3

Programming with ShopMill 10.04

3.8 Millin

3

Siemens AG, 2004. All rights reserved

3-274 SINUMERIK 840D/840Di/810D Operation/Programming ShopMill (BAS) – 10.04 Edition

Call help display with

the

key

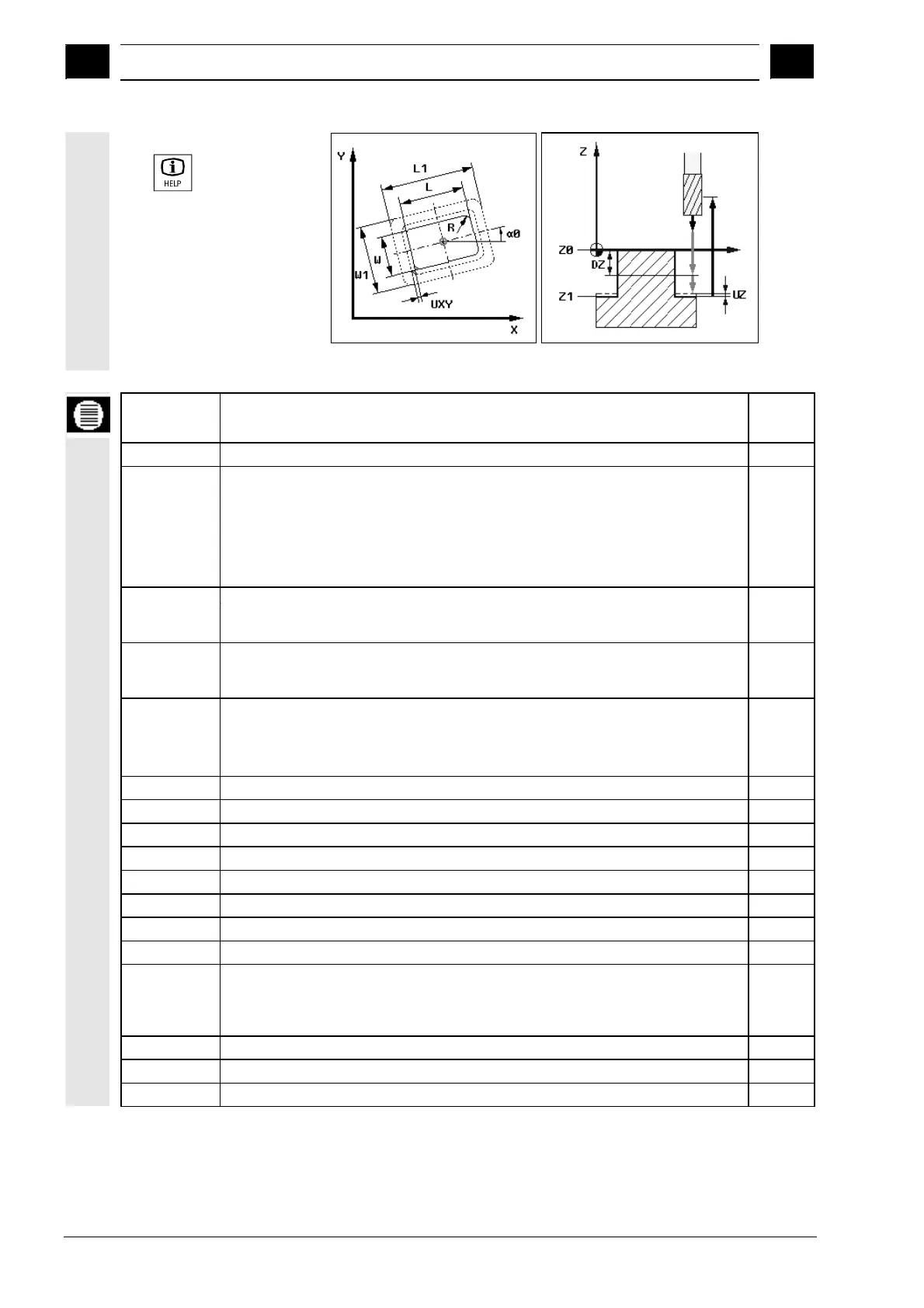

Help displays for milling rectangular spigots

Parameters Description Unit

T, F, S, V See Sec. "Programming the tool, offset value and spindle speed".

Reference

point

You can select 5 different reference points:

• Spigot center

• Bottom left

• Bottom right

• Top left

• Top right

Machining type Roughing

Finishing

Chamfer

Single pos.

Pos. pattern

rectangular spigot is machined at the programmed position (X0, Y0, Z0).

Several rectangular spigots are machined in a position pattern (e.g. full circle, pitch

circle, matrix, etc.).

X0

Y0

Z0

The positions refer to the reference point:

Position in X direction (single position only), abs. or inc.

Position in Y direction (single position only), abs. or inc.

Workpiece height (single position only), abs. or inc.

mm

mm

mm

W Width of spigot after machining mm

L Length of spigot after machining mm

R Radius at edges of spigot (corner radius) mm

α0

ngle of rotation Degr.

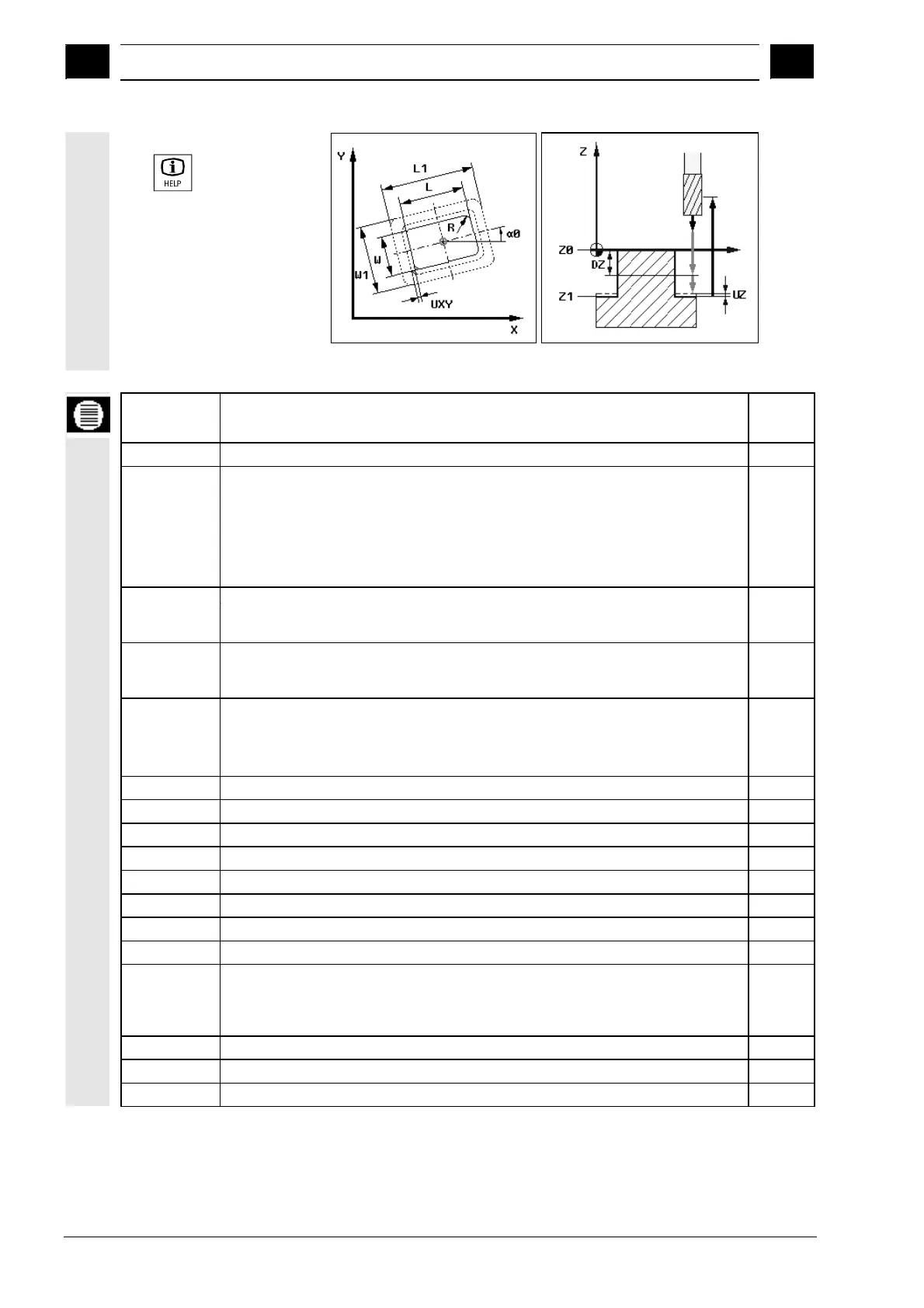

Z1 Depth of spigot (abs. or inc.) (not for chamfer) mm

DZ Max. depth infeed (Z direction) (not for chamfer) mm

FS

Chamfer width (for chamfer only), inc.

mm

ZFS

Insertion depth tool tip (for chamfer only), abs. or inc.

mm

UXY Finishing allowance in the plane in relation to length (L) and width (W) of the spigot;

Smaller spigot dimensions are obtained by calling the cycle again and programming

it with a lower finishing allowance.

(not for chamfer)

mm

UZ Finishing allowance in depth (tool axis) (not for chamfer) mm

W1 Width of specified blank spigot (important for determining approach position) mm

L1 Length of specified blank spigot (important for determining approach position) mm

Loading...

Loading...