6 Assi

nin

Parameters to the Control and the PLC Pro

ram

6

03.96

6.9 Axes and spindles

6-128

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

In the case of the machine data with the “Control parameter set no.” field

parameter, the first field is used for normal axis operation. In the case of

interpolations which include one spindle, e.g. with G331 (tapping without

compensating chuck), the selected gear stage determines the appropriate field

of the axes involved (1st gear stage –––> field index 1). This applies to all

machine axes which can be traversed via geometry axes. See Section 6.9.2.

In the case of axes which interpolate with a spindle during thread cutting opera-

tions (G33, G331, G332), the machine data with indices [1]...[5] must also be

supplied with appropriate values.

All existing gear stages must be parameterized for rotary axes that are to be

operated as a spindle with gear stage change (indices [1]...[5]).

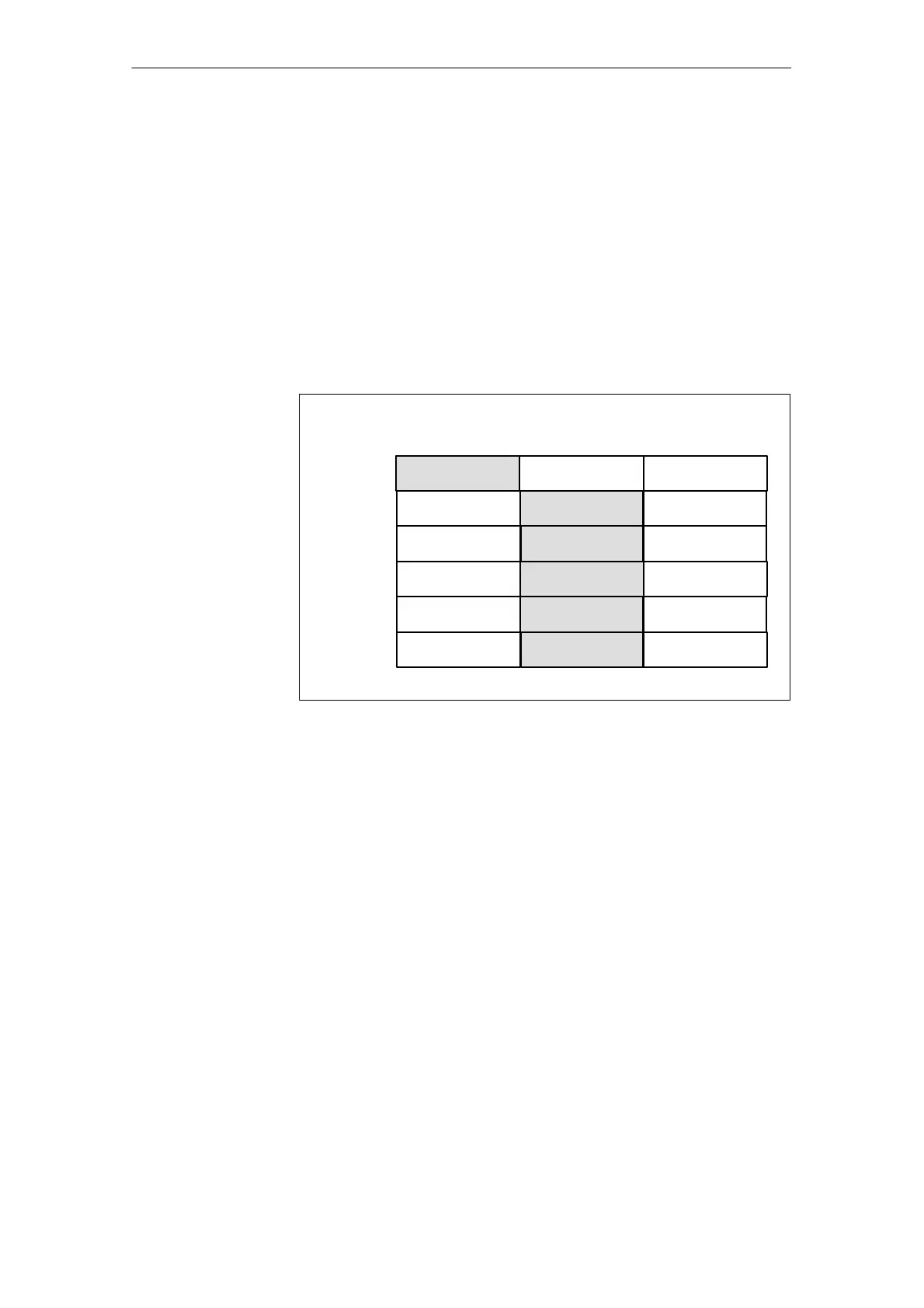

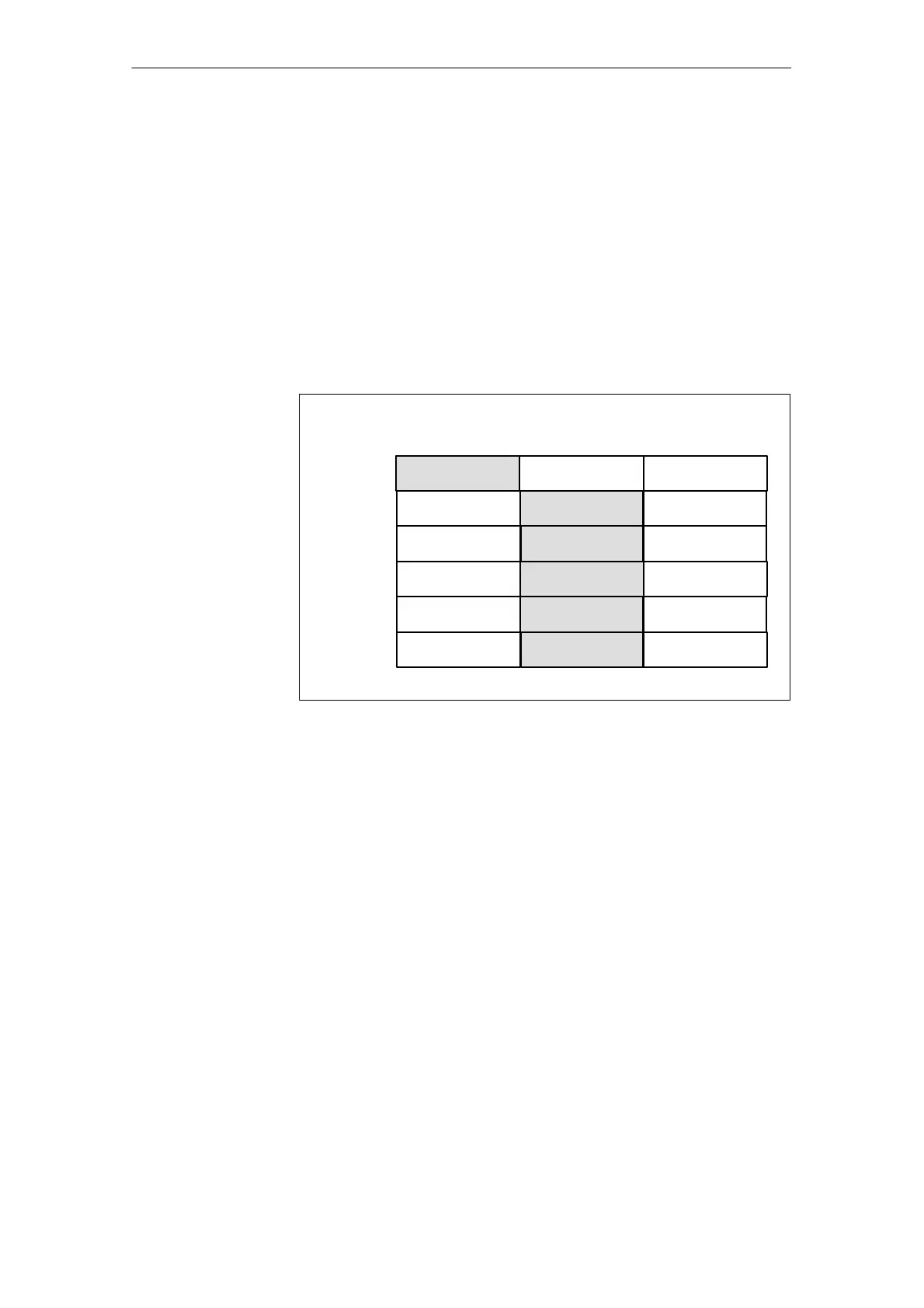

Parameter set

1

2

3

4

5

0

Default

Spindle in

axis mode

Axis interpolates

with spindle (G33)

Axis interpolates

with spindle (G33)

Axis interpolates

with spindle (G33)

Axis interpolates

with spindle (G33)

Axis interpolates

with spindle (G33)

Spindle mode

Spindle mode

Spindle mode

Spindle mode

Spindle mode

1st

3rd

2nd

4th

5th

As specified by

manufacturer

Spindle gear stage

Axis Spindle

Fig. 6-15 Validity of parameter sets in axis and spindle modes

MD 31050: DRIVE_AX_RATIO_DENOM (denominator load gearing)

MD 31060: DRIVE_AX_RATIO_NUMERA (numerator load gearing)

MD 32200: POSCTRL_GAIN (K

V

factor)

MD 32800: EQUIV_CURRCTRL_TIME (substitute time constant, current control

loop for feedforward control)

MD 32810: EQUIV_SPEEDCTRL_TIME (substitute time constant, speed

control loop for feedforward control)

MD 32910: DYN_MATCH_TIME (dynamic response matching time constant)

MD 36200: AX_VELO_LIMIT (threshold value for speed monitoring)

MD 32200: POSCTRL_GAIN [0,Z1] = 1 (K

V

for normal axis operation)

MD 32200: POSCTRL_GAIN [1,Z1] = 1 (K

V

for G331, spindle gear stage 1)

MD 32200: POSCTRL_GAIN [3,Z1] = 1 (K

V

for G331, spindle gear stage)

MD 32200: POSCTRL_GAIN [0,X1] = 1 (K

V

for normal axis operation)

MD 32200: POSCTRL_GAIN [1,X1] = 1 (K

V

for G331, spindle gear stage 1)

MD 32200: POSCTRL_GAIN [3,X1] = 1 (K

V

for G331, spindle gear stage 3)

Parameter sets

Axis

Spindle

Example

Loading...

Loading...