Section 04 ENGINE

Subsection 11 (CARBURETOR AND FUEL PUMP)

04-11-5

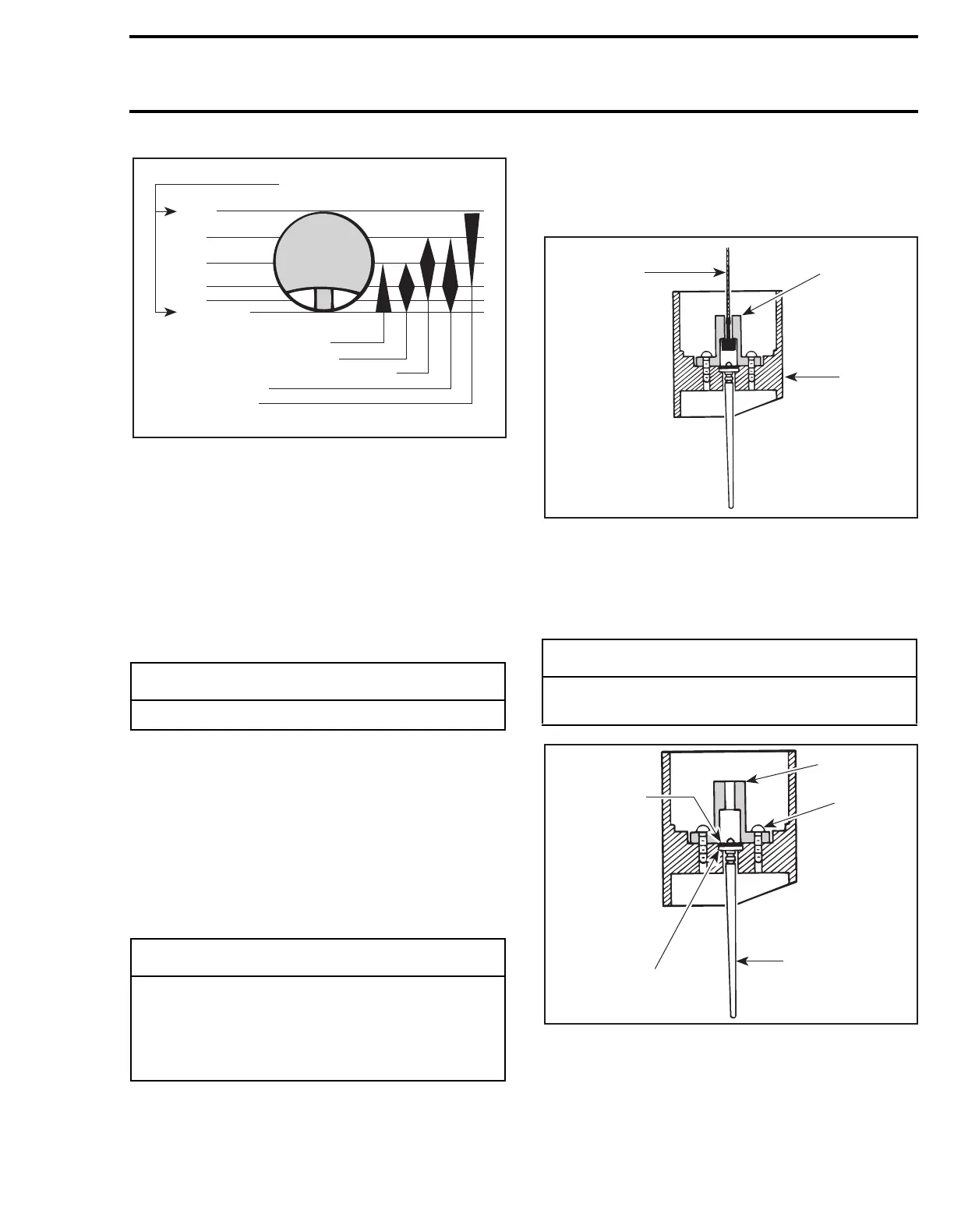

VIEW FROM AIR INTAKE OPENING

NOTE:

For fine tuning refer to TECHNICAL DATA

10 and to SPARK PLUG 06-03.

NOTE:

For high altitude regions, the

High Altitude

and Sea Level Technical Data Booklet

(P/N 484

0686 00 and 484 0545 00 for binder) gives infor-

mation about calibration according to altitude and

temperature.

INSTALLATION

To install carburetor on engine, inverse removal

procedure.

However, pay attention to the following:

– Inspect throttle cable and housing prior to in-

stallation.

On applicable models, make sure to align tab of

carburetor and air intake silencer (if applicable)

with notch of adaptor(s). On applicable models, in-

stall adaptor with up mark facing up.

Install clamps in a way that their tightening bolts

are staggered — not aligned.

Hook throttle cable into the needle retainer plate.

NOTE:

Do not obstruct hole in throttle slide when

installing needle retaining plate. This is important

to allow air escaping through and thus allowing a

quick response.

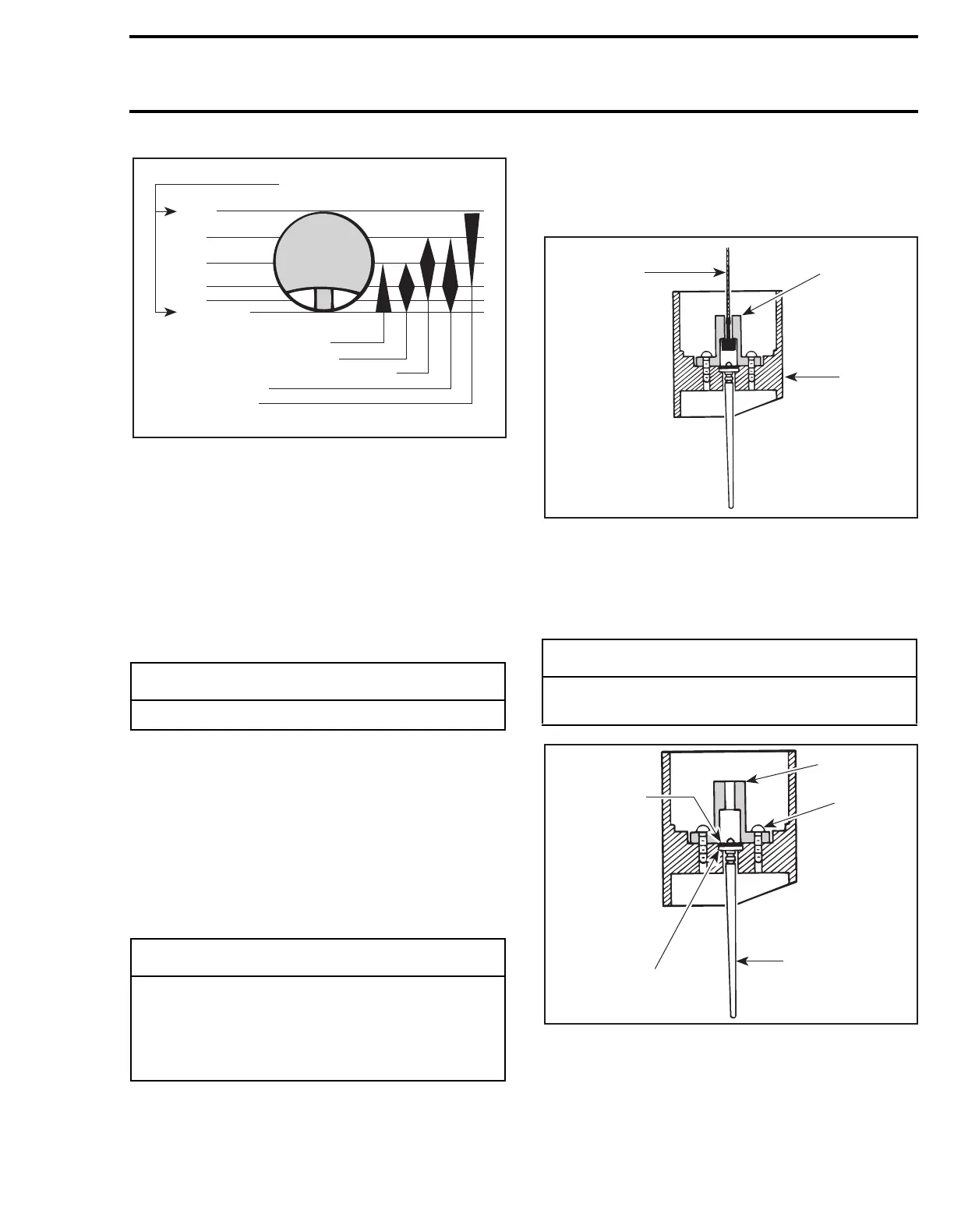

CENTER POST TYPE

1. Throttle cable

2. Needle retaining plate

3. Throttle slide

Make sure the nylon packing

no. 4

is installed on

all applicable throttle slides.

CENTER POST TYPE

1. E-clip

2. Needle retaining plate

3. Screw

4. Needle

5. Nylon packing

-

CAUTION

Never allow throttle slide(s) to snap shut.

-

CAUTION

The rubber flange must be checked for

cracks and/or damage. At assembly, the

flange must be perfectly matched with the

air intake manifold or severe engine damage

will occur.

Throttle slide openings

Pilot jet and air screw13,6,

Throttle slide cut-away5,

Needle taper and needle position3,

Needle jet14,

Main jet8,

A00C04A

Wide

open

Close

3/4

1/2

1/4

1/8

-

CAUTION

Serious engine damage can occur if this no-

tice is disregarded.

A00C1TA

1

2

3

2

3

4

5

1

A00C3MA

Loading...

Loading...