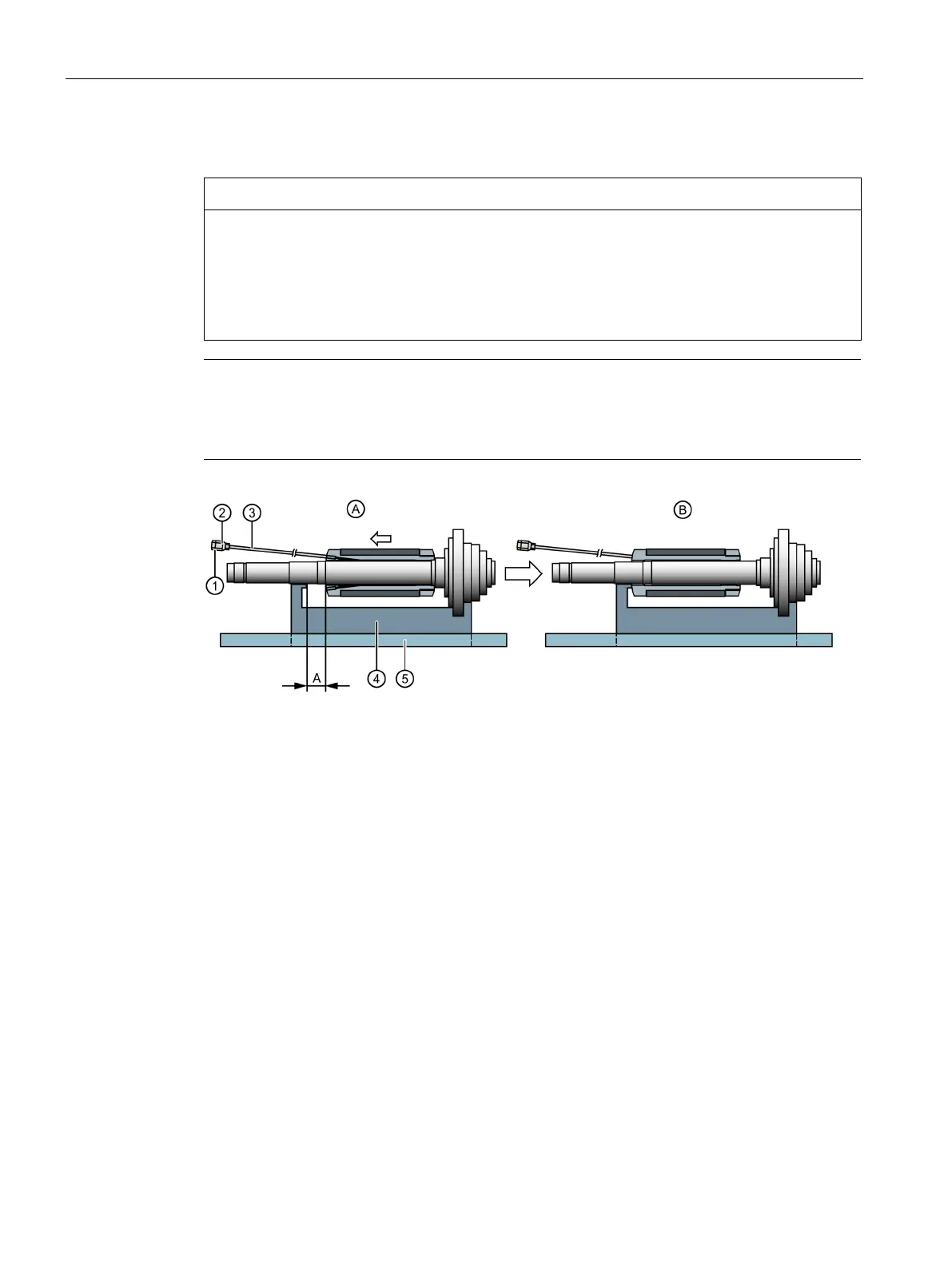

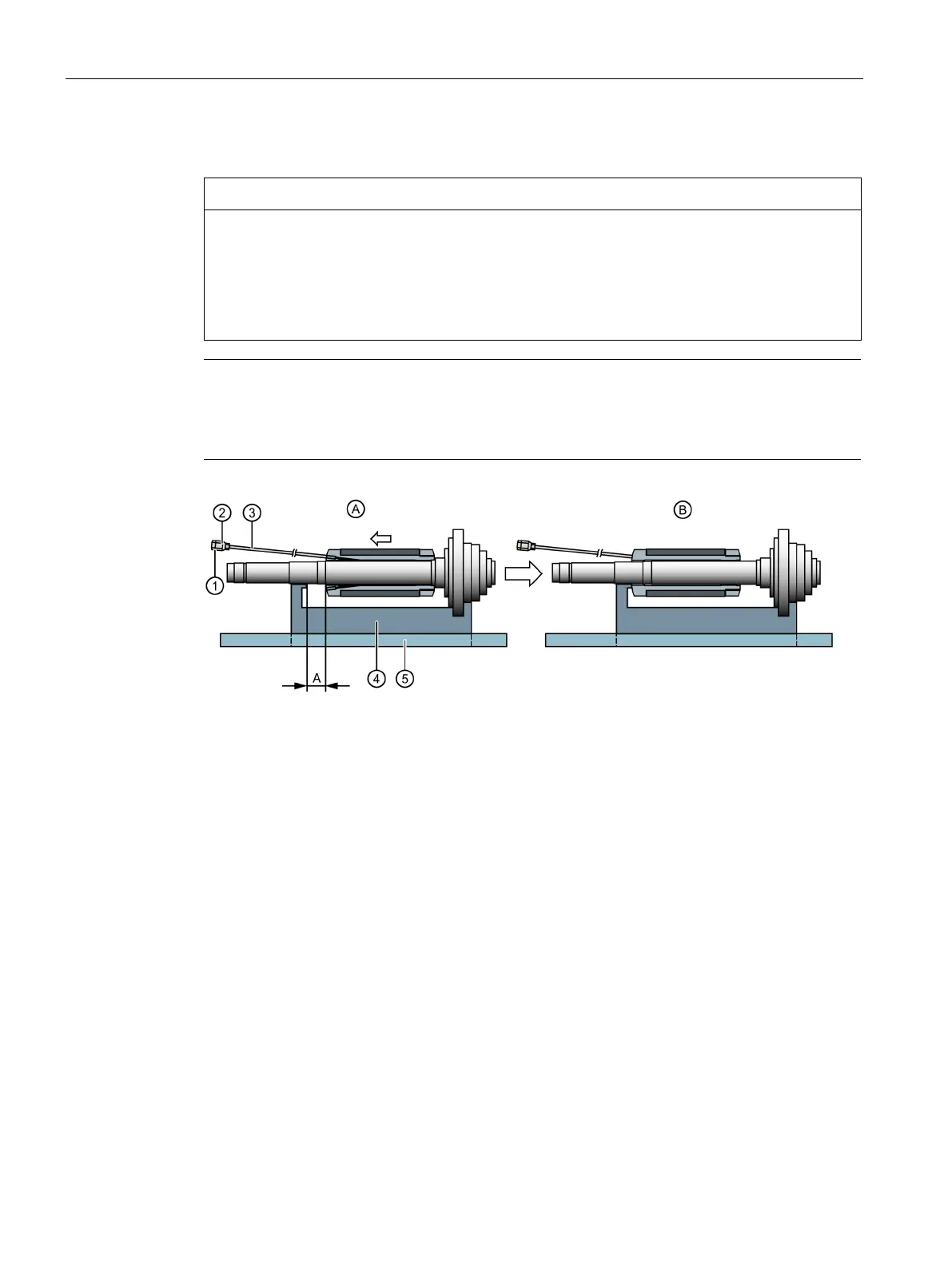

Position of rotor before release

Position of rotor after release

Connection hydraulic hand pump

Supporting fixture (prism)

1)

1)

Dimension for the relative movement = 90 mm for the synchronous version

1)

For synchronous motors made of non-magnetic material

Figure 6-15 Design of equipment for removing the rotor

1. Unscrew both grub screws from the rotor core sleeve.

2. Wrap the threaded shoulder on the extension tube

③ and the second grub screw with

Teflon sealing tape.

3. Screw the extension tube firmly into the sleeve of the rotor core.

4. Place the rotor on the prism

④.

5. Attach the oil hand pump securely to the connection

①.

6. Vent the hydraulic system.

Loading...

Loading...