Description

1.1 System overview

D4x5

Manual, 05/2009

11

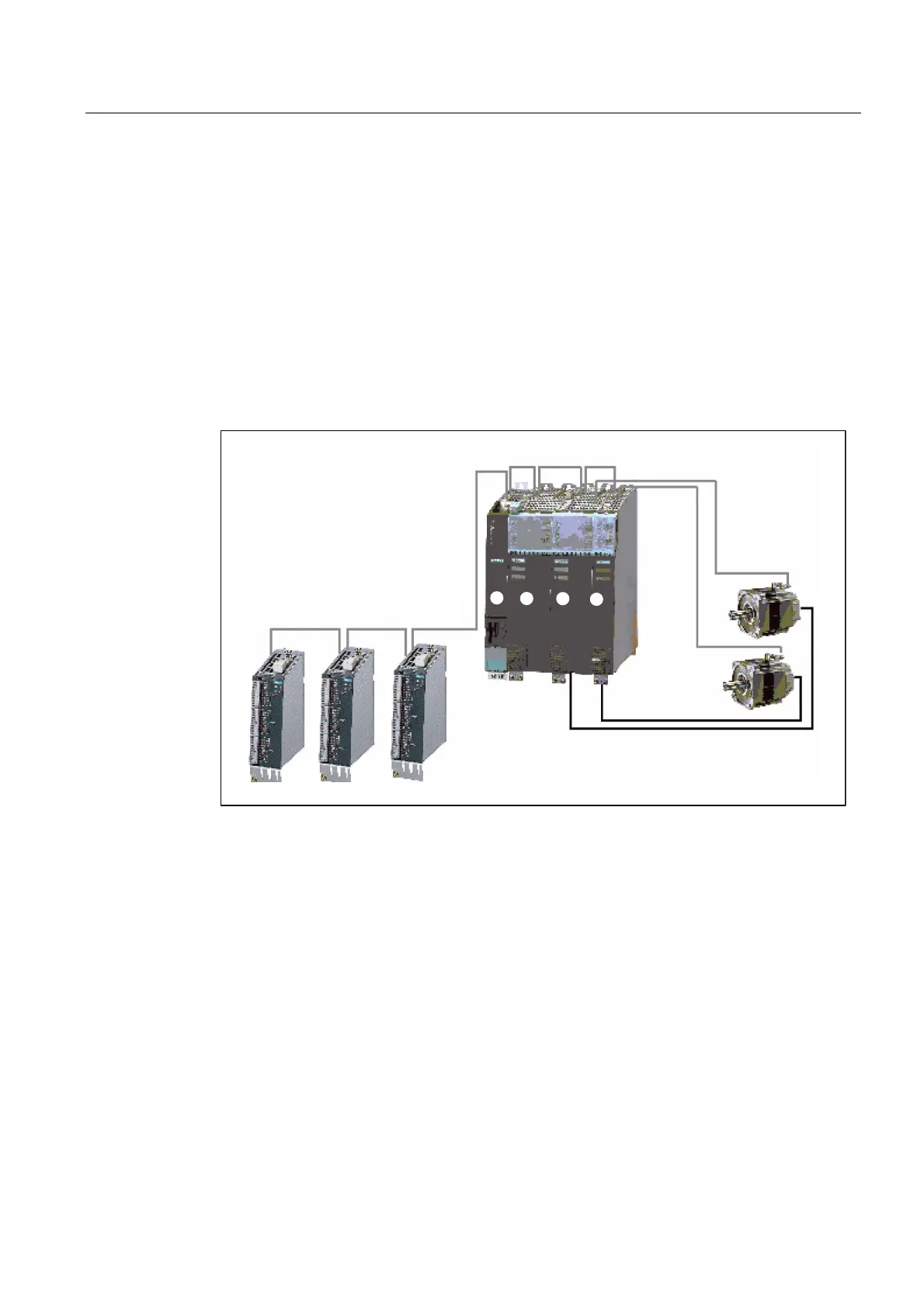

Hardware components: SIMOTION runtime system and SINAMICS drive control

As the central hardware, SIMOTION D uses the SIMOTION D4x5 as a Control Unit

consisting of the SIMOTION runtime system and the SINAMICS drive control. The Control

Unit uses the SINAMICS Integrated drive with various SINAMICS S120 drive modules (Line

and Motor Modules) to perform open-loop and closed-loop control of the axis grouping. A

range of additional SINAMICS S120 components, such as SMx encoder systems or terminal

modules can be connected via DRIVE-CLiQ. With a few exceptions (e.g. no basic positioner

EPos, no Basic Operator Panel BOP20, etc.) the drive control integrated in SIMOTION D

has the same control characteristics and performance features as the SINAMICS S120

CU320 Control Unit. The EPos functionality is provided by the SIMOTION technology

functions. The functionality of SIMOTION D can be expanded with the distributed I/O via

PROFIBUS or with the CBE30 Ethernet Communication Board via PROFINET IO.

The following figure shows a typical SIMOTION D axis grouping.

'5,9(&/L4,2GHYLFHV

7HUPLQDOPRGXOHV

'5,9(&/L4

'5,9(&/L4

3RZHU

ᆰ

ᆱ

ᆲ

ᆲ

ᆳ

ᆳ

Figure 1-1 Example of a SIMOTION D4x5 axis assembly

A SIMOTION D axis grouping generally consists of the following elements:

● SIMOTION D (Control Unit) (1)

This unit contains the programmable runtime system of SIMOTION and the drive software

of SINAMICS S120. In principle, SIMOTION D is capable of controlling multiple

axes/drives.

● One SINAMICS infeed (Line Module) (2)

This module generates a DC link from the supply system.

Loading...

Loading...