Page 26

EN

4.5.2.3 Fill level monitoring

Type: W1 (max. 24 VDC)

for NLGI Grade 2 greases

Technical data

Fill level monitoring W1

Function ............... mechanical, via

floating

reed contact

Form of contact ..........NO-contact

Switching capacity, max. ...0.6 W

Switching voltage, max. ... 24 VDC

Switched current, max. ... 25 mA;

only ohm load

1

)

Plug-in connection DIN EN 60947/IEC 947

Connection diagram ......7-pin round plug

2

)

1) No inductive load, no lamp load (signal lamp)

2) Socket-see Accessories

Page 28

Functional description

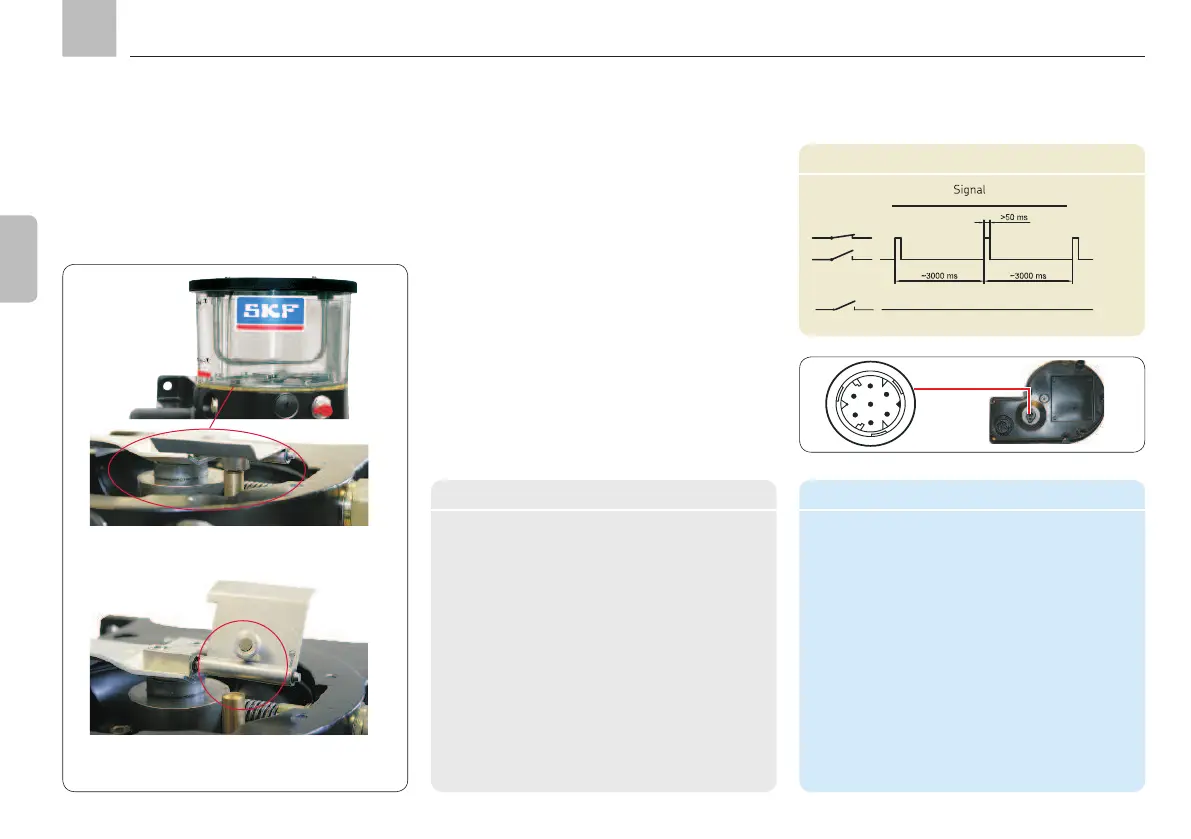

The W1 fill level switch is designed as a rocker

switch and is integrated in the bottom of the

reservoir. A magnetic rocker mounted on the

agitator is turned downward by the grease re-

sistance when the reservoir is full. A pulse is

created at each revolution of the agitator.

When the minimum fill level is reached, the

resistance the grease exerts on the rocker

subsides. The rocker turns back and the pulses

are interrupted.

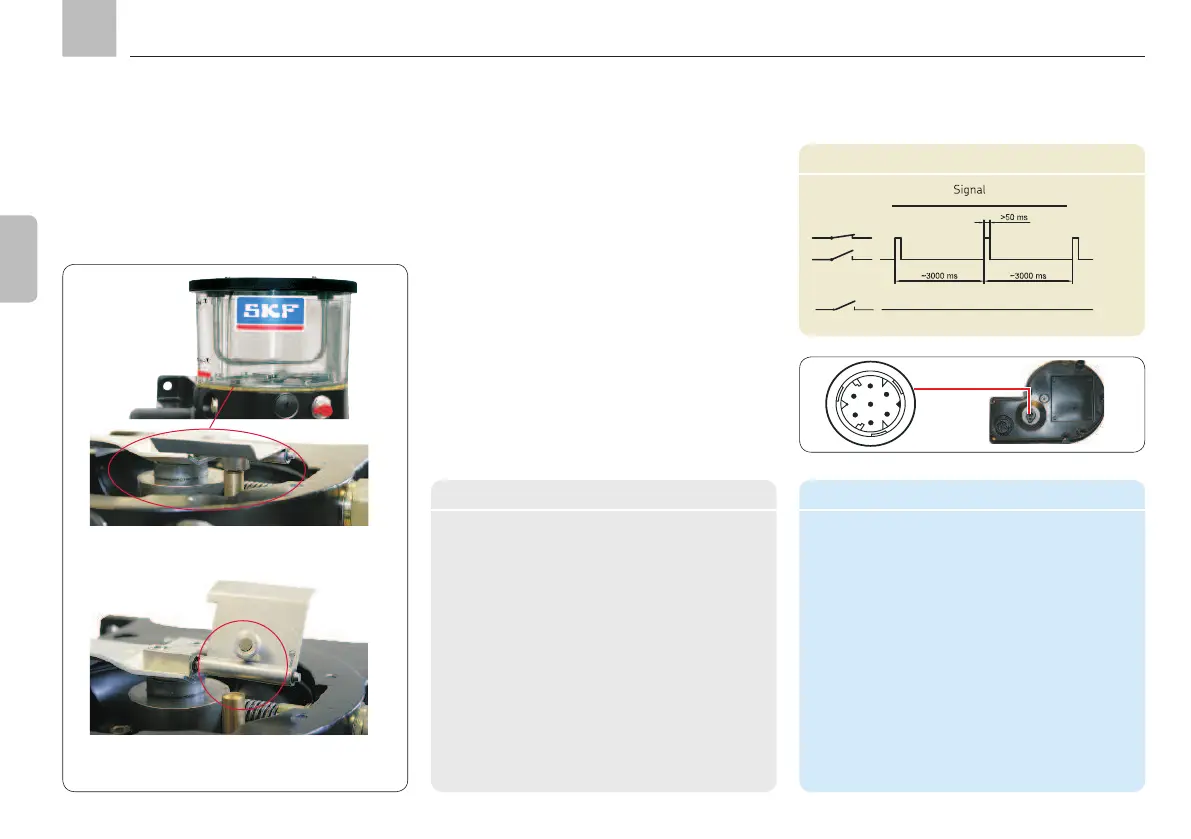

Contact W1 open

Contact W1 closed, go position

W1 block diagram

Function

Reservoir filled

Reservoir empty

W1 connector pin assignment (pump unit)

PIN Description

1 = 31 - Supply

voltage potential (0V, GND)

2 = 15 + Supply

voltage potential

3 = not assigned

4 = not assigned

5 = + Potential

6 = Signal (pulses)

7 = not assigned

Assembly instructions

KFG

Loading...

Loading...