Section 04 ENGINE

Subsection 03 (494, 583 AND 670 ENGINE TYPES)

04-03-7

NOTE:

Neither exhaust manifold nor cylinder

aligning tools (flat bars) must be installed on ex-

haust flanges to perform this procedure.

1. Place a 0.43 mm (.017 in) feeler gauge be-

tween cylinders and slide it back and forth to

have the good spacing along cylinders.

A. 0.43 mm (.017 in) feeler gauge

2. Apply Loctite 242 to screw threads. Properly

torque cylinders screws.

3. Lay down cylinder head and insert aligning pins

in holes as shown.

NOTE:

If pins can not be inserted in cylinder head

holes, enlarge them with a 8.75 mm (11/32 in) drill

bit.

4. Install 4 screws in center holes. Torque to 10

N•m (89 lbf•

in

).

1. Pins

2. Screws

5. Remove pins and install remaining screws.

6. Tighten all screws in the above-recommended

sequence and torque as specified.

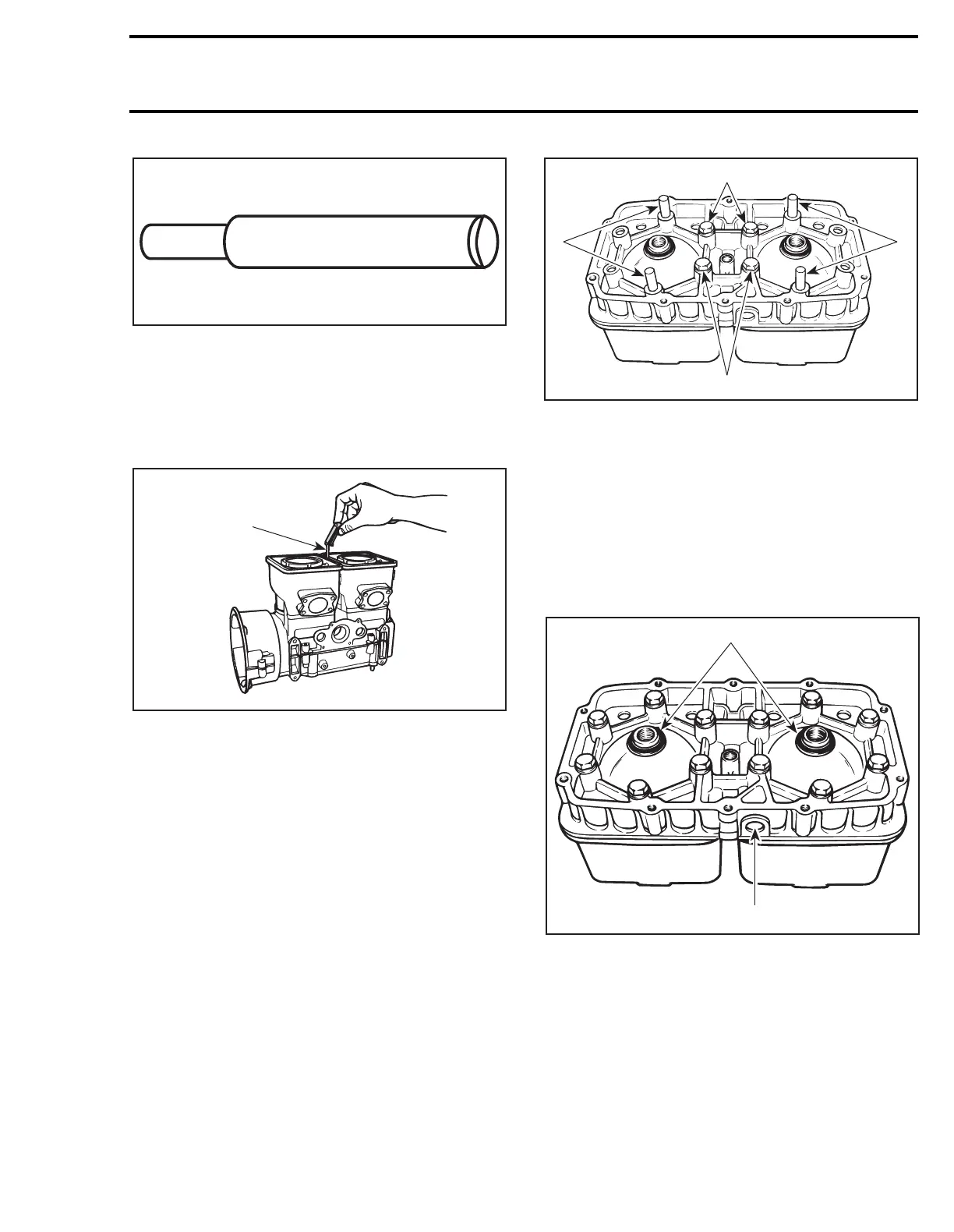

Position O-rings over cylinders then install cylinder

head with its temperature sensor hole on rotary

valve side. Install and torque screws to 29 N•m (21

lbf•ft) as per following illustrated sequence. Make

sure to install O-rings around spark plug holes.

TYPICAL

1. O-rings

2. Temperature sensor hole

A. Torque to 29 N•m (21 lbf•ft)

A00A1DA

A00A1FA

A

A00A1EA

2

2

1

1

A25C0CA

1

2

A

Loading...

Loading...