6 Assi

nin

Parameters to the Control and the PLC Pro

ram

6

03.96

6.9 Axes and spindles

6-108

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

6.9 Axes and spindles

6.9.1 Description of the axis configuration

The SINUMERIK 840D is supplied as standard with the following configuration:

S NCU 571: 1 channel and 5 axes.

S NCU 572/573: 2 channels and 8 axes with simulated setpoint or

actual value channel.

> 2 channels are provided on the SINUMERIK 840D.

Machine axes are all axes existing on the machine. They are defined as geom-

etry axes or additional axes.

The workpiece geometry is programmed with the geometry axes. The geometry

axes form a rectangular coordinate system (2D or 3D).

In contrast to geometry axes, there is no geometric relationship between special

axes such as:

– rotary axes

– turret axes

– position-controlled spindles

The axis configuration is defined on 3 levels:

1. Machine level

2. Channel level

3. Program level

MD 10000: AXCONF_MACHAX_NAME_TAB

An axis name is defined here for each machine axis in

MD 10000: AXCONF_MACHAX_NAME_TAB.

Example:

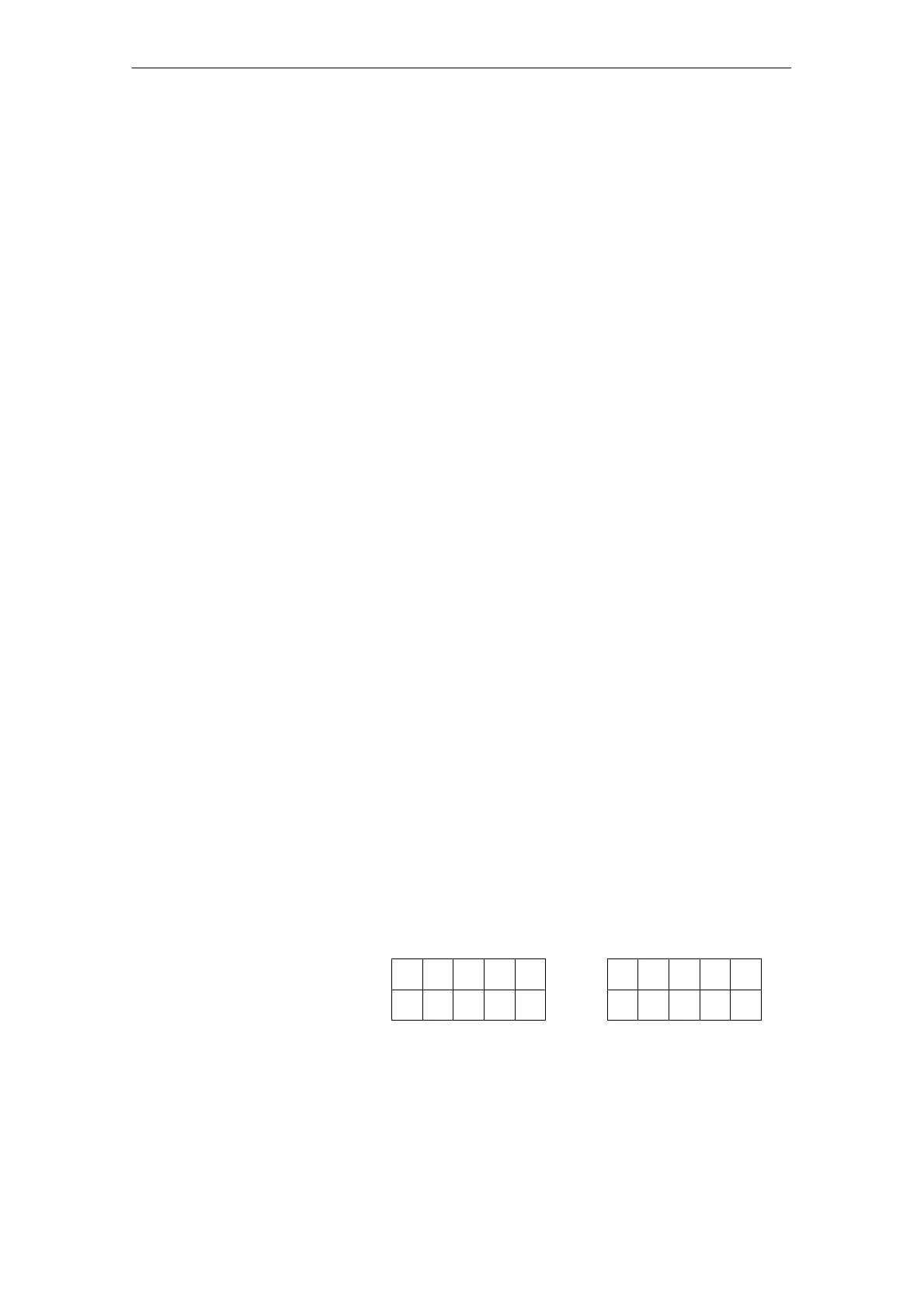

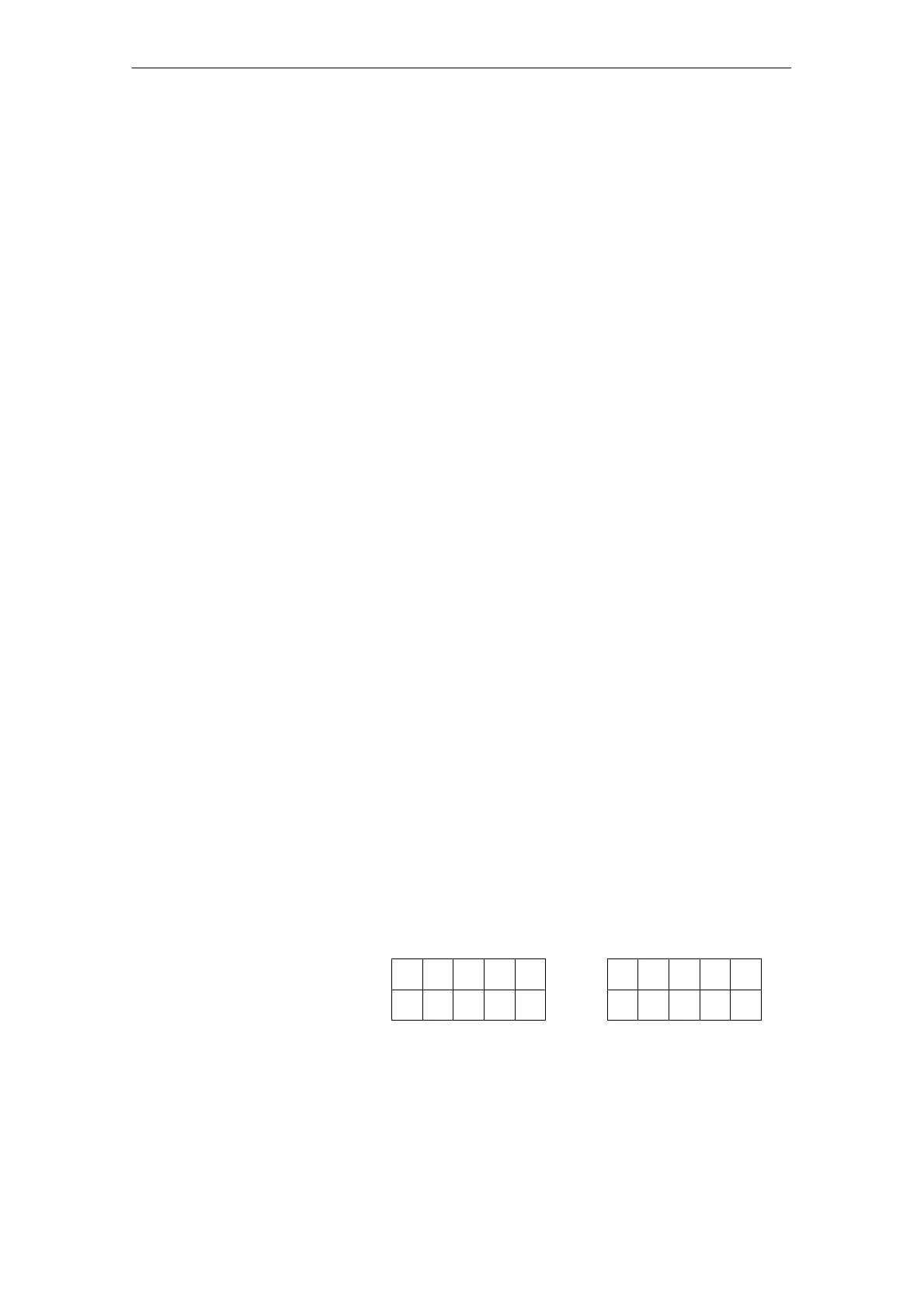

Turning machine Milling machine

with X, Z, C axis/spindle 4 axes + spindle/C axis

X1

01

Z1 C1

342

X1

01

Y1 Z1

342

A1 C1

MD 10000

Index

Number of

channels

Machine axes

Geometry axes

Special axes

Axis configuration

1. Machine level

Loading...

Loading...