3

Programming with ShopMill 10.04

3.5 Contour millin

3

Siemens AG, 2004. All rights reserved

3-194 SINUMERIK 840D/840Di/810D Operation/Programming ShopMill (BAS) – 10.04 Edition

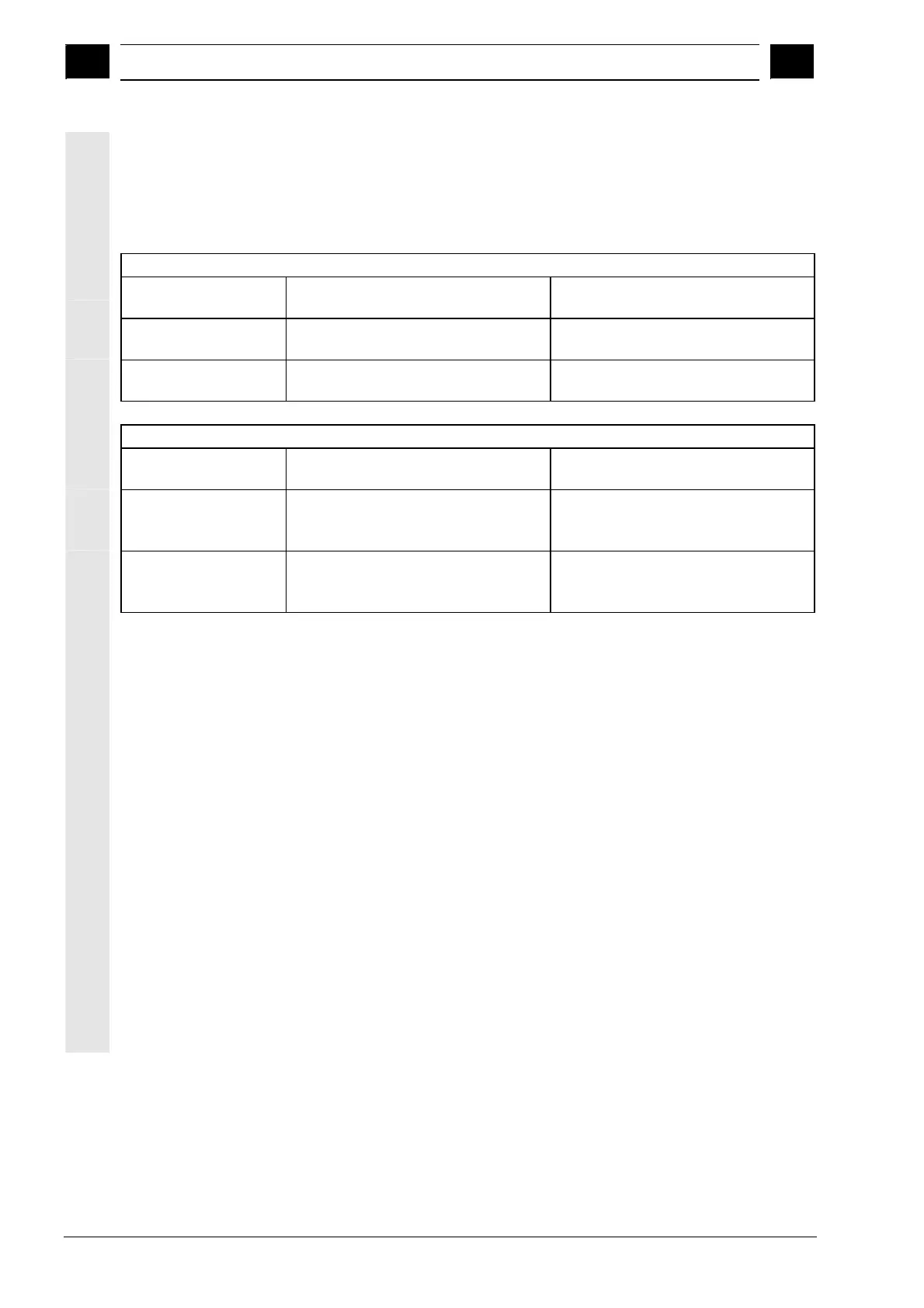

Machining direction

In the case of path milling, the contour is always machined in the

programmed direction. By programming the contour in the clockwise

direction or counterclockwise direction, you can determine whether

the contour is machined with down-cut milling or up-cut milling (see

the following table).

Outside contour

Required direction of

rotation for machining

CW spindle rotation CCW spindle rotation

Down-cut Programming in clockwise direction

CCW cutter radius compensation

Programming in counterclockwise

direction, CW cutter radius compensation

Up-cut Programming in counterclockwise

direction, CW cutter radius compensation

Programming in clockwise direction

CCW cutter radius compensation

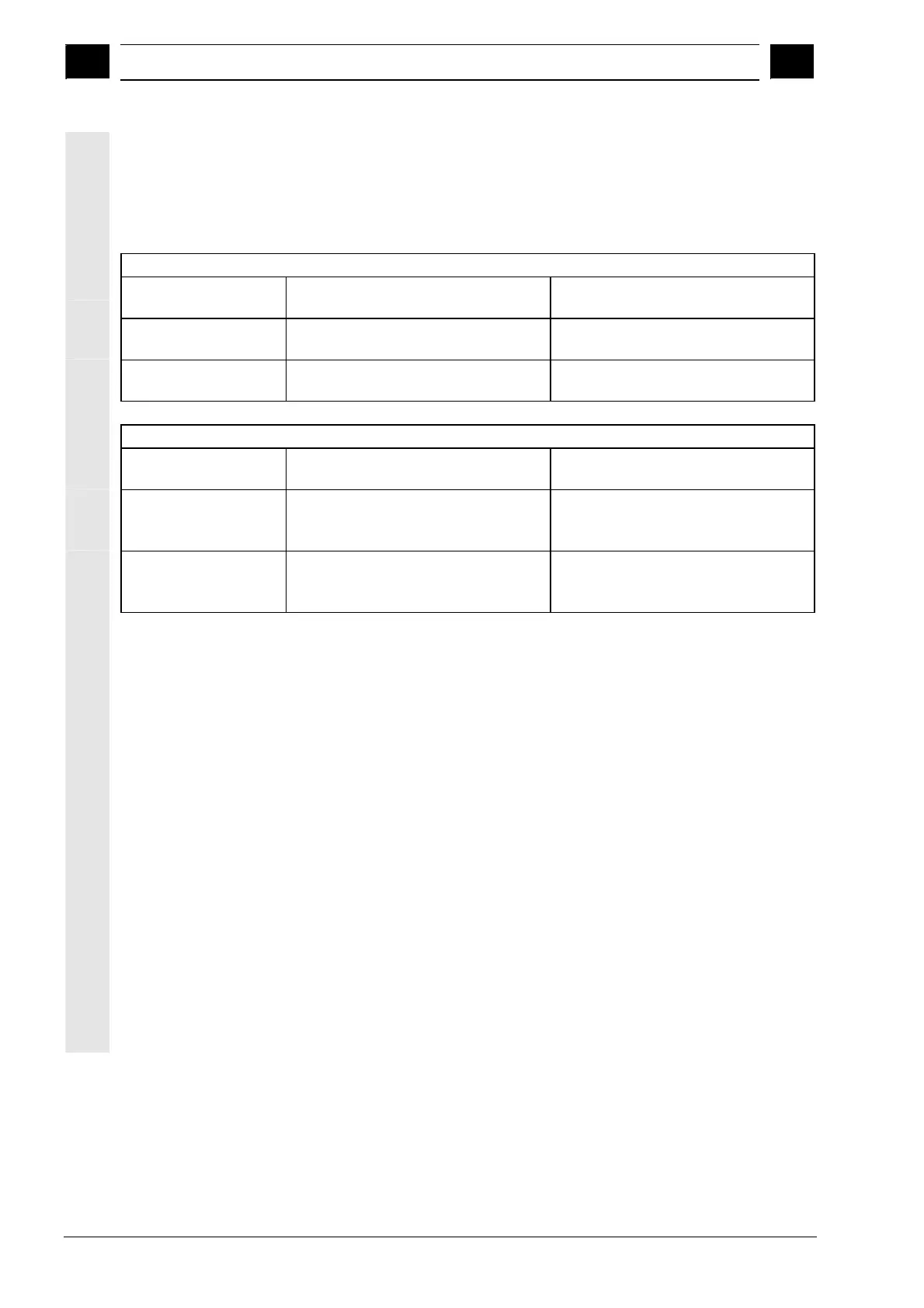

Inside contour

Required direction of

rotation for machining

CW spindle rotation CCW spindle rotation

Down-cut Programming in counterclockwise

direction, CCW cutter radius

compensation

Programming in clockwise direction

CW cutter radius compensation

Up-cut Programming in clockwise direction

CW cutter radius compensation

Programming in counterclockwise

direction, CCW cutter radius

compensation

Contour transition

elements

As a transition between two contour elements, you can choose a

radius or a chamfer. The transition is always appended to the end of a

contour element. The contour transition is selected in the

parameterization screen form of the contour element.

You can use a contour transition element whenever there is an

intersection between two successive elements which can be

calculated from input values. Otherwise you must use the

"Straight/Circle" contour elements.

That means that for a closed counter, you can also program a

transition element from the last to the first element of the contour. The

contour starting point is outside the contour after you have

programmed the transition.

Additional commands

For each contour element, you can enter any additional commands in

G code format. For example, you can program "G9" deceleration,

exact stop for the circle contour element.

You can enter the additional commands (max. 40 characters) in the

extended parameterization screen form ("All parameters" softkey).

Loading...

Loading...