Section 04 ENGINE

Subsection 04 (LEAK TEST AND ENGINE DIMENSION MEASUREMENT)

04-04-11

TYPICAL

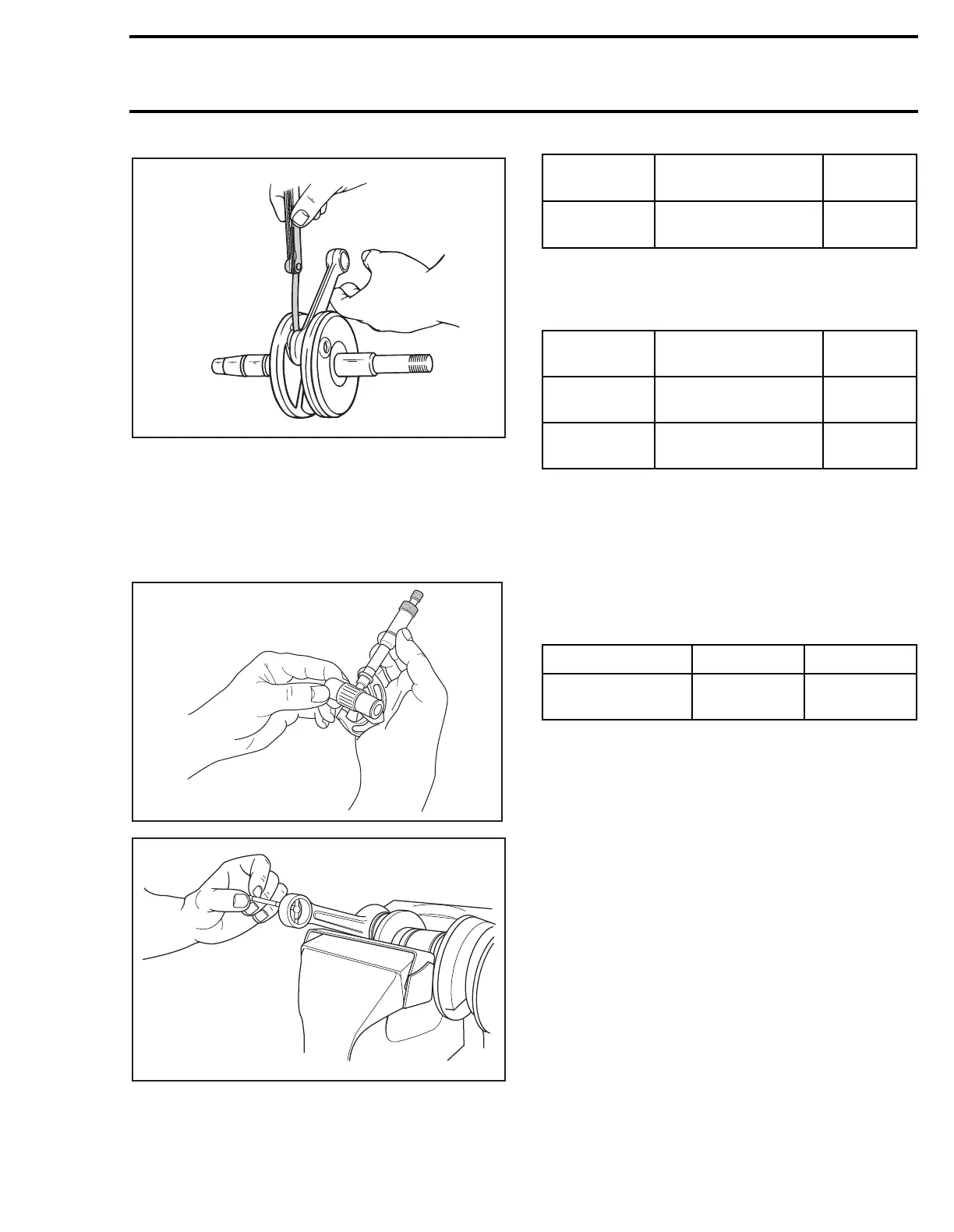

CONNECTING ROD/PISTON PIN

CLEARANCE

Measure piston pin with its needle bearing. Com-

pare to inside diameter of connecting rod.

CONNECTING ROD/CRANKPIN

CLEARANCE

CRANKSHAFT END-PLAY

443, 494, 503 and 670 Engine Types

End-play is not adjustable but it should be be-

tween 0.10 - 0.30 mm (.004 - .012 in).

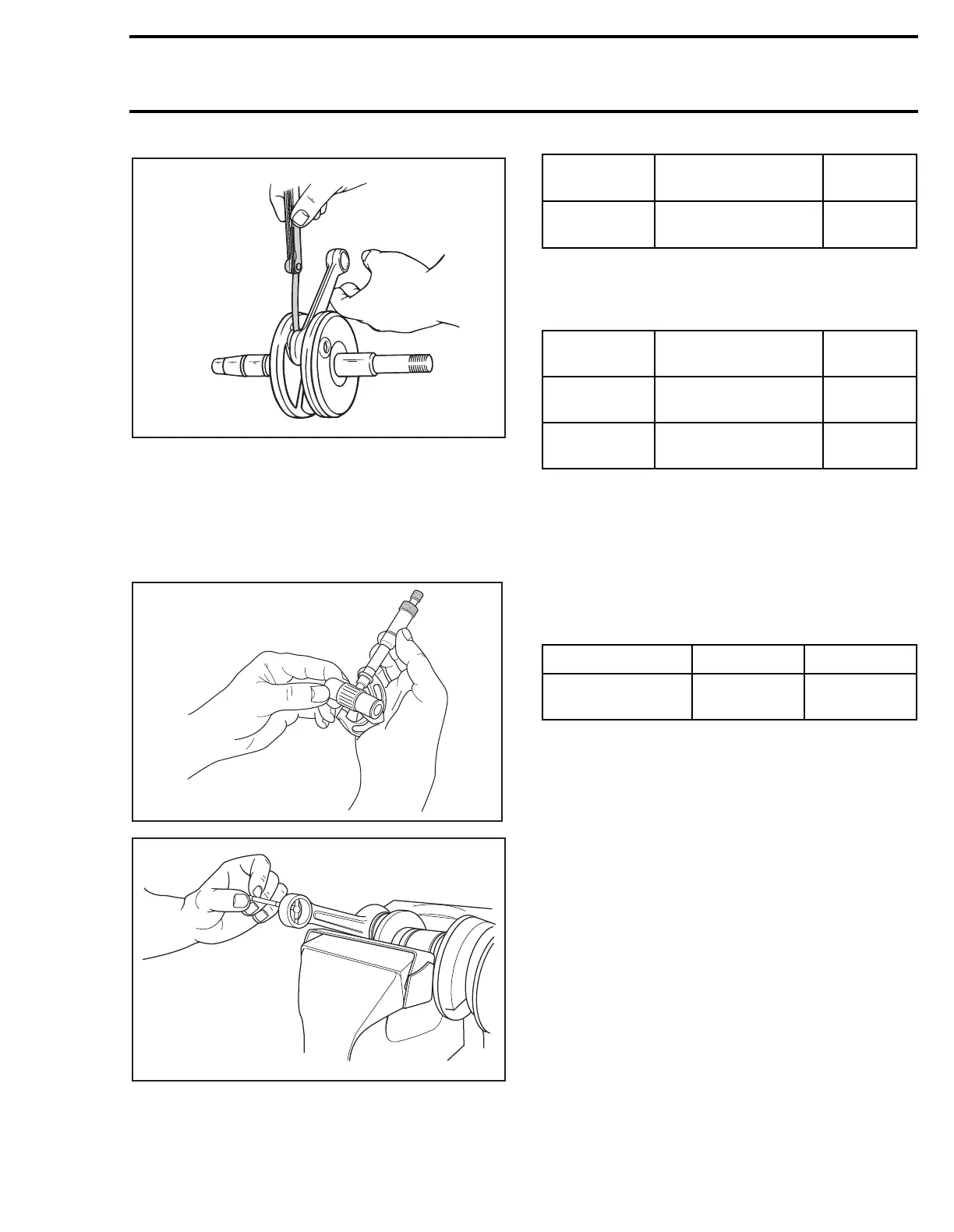

CRANKCASE/ROTARY VALVE GAP

First Method

To measure this gap use a feeler gauge inserted

between rotary valve and upper crankcase with

the rotary valve cover in place

without its O-ring

.

Check the most surface as possible. Follow the

same procedure with the lower crankcase.

A01C0SA

A01C3GA

A01C3HA

ENGINE

TYPE

NEW PARTS

MIN. - MAX.

WEAR

LIMIT

All

0.03 - 0.012 mm

(.0001 - .0005 in)

0.015 mm

(.0006 in)

ENGINE

TYPE

NEW PARTS

MIN. - MAX.

WEAR

LIMIT

443 and 503

0.020 - 0.033 mm

(.0008 - .0013 in)

0.05 mm

(.0020 in)

494, 583

and 670

0.038 - 0.050 mm

(.0015 - .0020 in)

0.06 mm

(.0024 in)

ENGINE TYPE MINIMUM MAXIMUM

Liquid cooled

engines

0.27 mm

(0.011 in)

0.40 mm

(0.016 in)

Loading...

Loading...