Section 05 TRANSMISSION

Subsection 06 (BRAKE)

05-06-5

ADJUSTMENT

Countershaft Bearing

S-Series

Insert countershaft (with brake disc) from chain-

case side through countershaft support (driven

pulley side), then insert into chaincase.

Install countershaft bearing

no. 19

and ensure

that countershaft is properly aligned, then tighten

3 retaining screws.

NOTE:

A misaligned countershaft will result in dif-

ficulty to center the bearing in its support.

Refer to DRIVE AXLE 07-05 then look

Chaincase

Perpendicularity Adjustment.

Torque castellated nut of upper sprocket to 53

N•m (39 lbf•ft).

Slide collar

no. 18

towards bearing and turn, by

hand, to engage the eccentric. This should require

about a quarter turn.

Turn collar in direction of countershaft rotation un-

til collar and inner race lock together.

Insert a punch into collar hole and strike sharply in

the same direction to lock firmly.

Apply Loctite 242 (P/N 413 7030 00) on set screw

threads, then tighten.

Close chaincase referring to CHAINCASE 05-07.

BLEEDING

Change brake fluid once a year.

Bleed brake system as follows:

Keep sufficient DOT 4 (DOT 3 for normal use)

brake fluid in reservoir at all times.

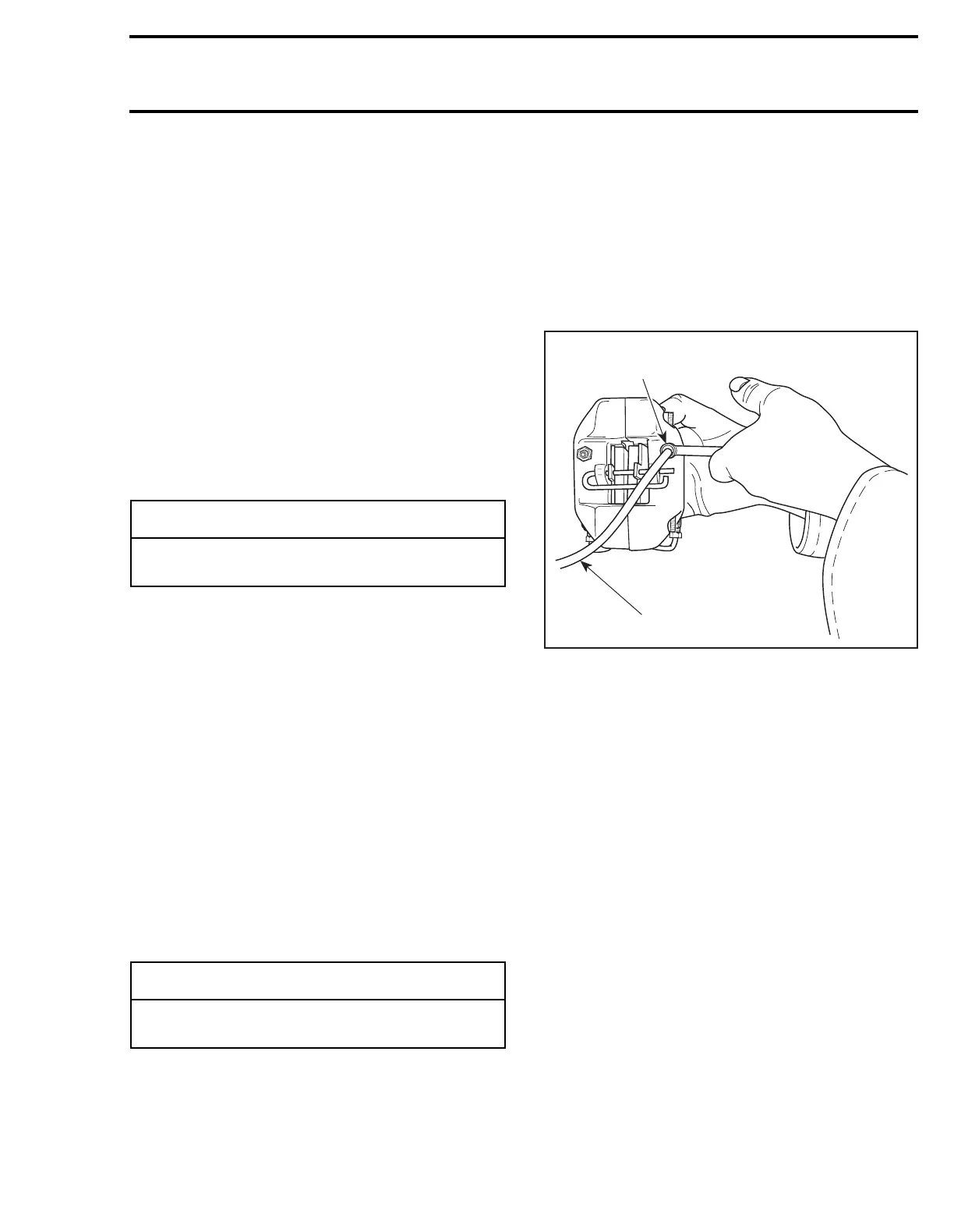

Install a hose on left side bleeder. Route this hose

to a container.

Pump a few times brake lever and while holding

brake lever depressed, open bleeder and check

for air to escape.

Repeat with the same bleeder until no air appears

in hose.

Proceed the same way with the right side bleeder.

1. Open bleeder

2. Clear hose to catch used brake fluid

Brake Light

There is no adjustment on these models. Check

that switch is securely installed.

-

CAUTION

Upper sprocket castellated nut must be

tightened

before

adjusting bearing collar.

-

CAUTION

Use only DOT 4 brake fluid for heavy duty or

racing applications.

A06D0JA

2

1

Loading...

Loading...