9

10.04 Examples

9.3 Exam

le 3: C

linder surface transformation

9

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Operation/Programming ShopMill (BAS) – 10.04 Edition 9-429

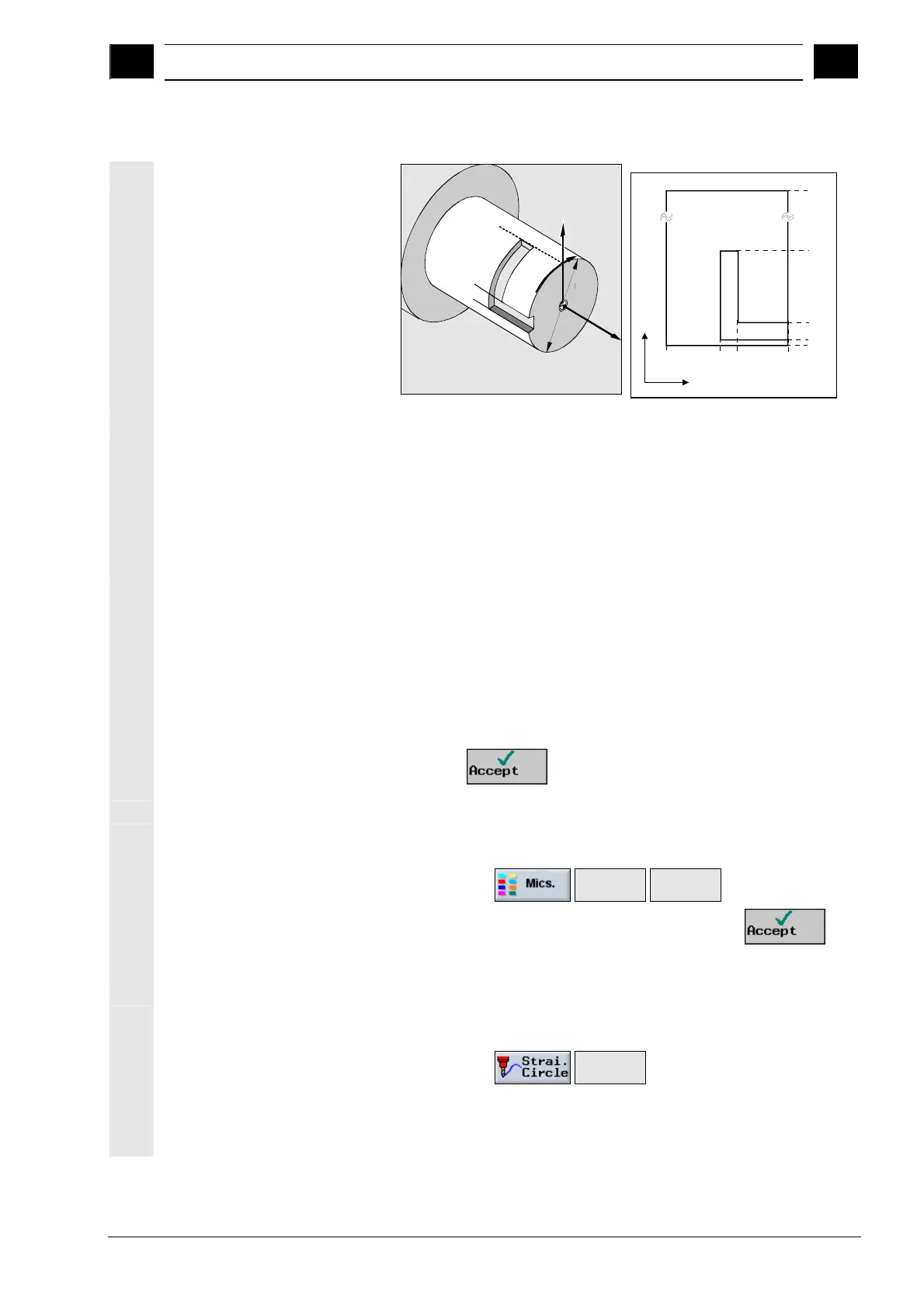

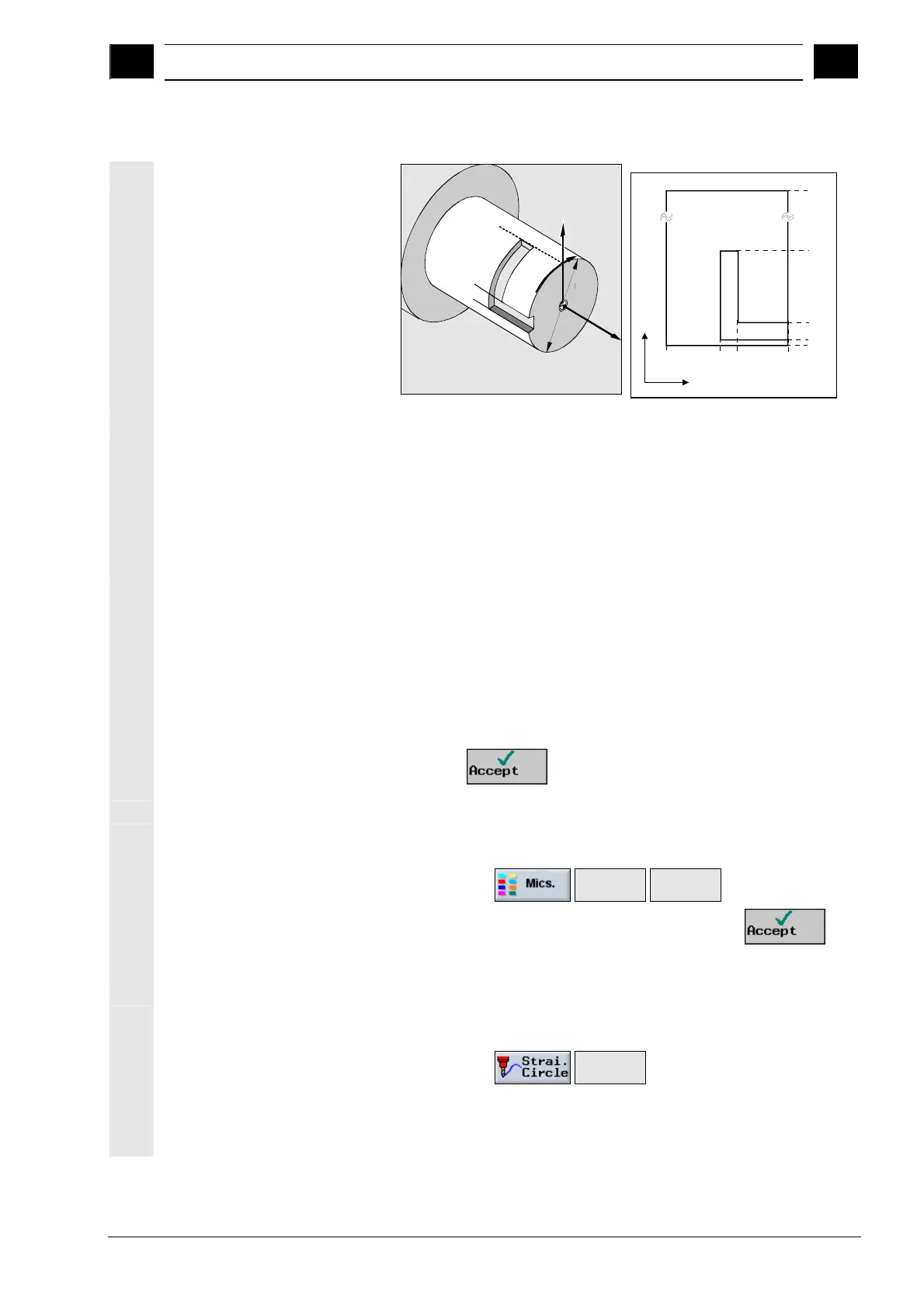

9.3 Example 3: Cylinder surface transformation

Z

Y

X

90°

10°

30°

o80mm

360

o

90

o

30

o

10

o

0

o

0-45-60-100

Y

X

Requirements

• There is a rotary axis, e.g. axis A, and the transformation is

configured via machine data.

• The reference points on the cylinder are predefined.

Program the reference points X0, Y0, Z0 and the required work

offset, for example, in "Machine Manual", "Workpiece zero" and

"Edge". The work offset calculated from these is entered in the

work offset list.

Program

1. Program header

• The blank dimensions correspond to the developed cylinder

peripheral surface (L= ∅ x π).

Define the blank:

X0 0 abs Y0 0 abs Z0 40 abs

X1 -100 abs Y1 251.327 abs Z1 20 abs RP 50

Note: Y1 is calculated from diameter 80 multiplied by π (3.14...)

• Press the

softkey.

2. Activate the work offset in

the program

Select work offset for cylinder surface transformation (e.g. offset the

zero point on the center point of the cylinder end face).

• Select via the

Transfor-

mations>

Work

offset >

softkeys

• Select the required work offset and then press the

softkey.

3. Position the Y axis Position the tool in the Y axis over the center of the cylinder since the

Y axis is not traversed after cylinder surface transformation is

selected.

• Select via the

Straight

line

softkeys

• Enter parameters:

Loading...

Loading...