Section 04 ENGINE

Subsection 03 (494, 583 AND 670 ENGINE TYPES)

04-03-5

NOTE:

The following procedures can be done

without removing the engine from chassis.

CLEANING

Discard all gaskets and O-rings.

Clean all metal components in a non-ferrous met-

al cleaner.

Scrape off carbon formation from cylinder ex-

haust port, cylinder head and piston dome using a

wooden spatula.

NOTE:

The letters

AUS

(over an arrow on the pis-

ton dome) must be visible after cleaning.

Clean the piston ring groove with a groove cleaner

tool, or with a piece of broken ring.

DISASSEMBLY

Place a clean cloth over crankcase then with a

pointed tool inserted in piston notch, remove cir-

clip

no. 20

from piston

no. 21

.

To remove piston pin

no. 19

, use piston pin puller

(P/N 529 0290 00) as follows:

– Fully screw puller handle.

– Insert puller end into piston pin.

– Install adaptor (P/N 529 0236 00) then screw

extracting nut (LH threads).

– Hold puller firmly and rotate puller handle coun-

terclockwise to pull piston pin.

NOTE:

0.25 mm oversize piston and rings are

available if necessary.

RAVE System

NOTE:

RAVE stands for Rotax Adjustable Variable

Exhaust.

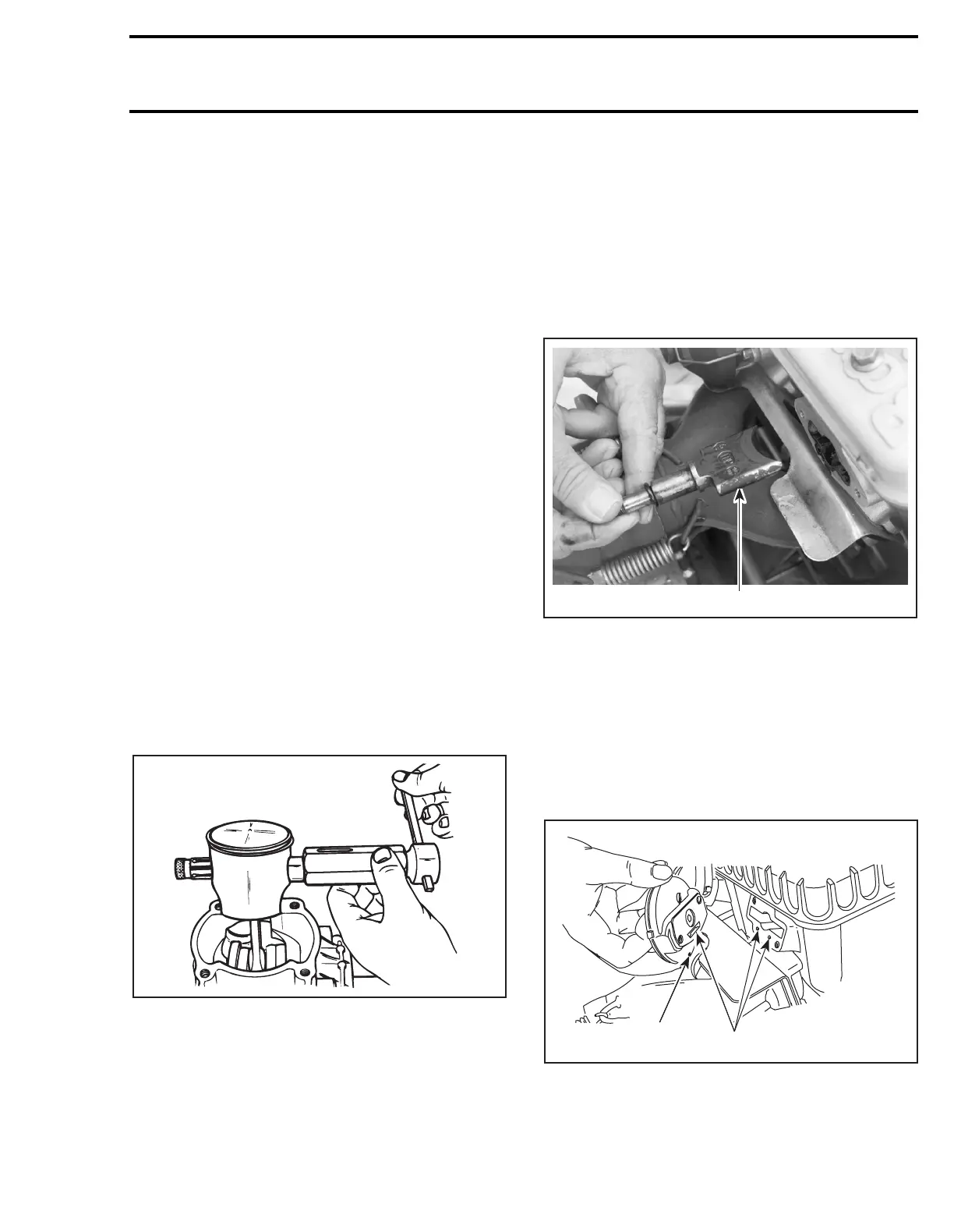

Remove spring clip

no. 3

, cover

no. 5

and spring

no. 6

.

Cut clamp

no. 8

(remove spring on 454) and un-

screw valve piston

no. 7

.

Spread clamp

no. 10

and remove bellows

no. 9

.

Remove cylindrical screws

no. 11

then valve rod

housing

no. 13

.

Pull out exhaust valve

no. 16

.

1. Exhaust valve

INSPECTION

Refer to ENGINE DIMENSIONS MEASUREMENT

04-04.

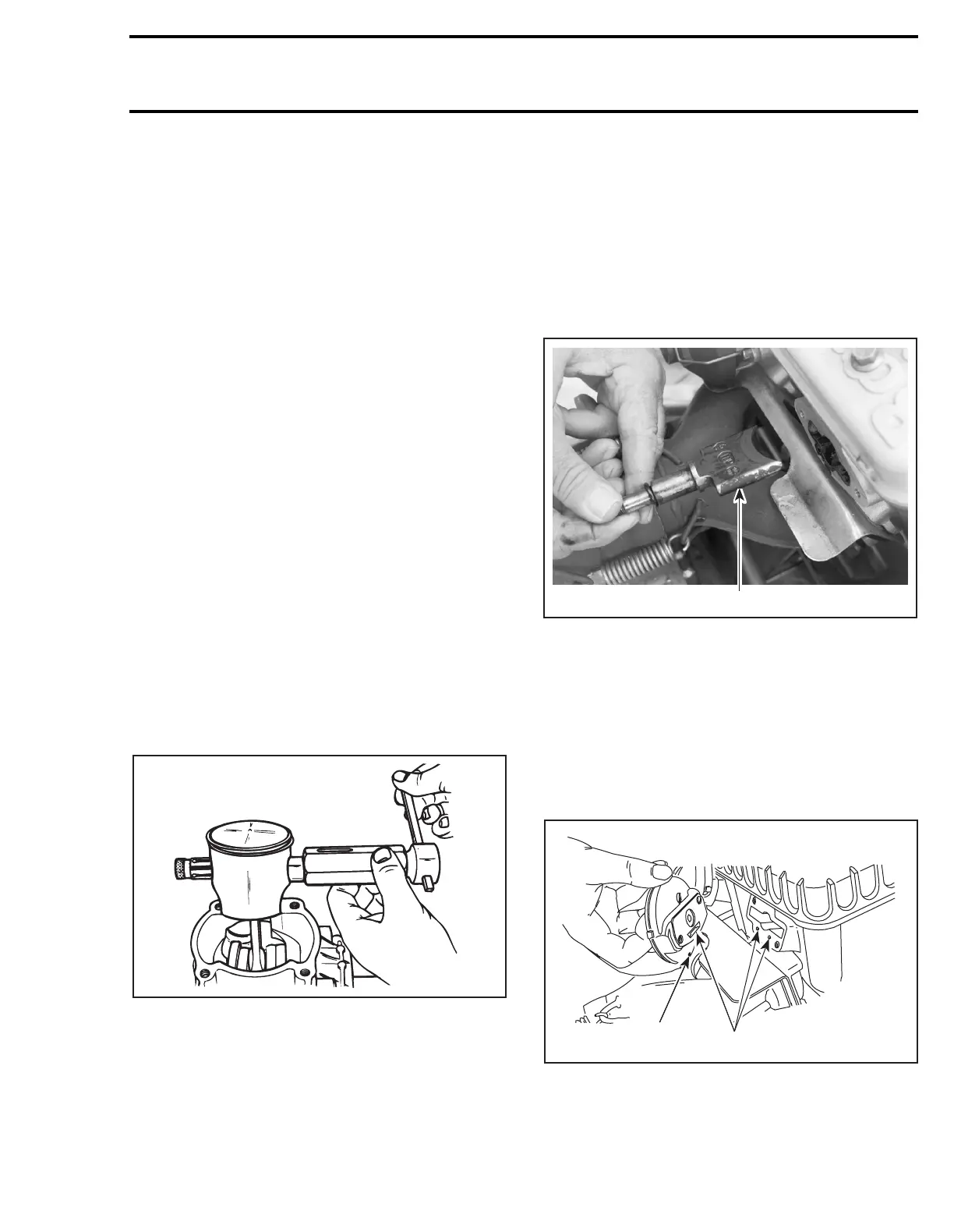

RAVE System

Check valve rod housing and cylinder for clogged

passages.

TYPICAL

1. Draining hole

2. Passages

A01B1AA

A03C1PA

1

1

2

A24C05A

Loading...

Loading...