4. Assembly instructions Page 27

4.5. Installation of pump elements

Danger!

The piston pump unit must be de-

energized before installation or removal of

a pump element. Performing work on an

energized pump or product may result in

serious injury or death. Assembly,

maintenance, and repair work may only be

performed on products that have been de-

energized by qualified technical personnel.

The supply voltage must be switched off

before opening any of the product's

components.

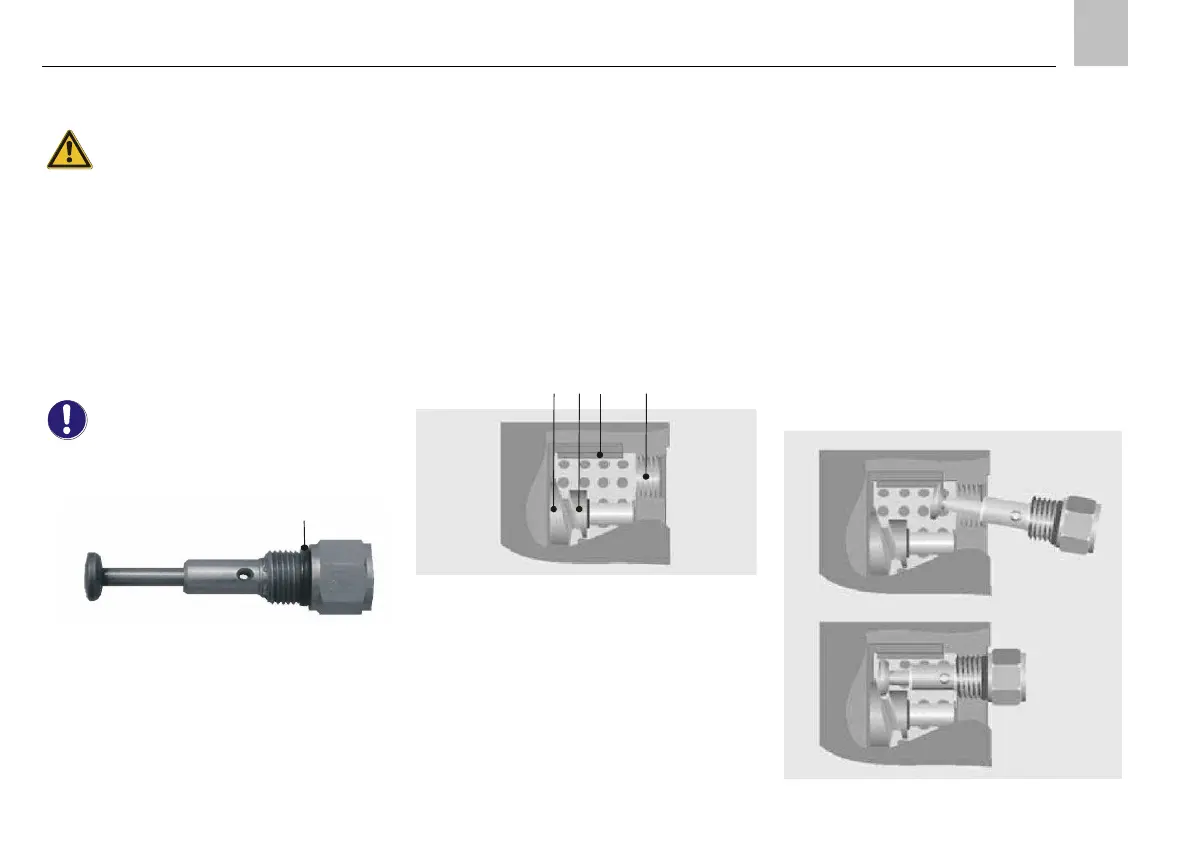

The pump elements are fitted only with O-

ring 15.4x2.1 (1) without any additional

sealing ring.

Fig.25. Pump element with O-ring (item 1)

Install the pump elements as follows:

Step 1:

Remove screw plug (if present).

Step 2:

Remove bothersome lubricant between the internal

thread, guide slot in the strainer ring and the groove

between the cam disc and return disc with a suitable

tool.

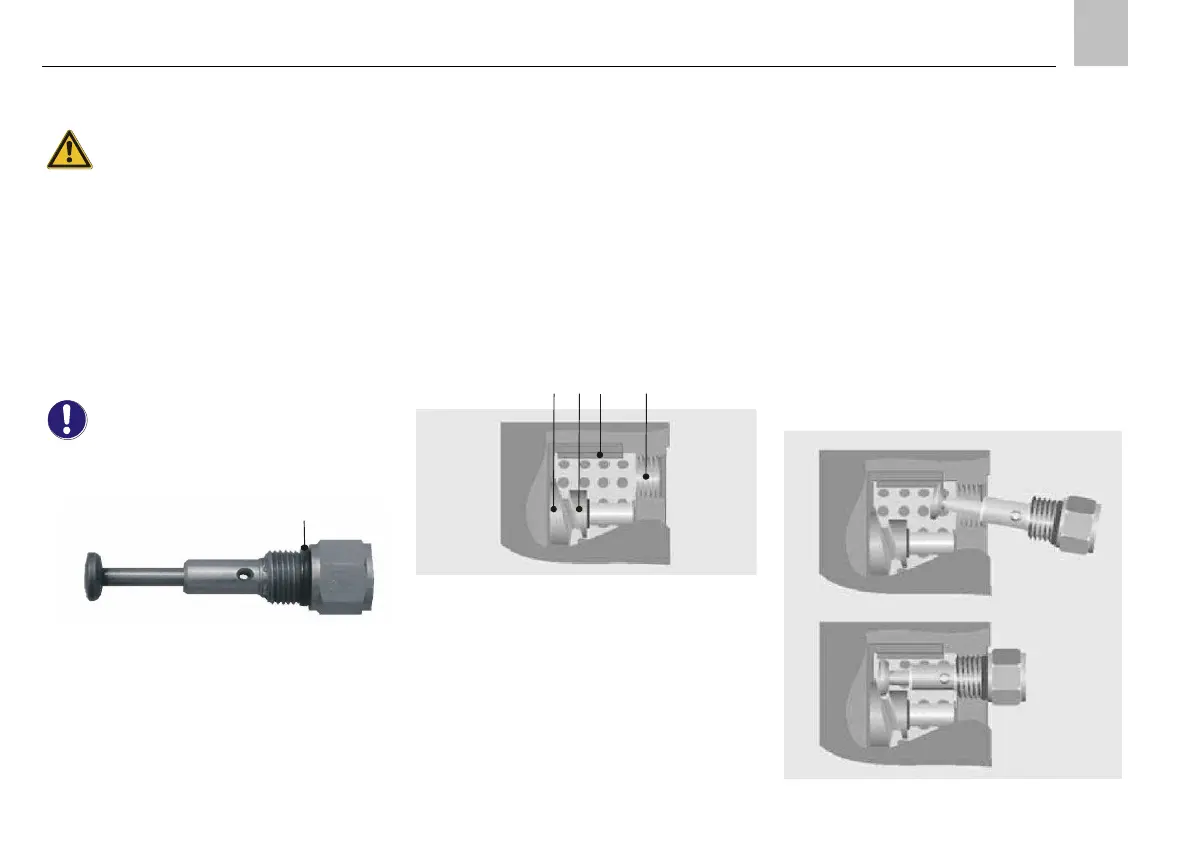

Fig.26. Sectional top view of pump housing

1 Internal thread

2 Guide slot in strainer ring

3 Cam disc

4 Return disc

Step 3:

Pull piston of the pump element as far as possible

out of the element, and insert it along the guide slot

of the strainer ring between the cam disc and return

disc ( Fig.27). If the pump element has not been

correctly installed, it is not possible to tighten the

thread.

Close any outlets which are not required with a

screw plug according to DIN 910-M18x1.5-5.8 with

sealing ring according to DIN 7603-A18x24-Al.

Fig.27. Inserting the pump element

Loading...

Loading...