Motor components, characteristics and options

4.2 Cooling

SIMOTICS M-1FE2 built-in motors

66 Hardware Installation Manual, 04/2020, A5E50074509B AA

Materials and components in the cooling circuit

The following table lists a wide variety of materials and components which may or may not

be used in a cooling circuit.

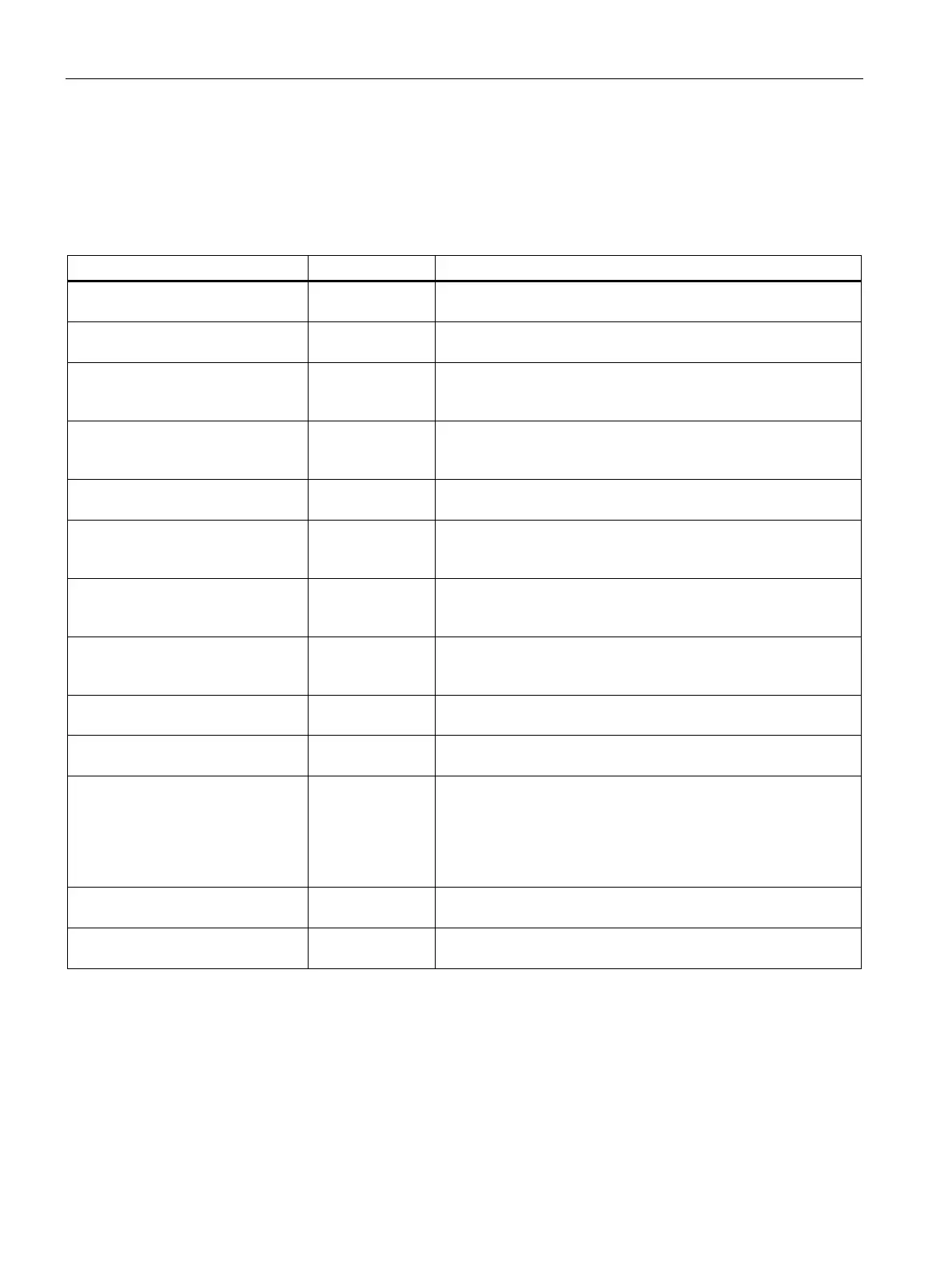

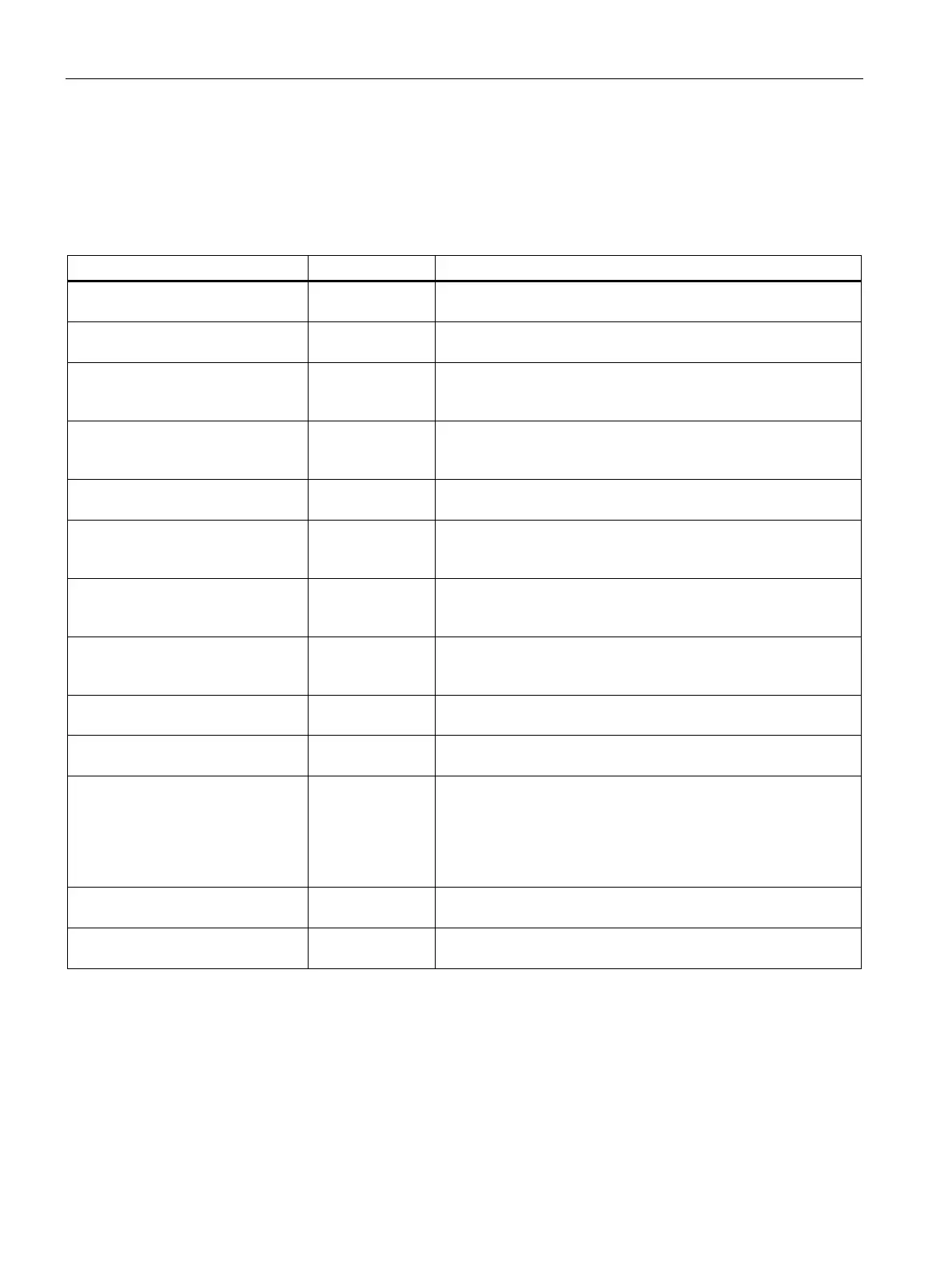

Table 4- 6 Materials and components of a cooling circuit

Zinc Pipes, valves and

Use is not permitted.

Brass Pipes, valves and

Can be used in closed circuits with inhibitor.

Copper Pipes, valves and

fittings

Can be used only in closed circuits with inhibitors in which the

heat sink and copper component are separated (e.g. connection

Common steel (e.g. St37) Pipes Permissible in closed circuits and semi-open circuits with inhibi-

tors or Antifrogen N, check for oxide formation, inspection win-

Cast steel, cast iron Pipes, motors Closed circuit and use of strainers and flushback filters. Fe sepa-

rator for stainless heat sink.

High-alloy steel, Group 1 (V2A) Pipes, valves and

fittings

Can be used for drinking or municipal water with a chloride con-

tent up to <250 ppm, suitable according to definition in Chapter

High-alloy steel, Group 2 (V4A) Pipes, valves and

fittings

Can be used for drinking or municipal water with a chloride con-

tent up to <500 ppm, suitable according to definition in Chapter

ABS (

crylnitrile

utadiene

tyrene) Pipes, valves and

fittings

Suitable according to the definition in Chapter "Coolant defini-

tion". Suitable for mixing with inhibitor and/or biocide as well as

Installation comprising different

materials (mixed installation)

Pipes, valves and

Use is not permitted.

PVC Pipes, valves,

Use is not permitted.

Hoses The use of hoses should be reduced to a minimum (connecting

equipment) and must not be used as the main supply line for the

complete system.

Recommendation: EPDM hoses with an electrical re-

sistance > 10

9

Ω (e.g. Semperflex FKD supplied from Semperit

or DEMITTEL; from PE/EPD, supplied from Telle).

Gaskets Pipes, valves and

The use of FKM, AFM34, EPDM is recommended.

Hose connections Transition

Secure with clips conforming to DIN 2817, available e.g. from the

The following recommendation applies in order to achieve an optimum motor heatsink

(enclosure) lifetime:

● Construct a closed cooling circuit with the cooling unit using stainless steel technology.

The cooling circuit dissipates the heat via a water-water heat exchanger.

● Use for all other components, such as cooling circuit pipes and fittings manufactured of

ABS, stainless steel or general construction steel.

Loading...

Loading...