Motor components, characteristics and options

4.2 Cooling

SIMOTICS M-1FE2 built-in motors

Hardware Installation Manual, 04/2020, A5E50074509B AA

65

4.2.2 Cooling circuit

Note

The electrochemical p

rocesses that take place in a cooling system must be minimized by

choosing the right materials.

Avoid mixed installations (i.e. a combination of different materials, such as copper, brass,

iron, or halogenated plastic (PVC hoses and seals)).

Cool the built-in motor using a semi-open or closed cooling circuit.

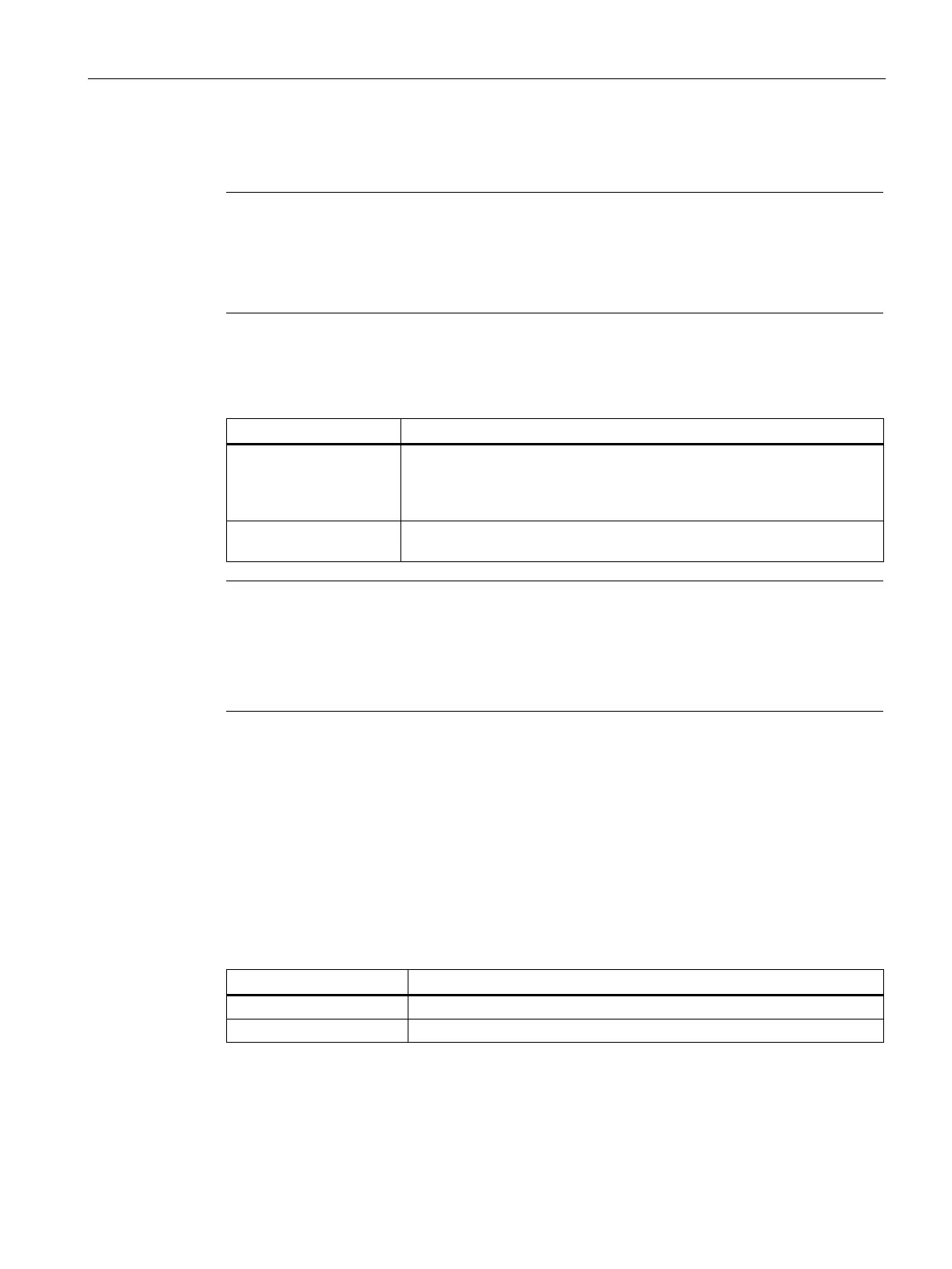

Table 4- 4 Description of the cooling circuits

Closed cooling circuit The pressure equalization tank is closed and possesses an overpressure

valve. Oxygen cannot enter the cooling circuit. The coolant is only routed

through the motors and converters as well as through the components

required to dissipate heat.

Semi-open cooling circuit Contrary to closed cooling circuits, oxygen can enter the coolant through

the pressure equalization tank.

Note

Laying the cooling water pipes

Electrically conductive cooling water pipes must not come into contact with live components.

•

Lay only insulated cooling water pipes or insulate the cooling water pipes subsequently.

Fasten the cooling water pipes mechanically.

All components in the cooling system (motor, heat exchanger, piping system, pump,

pressure equalization tank) must be connected to an equipotential bonding system.

● Install the equipotential bonding properly with a copper busbar or copper strand with the

appropriate cross-section.

Materials used in the motor cooling circuit

● Match the materials in the cooling circuit to the materials in the motor.

Table 4- 5 Materials used in the motor cooling circuit

Steel or aluminum (depending on the type)

O rings FKM (ISO 1629)

Loading...

Loading...