System overview

1.9 Connection

SIRIUS Innovations

84 System Manual, 01/2011, A8E56203870002-03

1.9.2.3 Conductor cross-sections for ring cable lug connection system

Conductor cross-sections for ring cable lug connection system

The tables below define the permissible conductor cross-sections for main terminals and

auxiliary conductor connections in sizes S00 and S0 for ring cable lug connection systems.

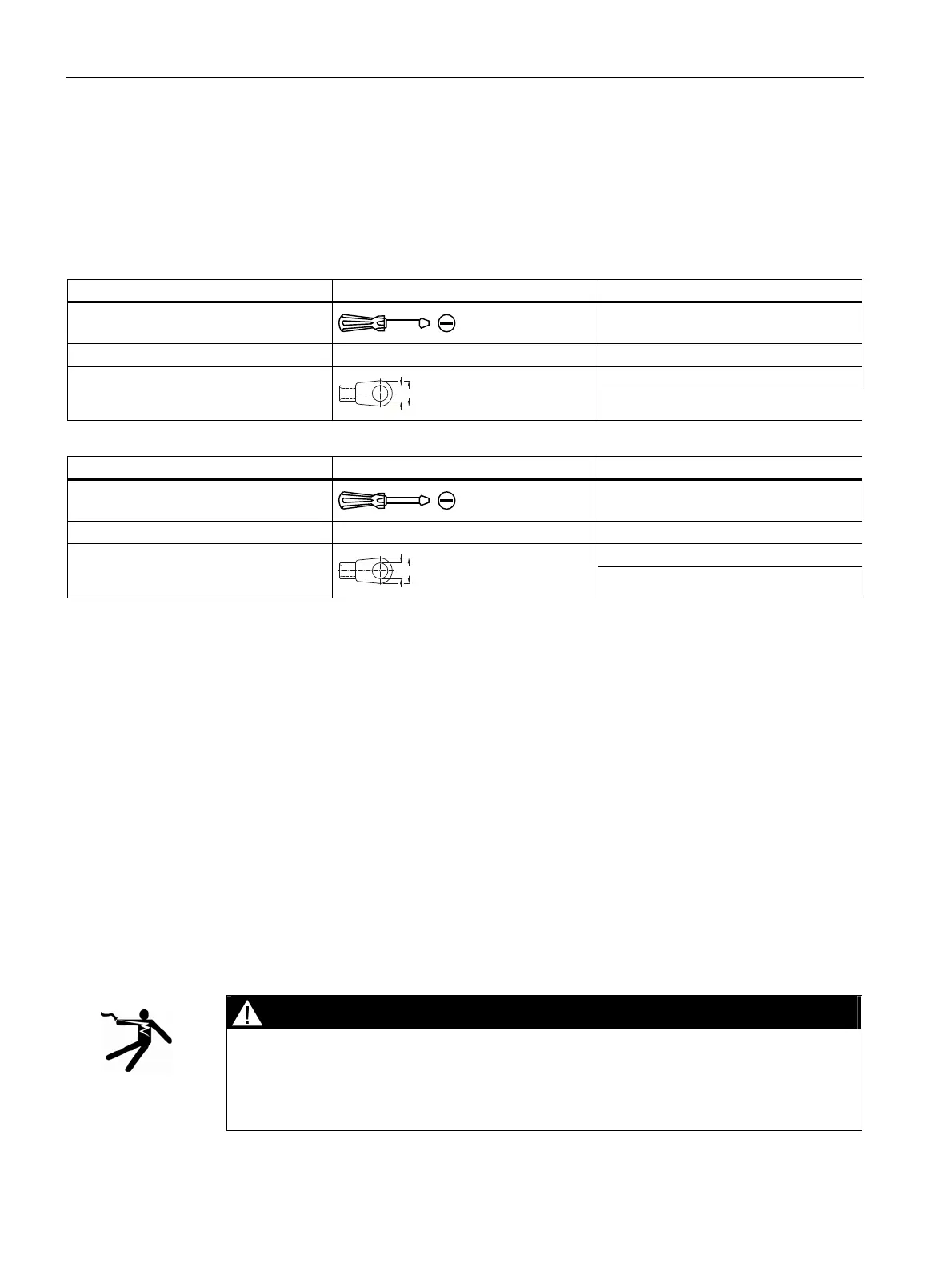

Table 1- 34 Main conductors and auxiliary conductors of size S00 with M3 combination screws

SIRIUS devices

Tool

Pozidriv size 2,

Ø 5 to 6 mm

Tightening torque 0.8 to 1.2 Nm

d

2

= min. 3.2 mm Ring cable lug

1)

d

2

d

3

d

3

= max. 7.5 mm

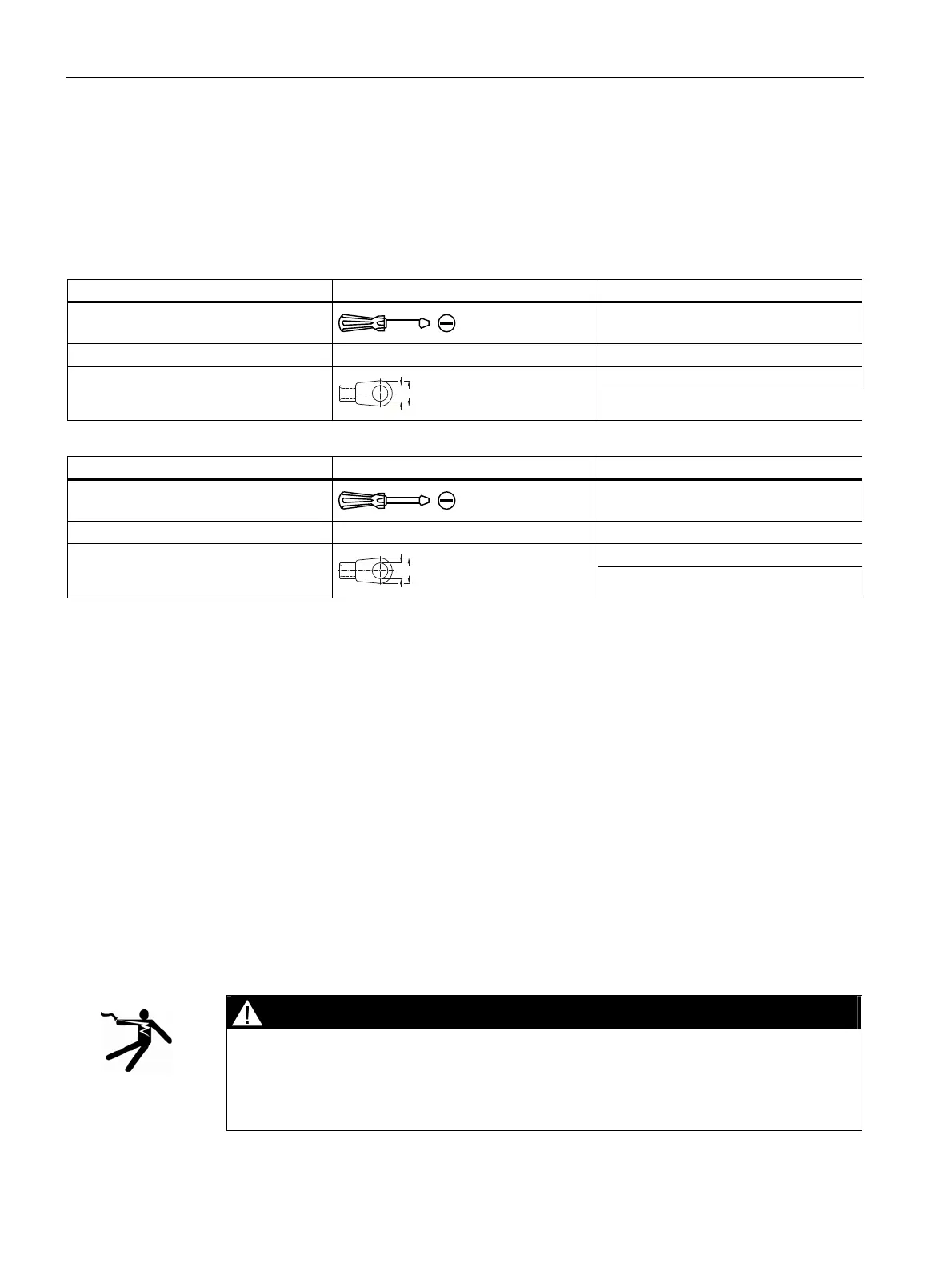

Table 1- 35 Main conductors and auxiliary conductors of size S0 with M4 combination screws

SIRIUS devices

Tool

Pozidriv size 2,

Ø 5 to 6 mm

Tightening torque 2.0 to 2.5 Nm

d

2

= min. 4.3 mm Ring cable lug

1)

d

2

d

3

d

3

= max. 12.2 mm

1)

The following ring cable lugs are approved for achieving the required clearances and creepage distances:

● For applications according to IEC 60947-1:

– DIN 46237 (with insulating sleeve)

– JIS CS805 type RAV (with insulating sleeve)

– JIS CS805 type RAP (with insulating sleeve)

● For applications according to UL 508:

– DIN 46 234 (without insulating sleeve)

– DIN 46225 (without insulating sleeve)

– JIS CS805 (without insulating sleeve)

A shrink-on sleeve must be used to insulate ring cable lugs without an insulating sleeve. The following

conditions must be met:

● Application temperature: -55 °C to +155 °C

● UL 224 approved

● Flame-protected

DANGER

Hazardous voltage.

Will cause death or serious injury.

Only use approved ring cable lugs to meet the required clearances and creepage

distances.

Loading...

Loading...