1

10.04 Introduction

1.3 User interface

1

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Operation/Programming ShopMill (BAS) – 10.04 Edition 1-39

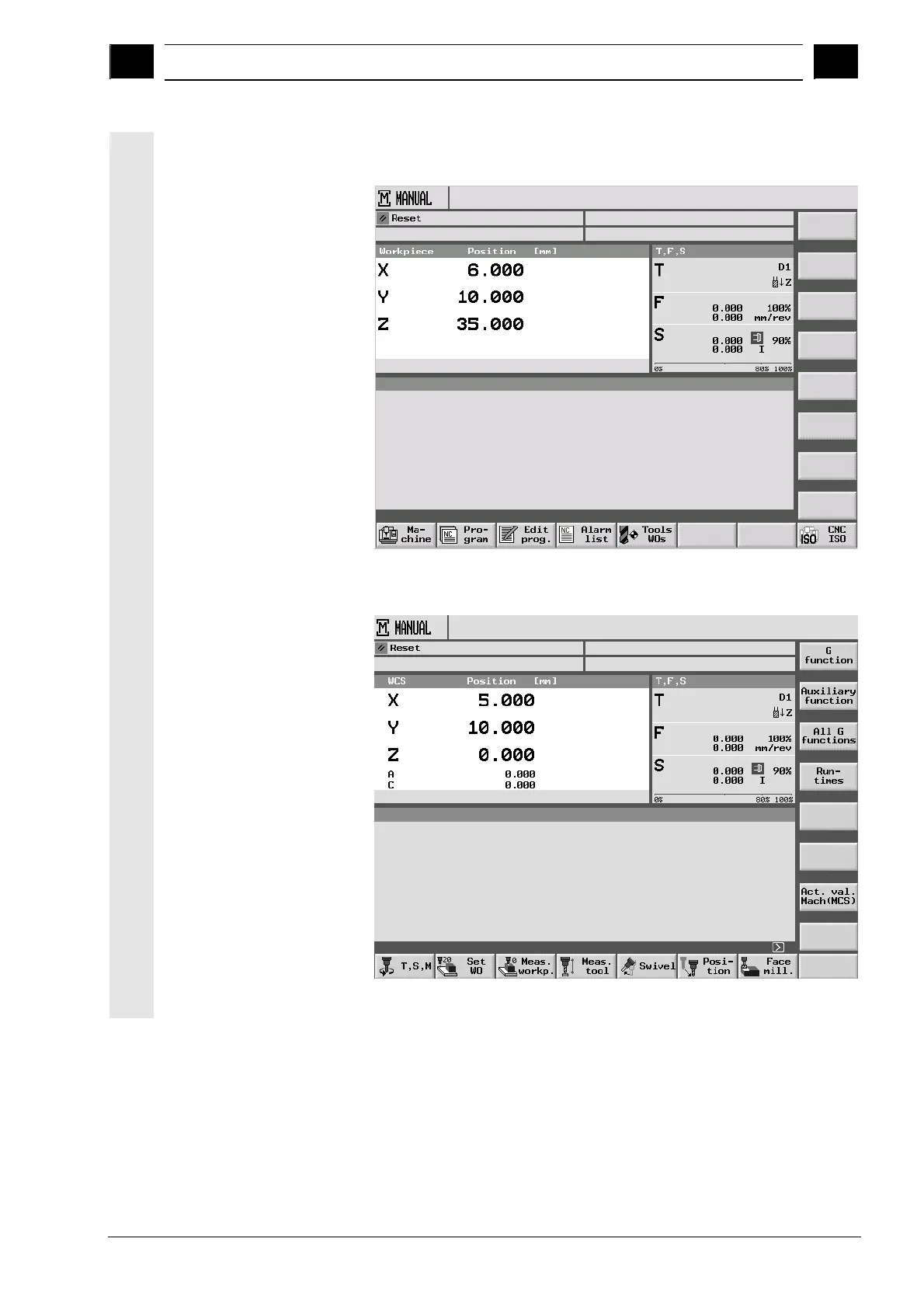

If you select another operating mode or operating area, the horizontal

and vertical softkey bars change.

Main menu

4

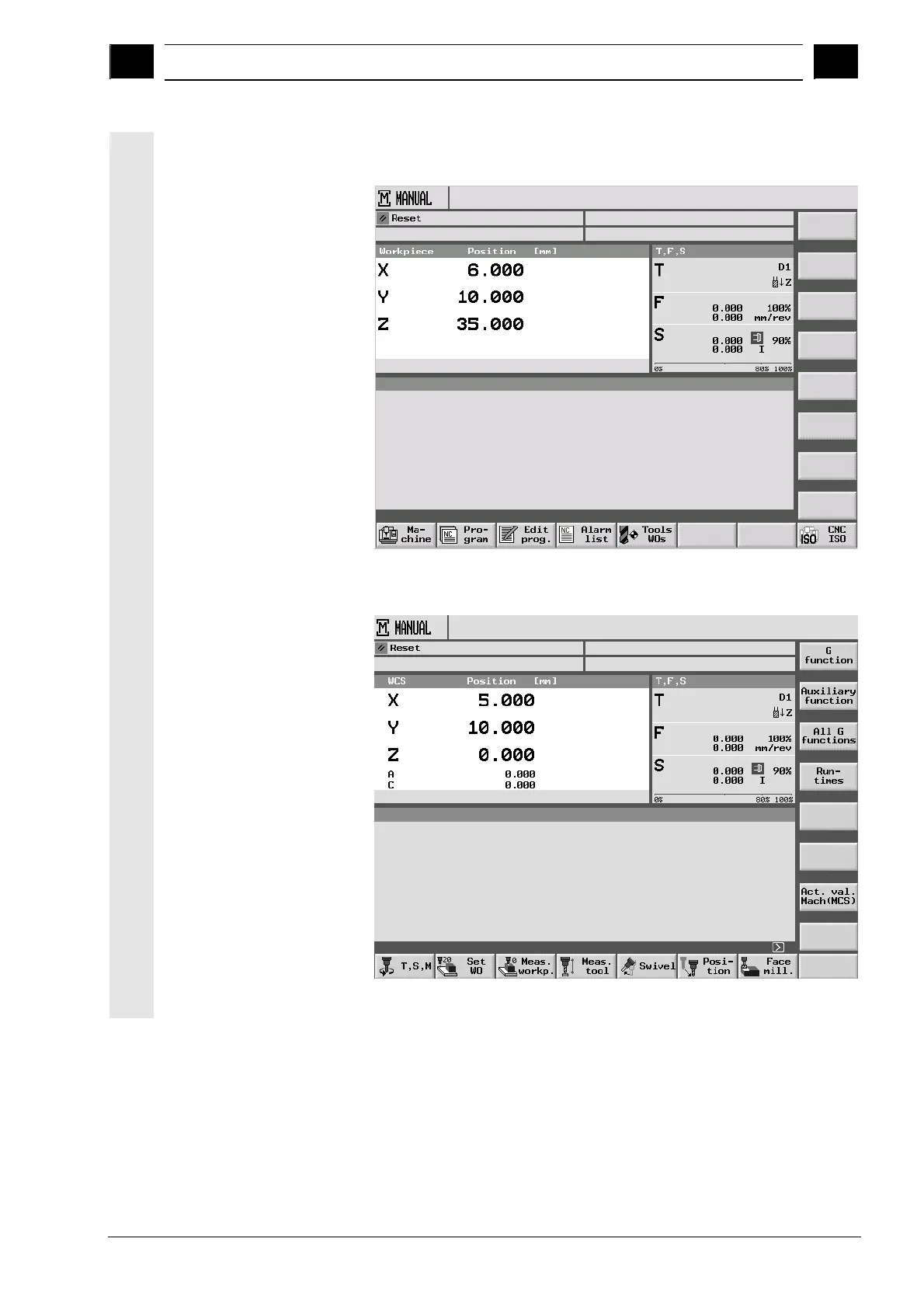

Machine Manual operating mode

Loading...

Loading...