3

Programming with ShopMill 10.04

3.7 Drillin

3

Siemens AG, 2004. All rights reserved

3-232 SINUMERIK 840D/840Di/810D Operation/Programming ShopMill (BAS) – 10.04 Edition

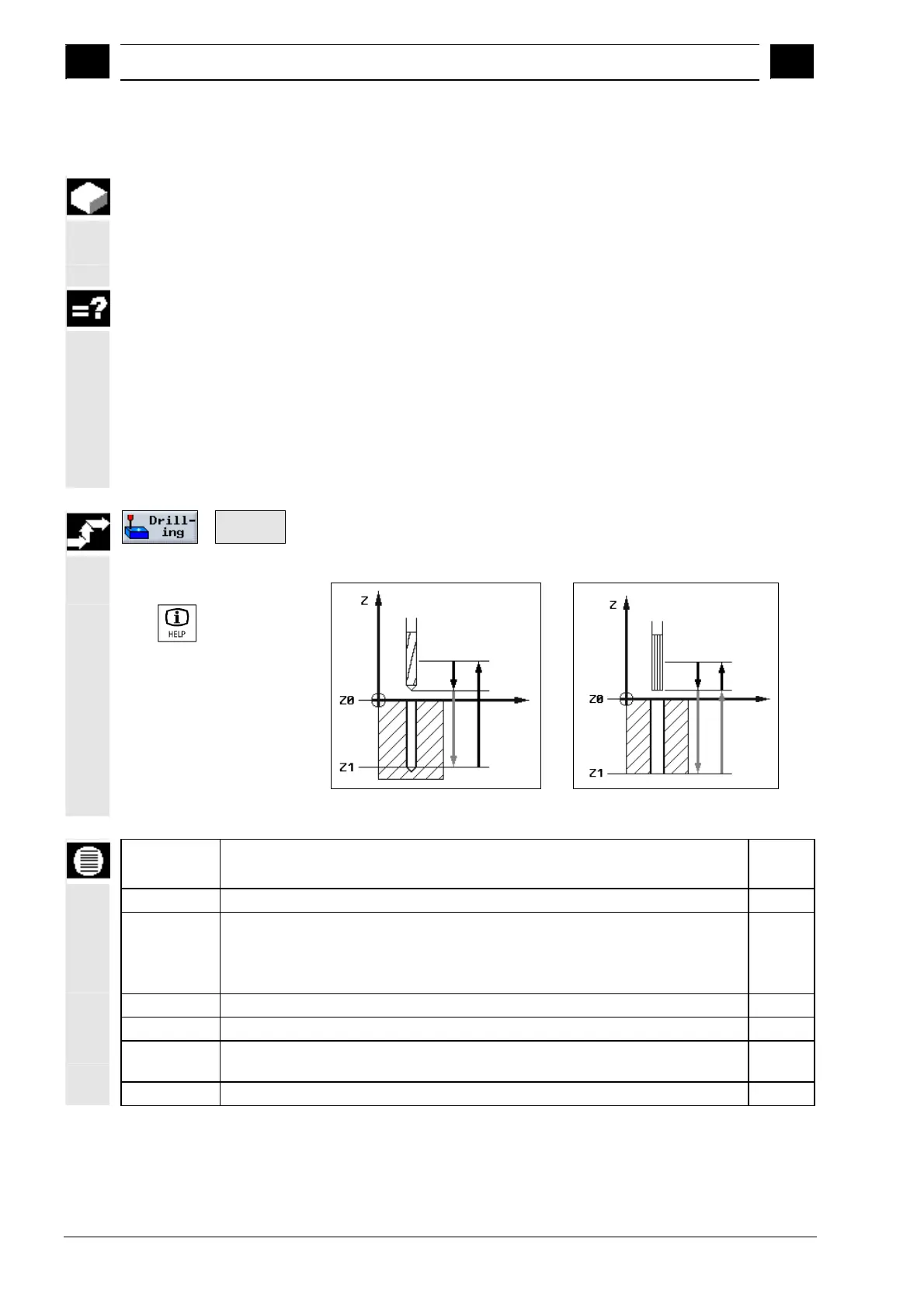

3.7.2 Drilling and reaming

The tool is moved at rapid traverse to the programmed position,

allowing for the retraction plane and safety clearance. It is then

inserted into the workpiece at the feedrate programmed under F until

it reaches depth Z1.

Drilling: If Z1 has been reached and the dwell time expired, the drill is

retracted at rapid traverse either to the retraction plane or the safety

clearance depending on the setting in parameter "Retraction position

pattern". You will find parameter "Retraction position pattern" in the

program header or under "Settings" in the "Miscellaneous" menu.

Reaming: If Z1 has been reached and the dwell time expired, the

reamer is retracted at the programmed retraction feedrate to the

safety clearance.

Drilling

reaming

Press the "Drilling" and "Drilling reaming" softkeys.

Call help display with

the

key

Help display for drilling Help display for reaming

Parameters Description Unit

T, D, F, S, V See Sec. "Programming the tool, offset value and spindle speed".

Shank

Tip

The drill is inserted into the workpiece until the drill shank reaches the value

programmed for Z1. The insertion angle entered in the tool list is applied.

The drill is inserted into the workpiece until the drill tip reaches the value

programmed for Z1 (does not apply in reaming).

Z1 Insertion depth for drill tip or drill shank. mm

Z0 Height of workpiece; Z0 is specified in the position pattern ("Positioning" softkey). mm

DT Dwell time for relief cut. s

rev

FB Retraction feedrate (for reaming only)

Loading...

Loading...